Troubleshooting, Caution – Lincoln Electric IM475 MAGNUM 550 GUN & CABLE User Manual

Page 20

E-2

TROUBLESHOOTING

E-2

MAGNUM® 550

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

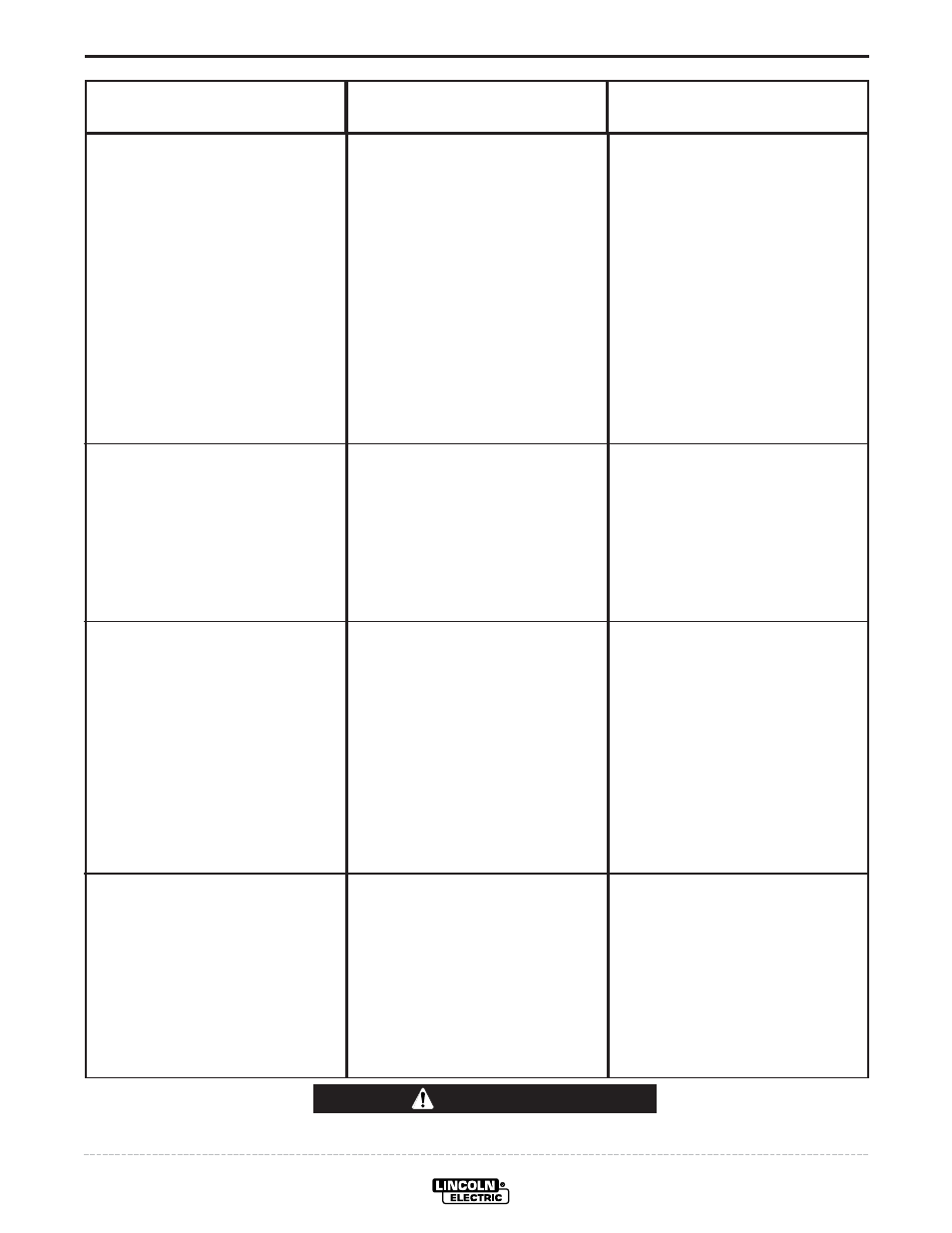

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Drive rolls turn, but wire will not feed or

wire feeding is rough.

Variable or “hunting” arc.

Poor arc striking with sticking or “Blast-

offs”, weld porosity, narrow and ropy

looking bead, or electrode stubbing into

plate while welding.

Tip seizes in diffuser.

a. Gun cable kinked and/or twisted.

b. Wire jammed in gun and cable.

c. Incorrect drive rolls and guide tubes.

d. Gun cable liner dirty.

e. Worn drive rolls.

f. Electrode rusty and/or dirty.

g. Worn or improper size cable liner.

h. Partially flashed, melted, or improper

size contact tip.

i.

Incorrect diffuser.

a. Contact tip worn or incorrect size.

b. Worn or undersize ground cables or

poor ground connections.

c. Loose electrode connections.

a. Improper procedures or techniques.

b. Improper gas shielding.

a. Tip overheating due to prolonged or

excessive high current and/or duty

cycle welding.

a. Keep as straight as possible. Inspect

cable and replace if necessary.

b. Remove wire from gun and cable -

feed in new wire. Note any obstruc-

tion. Replace liner if necessary.

c. Be sure the wire diameter being used

is stamped on drive rolls and guide

tubes. Replace if necessary.

d. Clean liner or replace.

e. Replace or reverse split drive roll

type.

f. Replace the electrode if it is rusty.

g. Replace cable liner.

h. Replace the contact tip.

i.

Be sure diffuser size is correct for the

electrode being used.

a. Replace contact tip.

b. Inspect - repair or replace as neces-

sary.

c. Be sure the following connections are

tight: electrode cable to wire feeder

and power source, work cable to

power source and work, gun cable to

wire feeder contact block, gun nozzle

to body, and contact tip to nozzle.

a. See “Gas Metal Arc Welding” (GS-

100).

b. Clean gas nozzle, Make certain that

gas diffuser is not restricted. Make

certain that gas cylinder is not empty

or turned off. Make certain gas sole-

noid valve is operating and gas flow

rate is proper. Remove gun liner and

check rubber seal for any sign of

deterioration or damage. Be sure set

screw in brass connector is in place

and tightened against the liner bush-

ing.

a. Do not exceed current and duty cycle

rating of gun. A light application of

high temperature antiseize lubricant

(such as Lincoln E2067 Graphite

Grease) may be applied to tip

threads.