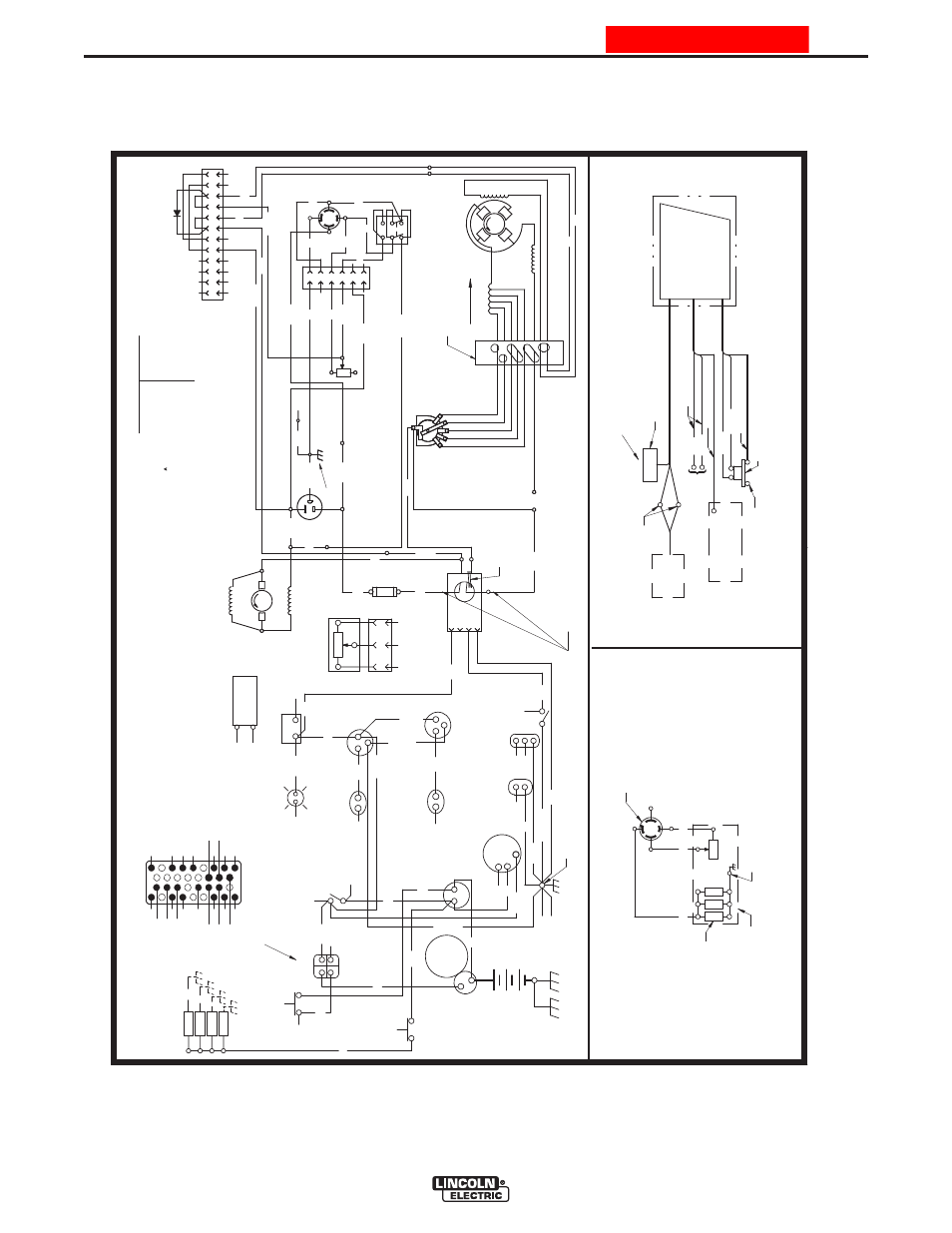

Diagrams, Pipeliner 200d kubota, Enhanced diagram – Lincoln Electric IM844 PIPELINER 200D KUBOTA User Manual

Page 27

F-1

DIAGRAMS

F-1

PIPELINER 200D KUBOTA

S

B

W

IRE

FE

ED

M

ODU

LE

(O

P

TI

O

N

A

L)

60

8

60

9

+

PI

PEL

IN

ER

200D W

IRI

N

G

D

IA

G

R

A

M

A

M20464

PLUG P

5

IN

LI

NE CONNE

CT

ORS

W.

F.

M

.

CONT

ROL

PAN

EL

CONNE

CT

T

O POS.

& NEG.

OUT

PU

T TE

RM

IN

ALS

POS

.

NEG.

#8 L

EA

D

#2

H

EAVY

LEAD

#2

H

EA

VY

L

EA

D

NEGA

TI

VE

C

V

OU

TP

UT

T

ERM

IN

AL

PA

NE

L

CONNEC

T T

O

NE

G.

BRUS

H HOLDER

25

0 AM

P

TH

ER

M

OS

TAT

ASS

EM

BL

Y

MA

C

HI

N

E MU

ST N

OT BE R

U

N

NI

N

G

WHE

N MA

KIN

G TH

ES

E C

ON

N

ECTI

ON

S.

