Operation – Lincoln Electric IM700 Commander 300 User Manual

Page 27

B-10

OPERATION

B-10

WIRE FEED (CONSTANT VOLTAGE) WELDING

Connect a wire feeder to the Commander 300 and set

welder controls according to the instructions listed earlier

in this section.

The Commander 300 in the

”

WIRE WELDING

”

position,

permits it to be used with a broad range of flux cored wire

(Innershield and Outershield) electrodes and solid wires

for MIG welding (gas metal arc welding). Welding can be

finely tuned using the

“

ARC CONTROL

”

.

Electrodes suitable for use are: NR-311, NS-3M, NR-207,

NR-203 Ni 1%, NR-204-H.

Electrodes suitable for use are: 0S-70, 0S-71M.

Electrodes suitable for wires for MIG welding are: .035 (0.9

mm), .045 (1.1 mm) and .052 (1.3 mm), L-50 and L-56,

.035 (0.9 mm) and .045 (1.1 mm) Blue Max MIG 308 LS.

For any electrodes, including the above recommenda-

tions, the procedures should be kept within the rating of

the machine. For additional electrode information, see

Lincoln publications N-675, GS-100 and GS-210.

ARC GOUGING

For optimal performance when arc gouging, set the

Commander 300

’

s

“

WELD MODE

”

switch to the

“

CC -

STICK

”

position, and the

“

ARC CONTROL

”

to 10.

Set the

“

OUTPUT

”

knob to adjust output current to the

desired level for the gouging electrode being used

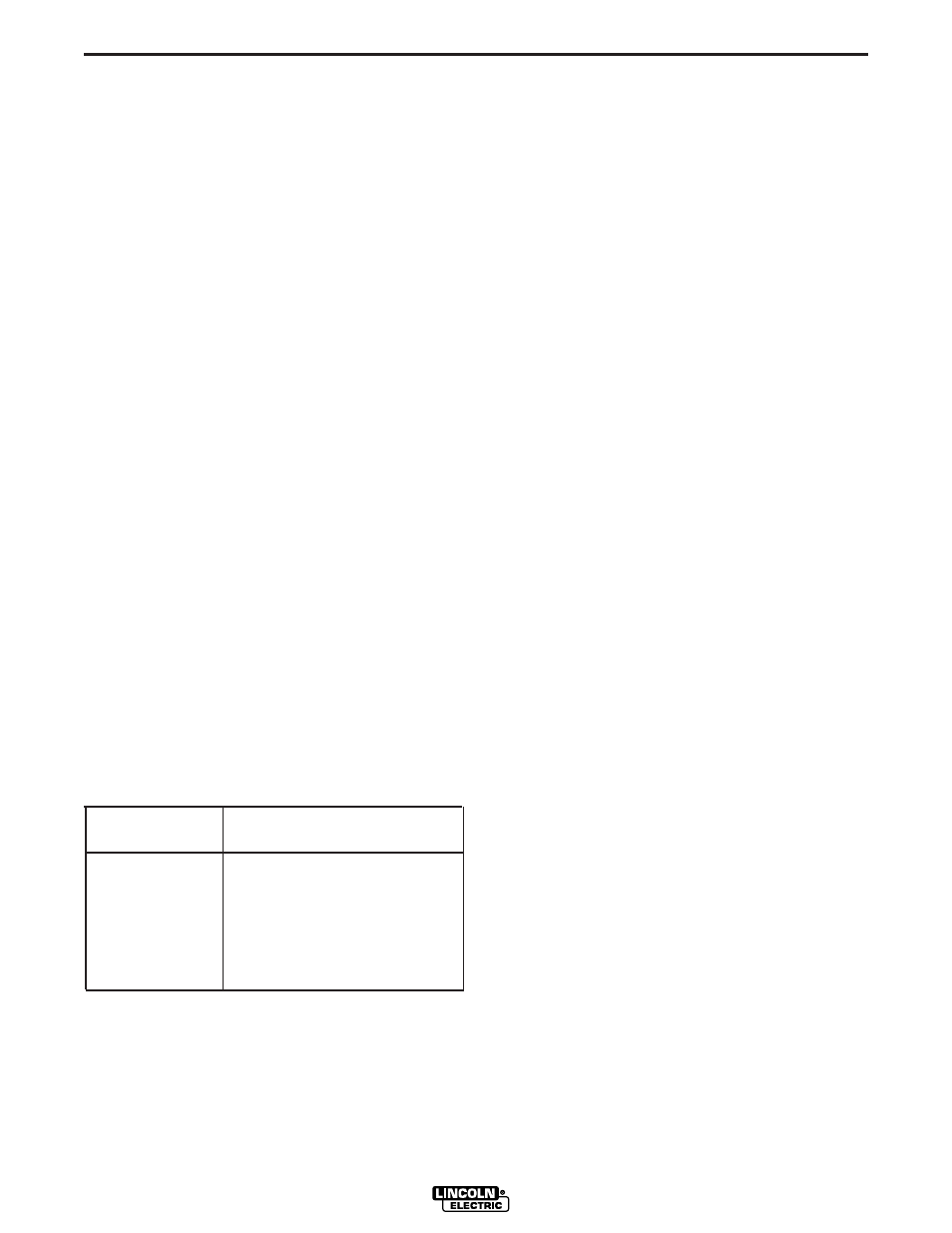

according to the ratings in the following table:

* Maximum current setting is limited to the Commander

300

’

s maximum of 375 Amps.

PARALLELING

When paralleling machines in order to combine their

outputs, all units must be operated in th CC - STICK

mode only. To achieve this turn the WELD MODE

switch to the CC - STICK position. Operation in other

modes may produce erratic outputs, and large output

imbalances between the units.

COMMANDER 300

ELECTRODE CURRENT RANGE

DIAMETER (DC,electrode positive)

1/8

”

60-90 Amps

5/32

”

90-150 Amps

3/16

”

200-250 Amps

1/4

300-375 Amps*