Installation, Input connection, Input fuse and supply wire considerations – Lincoln Electric IM905 POWER WAVE 455M User Manual

Page 13: Warning, Electrode and work cable connections, Caution

A-3

INSTALLATION

A-3

INPUT CONNECTION

Only a qualified electrician should

c o n n e c t t h e i n pu t l e a d s t o t h e

P o w e r

W a v e

45 5M

( C E ) .

Co n n ec ti o n s s h o u l d be m a de i n

a c c o r d a n c e w i t h a l l l o c a l a n d

national electrical codes and the connection dia-

gram located on the inside of the reconnect/input

access door of the machine. Failure to do so may

result in bodily injury or death.

-------------------------------------------------------------

Use a three-phase supply line. A 45 mm (1.75 inch)

diameter access hole for the input supply is located on

the upper left case back next to the input access door.

Connect L1, L2, L3 and ground according to the Input

Supply Connection Diagram decal located on the

inside of the input access door or refer to Figure A.1.

INPUT FUSE AND SUPPLY WIRE

CONSIDERATIONS

Refer to the Technical Specifications at the beginning of

this Installation section for recommended fuse and wire

sizes.

Fuse the input circuit with the recommended super

lag fuse or delay type breakers (also called “inverse time” or

“thermal/magnetic” circuit breakers). Choose an input and

grounding wire size according to local or national electrical

codes. Using fuses or circuit breakers smaller than recom-

mended may result in “nuisance” shut-offs from welder

inrush currents, even if the machine is not being used at

high currents.

NOTE: Turn main inpu

ut power to the

e machine O

OF

FF

F b

be

eforre p

pe

erforrm

miin

ng c

co

on

nn

necttiio

on

n p

pro

oc

ce

ed

du

urre

e.. F

Fa

aiillu

urre

e tto

o d

do

o sso

o w

wiillll

rre

essu

ulltt iin

n d

da

am

ma

ag

ge

e tto

o the machine.

WARNING

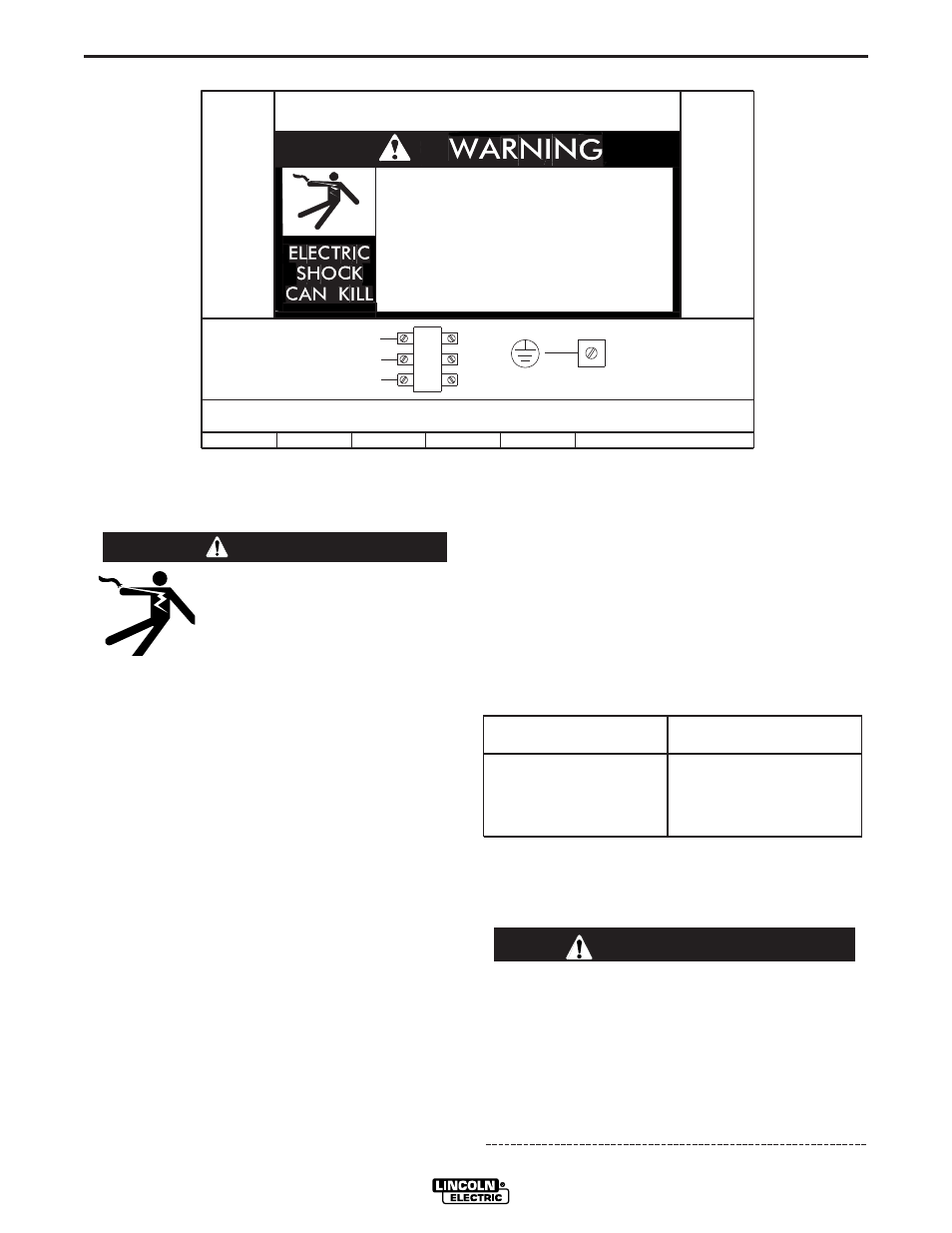

FIGURE A.1 - CONNECTION DIAGRAM ON CONNECTION/INPUT ACCESS DOOR

ELECTRODE AND WORK CABLE

CONNECTIONS

Connect a work lead of sufficient size and length (Per

Table 1) between the proper output terminal on the

power source and the work. Be sure the connection to

the work makes tight metal-to-metal electrical contact. To

avoid interference problems with other equipment and to

achieve the best possible operation, route all cables

directly to the work and wire feeder. Avoid excessive

lengths and do not coil excess cable.

Minimum work and electrode cable sizes are as follows:

TABLE A.1

Current (60% Duty Cycle) MINIMUM COPPER

WORK CABLE SIZE AWG

Up To-30 m (100 Ft.

Length)

400 Amps

67 mm

2

(2/0)

500 Amps

85 mm

2

(3/0)

600 Amps

85 mm

2

(3/0)

NOTE: K1796 coaxial welding cable is recommended to

reduce the cable inductance in long cable lengths. This

is especially important when Pulse welding up to 350

amps.

When using inverter type power sources like the

Power Waves, use the largest welding (electrode and

work) cables that are practical. At least 67 mm

2

2/0

copper wire - even if the average output current

would not normally require it. When pulsing, the

pulse current can reach very high levels. Voltage

drops can become excessive, leading to poor weld-

ing characteristics, if undersized welding cables are

used.

CAUTION

W / L3

V / L2

U / L1

THE LINCOLN ELECTRIC CO. CLEVELAND, OHIO U.S.A.

XA

S24190

use or service this equipment.

Do not touch electrically live parts.

removed.

Only qualified persons should install,

Do not operate with covers

inspecting or servicing machine.

Disconnect input power before

.

.

.

.

CR1

INPUT SUPPLY CONNECTION DIAGRAM

POWER WAVE 455M (CE)