64

62

GROUND

TO BA

SE

GROUN

D

TO

ENGI

NE

21

2C

GND-

B

84

2

60

A

GROUN

D SC

REW

NE

AR

EN

GINE GAUGE

S

60

S

I

G

21

2A

84

1B

WA

TE

R

TE

MP

GAUGE

GND -N

GND-

M

51

C

GL

OW

PLUG

53

52

A

52

B

ST

AR

T

61

ENGI

NE

FAI

LURE

LAMP

84

1A

ST

AR

T R

EL

AY

55

IG

NI

TI

ON

SW

IT

CH

51

A

51

B

21

2D

EN

GINE HOUR

ME

TE

R

-

+

58

84

1

S

I

G

OI

L

PR

ES

SURE

GAU

GE

21 2B

50

A

-

+

AM

M

ET

ER

IG

B

L

51

21

2E

AL

TE

RN

AT

OR

94

EN

GINE

SP

EE

D

SE

NSOR

93

WA

TE

R

TEMP. SE

NS

OR

44

WG

TE

MP

.

SW

IT

CH/

SE

NDE

R

43

54

WK

G

20

0

OIL P

RE

S.

SW

ITCH/

SE

ND

ER

1 3 4 2

START

ING

MOT

OR

WI

RE

F

EED

MODULE

GL

OW

PLUGS

PLUG FOR

RE

M

OTE

CONTROL

PO

TE

NT

IO

M

ET

ER

CO

NN

ECT

T

O

CA

SE

RE

M

OT

E CON

TO

L

PO

TE

NT

IO

M

ETE

R BO

X

RE

SI

ST

ORS

K924-5 R

EMOTE

C

O

NT

R

OL (

O

PTION

AL)

Y

X

B

G

W

* *

*

*

*

*

*

*

*

* *

*

*

*

**

*

*

RP

M

CONT

ROL

1

2

3

86

88

87

*

LE

AD

S C

ONNE

CT

ED

T

O E

NG

INE

C

ONT

RO

L

UNI

T,

S

EE

D

ET

AI

L

'

NEU

TRAL

BO

NDED TO F

RAME.

NEU

TR

E RACC

ORDE AU

BA

TI

.

CO

NT

ROL

PA

NEL COMPONE

NT

S

SHOW

N

AS

V

IEW

ED

F

ROM

RE

AR.

LE

AD C

OLOR COD

E

G-

GR

EE

N

N-

BR

OWN

U-

BL

UE

W-

WH

IT

E

Y-

YE

LL

OW

B-

BLAC

K OR

GR

AY

R-

RED

OR

PI

NK

56

57

AC

TU

ATOR

84

4A

ID

LER SW

IT

CH

*

84

4

60

E

60

F

EN

GINE CONT

ROL

UNI

T CONN

ECT

OR

DETAI

L

BA

TT

ER

Y

69

*

NO

TE

: L

EA

D 7

0A

IS

L

EFT

OP

EN

A

ND

W

IR

E

TI

ED

IN

TO

H

AR

NE

SS

.

84

1

ON M

ACHI

NE

, R

EMOVE

PLUG "

P1

0"

F

ROM

CONNE

CT

OR "

J5

".

CO

NN

EC

T

"P

5"

O

N

W

.F.

M.

TO

C

ON

NE

CT

OR

"J

5"

O

N M

AC

HI

NE

.

50

WI

RE

-T

IE

D T

O W

IR

IN

G

HA

RNE

SS

BE

HI

ND

CO

NT

ROL

PA

NEL

18

88

55

56

87

93

52

B

60

F

86

58

69

51

B

61

60

E

44

21

2D

64

54

94

70

A

84

4A

70

B

57

1

10

26

34

25

17

9

72

0C

F1 15

A

61

0D

42 60

2A

1 2 3 4 5 6

60

0A

41

60

0B

61

0

60

2B

J5

J8

P1

0

N

U

RH

EOSTAT

1

2

3

4

5

6

7

8

9

10

11

12

73

0A

72

0A

60

0C

RECE

PTACLE

-

61

0C

GND-

T

Y

42

60

2

W

G

41

W

R

X

60

0

+

P9

72

0B

73

0B

GROUND

S

CRE

W

NE

AR

F

U

S

E

61 0B

67

B

SHU

NT

SE

RI

ES

EX

CI

TE

R B

RUSHE

S

SHOW

N A

S

VI

EW

ED

F

ROM

CONTROL

PAN

EL

U

N

A

5

4

3

2

1

SE

RI

ES

SHUNT

SE

LE

CT

OR

SW

IT

CH

IN

TE

RP

OL

E

GENERATOR L

E

AD B

LOCK

SHOWN A

S

VIE

W

ED W

ITH

ENGINE IN THI

S DIRECT

ION

+

+

-

-

SW

IT

CH FO

R L

OCAL

O

R

REMO

TE

CONT

RO

L SHO

W

N

IN

LO

CA

L

PO

SI

TI

ON

NEGA

TI

VE

(CC-

)

PO

SI

TI

VE

(C

C+

) &

(C

V+

W

IT

H W

.F.

M.)

70

C

*

67

A

70

B

3 T

UR

NS

TH

ESE

L

EADS M

UST

BE ROUT

ED T

HRU

CURRENT

SENSOR I

N SAME (

CURRENT

F

LOW)

DI

RECT

IO

N AS

SHO

W

N.

FOR CODES 1

1

1

14, 1

1316

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diag

ram for a particular code is pasted inside the

machine on one of the enclosure panels. If the diagram is illegible, write to the Service Department for a replacement. Give

the equipment code number.

ENHANCED DIAGRAM