Installation – Lincoln Electric IM772 K1780-2 Power Feed 10 Robotic User Manual

Page 11

A-4

INSTALLATION

POWER FEED 10 ROBOTIC

A-4

CONTROL CABLE SPECIFICATIONS

It is recommended that genuine Lincoln control cables

be used at all times. Lincoln cables are specifically

designed for the communication and power needs of

the Power Wave / Power Feed system. The use of

non-standard cables, especially in lengths greater

than 25 feet, can lead to communication problems

(system shutdowns), poor motor acceleration (poor

arc starting) and low wire driving force (wire feeding

problems).

Lincoln control cables are copper 14 conductor cable

in a SO-type rubber jacket.

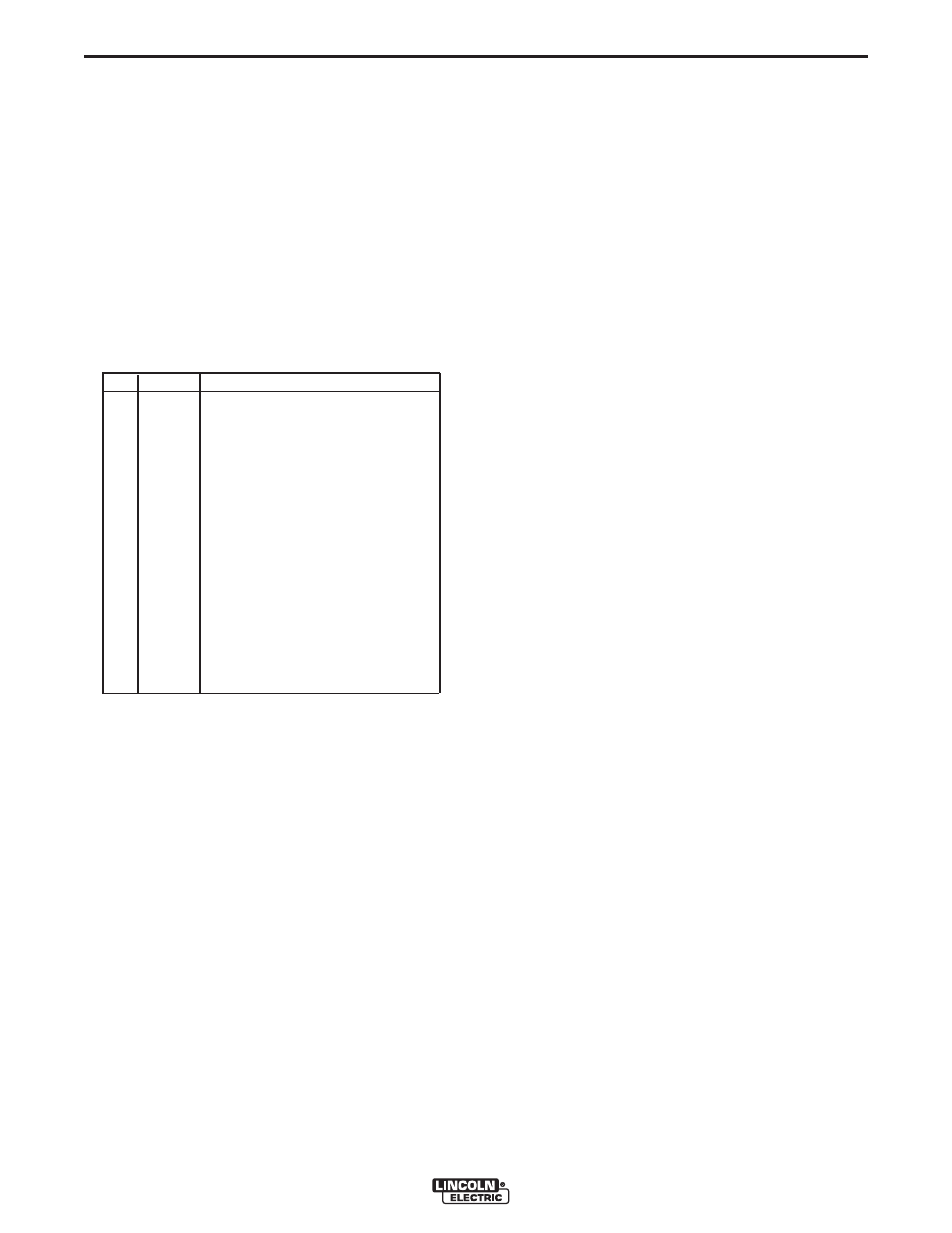

TABLE 2 (CONNECTOR WIRING)

AVAILABLE CABLE ASSEMBLIES:

Use K1785 series Control Cables.

WIRE DRIVE GEAR RATIO (HIGH OR LOW

SPEED)

The speed range capability and drive torque of the

Power Feed wire drives can be easily and quickly

changed by changing the external drive gear. The

Power Feed Wire Feeders are shipped with both high

speed and a low speed gears. As shipped from the

factory, the low speed (high torque) gear is installed

on the feeder. If this is the desired gear ratio, no

changes need be made.

SELECTING THE PROPER GEAR RATIO

See Specification Section A-1 for feed speed and wire

size capabilities with high and low speed gear ratios.

To determine whether you should be using the high or

low speed ratio use the following guidelines:

• If you need to operate at wire feed speeds above

800 IPM (20 m/m), you will need to install the high

speed gear (large 30 tooth, 1.6 inch diameter gear).

• If you do not need to run at wire feed speeds in

excess of 800 IPM (20 m/m), you should use the low

speed gear (small, 20 tooth, 1.1 inch diameter gear).

Using the low speed ratio will provide the maximum

available wire driving force.

The full range of wire feed speed listed in Section A-1

may not be useable for all welding programs. Check

your welding software to make sure the desired WFS

falls within the welding software limits.

Pin

A

B

C

D

E

F

G

H

J

K

L

M

N

Lead #

539

541

552

553

515

500

842

843

67

Function

Motor "+"

Motor "-"

+40vdc for solenoid

Solenoid Input

Reserved for future use

Reserved for future use

Tach 2A differential signal

Tach 2B differential signal

Reserved for future use

Tach 1A differential signal

Tach 1B differential signal

Reserved for future use

Voltage sense lead