Troubleshooting, Caution – Lincoln Electric IM663 RED-D-ARC D300K 3+3 User Manual

Page 24

E-3

TROUBLESHOOTING

E-3

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

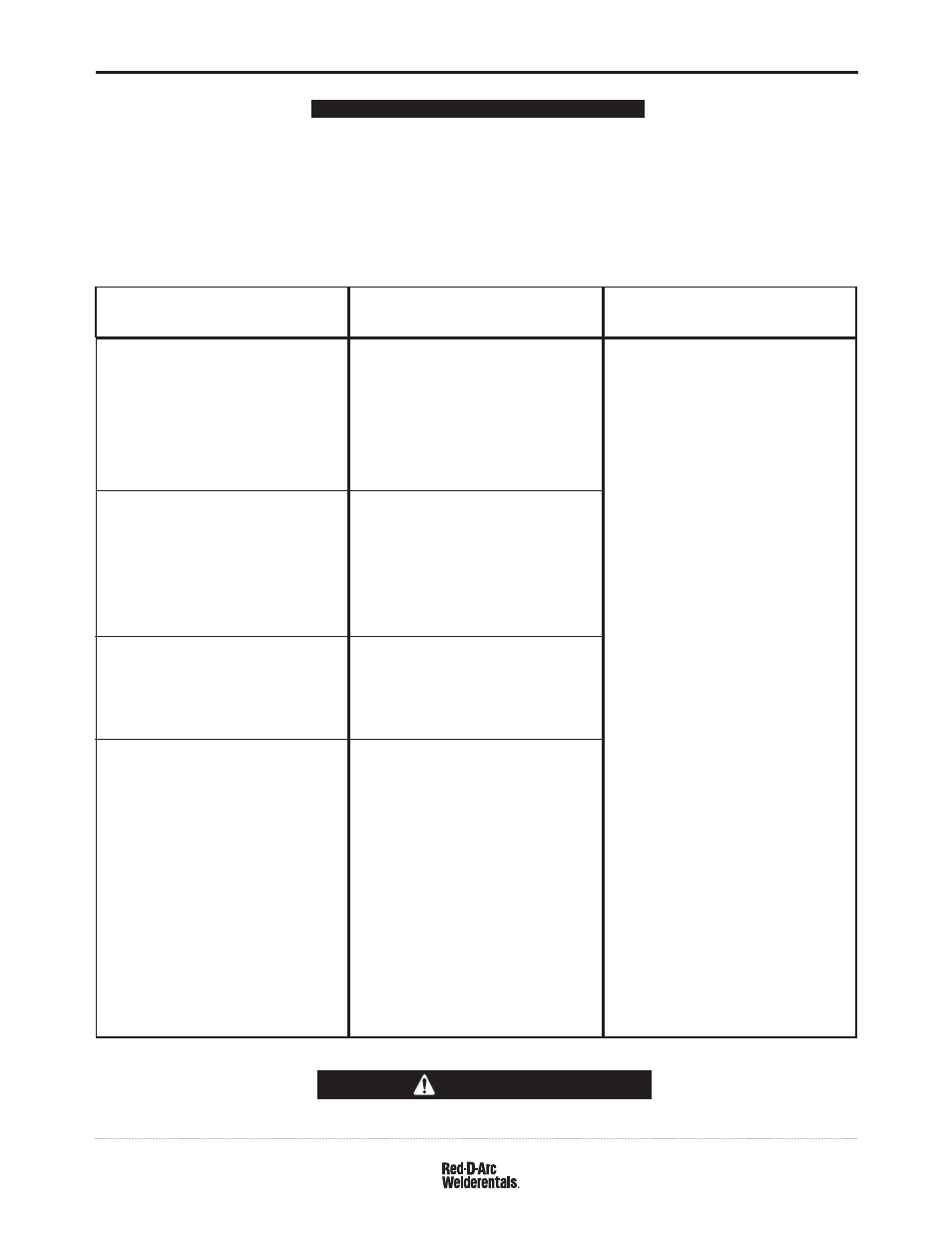

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Welding arc is loud and spatters

excessively.

Welding current too great or too

small compared to indication on the

dial.

Arc continuously pops out.

1. Current setting may be too high.

Check setting and current output

with ammeter.

2. Polarity may be wrong. Check

polarity. Try reversing polarity or

try an electrode of the opposite

polarity.

1. Exciter output low causing low

output compared to indication.

Check exciter field circuit.

2. Operating speed too low or too

high. Adjust speed screw on gov-

ernor. (High idle - 1800 RPM)

1. “Current Range Selector” switch

may be set at an intermediate

position. Set the switch at the cen-

ter of the current range set at an

intermediate position desired.

If all recommended possible areas of

misadjustment have been checked

and the problem persists, Contact

your local Authorized Field

Service Facility.

(1) FLASHING

THE

FIELDS:

1.

Stop the engine welder and remove the cover from the exciter.

2.

Turn the “Fine Current Adjustment” (rheostat) to “100” on the dial.

3.

Using a 12 volt automotive battery, connect itʼs negative terminal to the negative brush holder.

The negative brush holder is the one nearest to the rotor lamination. See the wiring diagram. With

the engine NOT running, touch the positive battery terminal to the positive brush holder. Remove

the battery from the circuit.

4.

Replace the exciter cover. Start the welder and the generator voltage should build up.

D300K 3+3

WELDER TROUBLESHOOTING