Operation, Product description, Recommended processes and equipment – Lincoln Electric IM978 POWER MIG 215XT User Manual

Page 14: Welding capability, Limitations, Description of controls

B-2

B-2

OPERATION

PRODUCT DESCRIPTION

The POWER MIG™ 215XT is a complete semiauto-

matic DC voltage arc welding machine built to meet

NEMA specifications. It combines a tapped trans-

former voltage power source with a constant speed

wire feeder to form a reliable robust performance

welding system. A simple control scheme, consisting

of continuous full range wire feed speed control, and 7

output voltage tap selections provides versatility with

ease of use and accuracy. An enhanced feature to the

POWER MIG™ 215XT, is that it is Magnum 100SG

Spool Gun ready.

Other features include a 2" (51 mm) O.D. wire reel

spindle with adjustable brake, an integral gas cylinder

mounting undercarriage, an adjustable Argon blend

flow regulator with cylinder pressure gauge and inlet

hose, a 15 ft. (3.6 m) Magnum 250L GMAW gun and

cable with fixed (flush) nozzle, a 7 ft. (2.1 m) power

cable with plug, and a 10 ft. (3.0 m) work cable with

clamp.

Optional Magnum Spool Gun, Push-Pull Guns and

Adapter kits, Dual Cylinder Mounting kit and

Aluminum Feeding Kit for push feeding with standard

built in feeder are also available.

RECOMMENDED PROCESSES AND

EQUIPMENT

The POWER MIG® 215XT is recommended for GMA

welding processes using 10 to 44 lb (4.5 to 20 kg) 2"

(51 mm) I.D. spools or Readi-Reel

®

coils (with option-

al adapter) of .025" through .045" (0.6 – 1.2 mm) solid

wire, .035" (0.9 mm) stainless, 3/64" (1.2 mm) alu-

minum, .035 (0.9 mm), .045" (1.2 mm) Outershield

®

and .045”(1.2mm) Ultracore

®

as well as .035" (0.9

mm) and .045" (1.2 mm) Innershield

®

self-shielding

electrodes.

The POWER MIG is factory equipped to feed .035"

(0.9 mm) electrodes. It also includes a 200A, 60%

duty cycle (or 250A, 40% duty cycle) rated, 15 ft. (3.6

m) GMAW gun and cable assembly equipped for

these wire sizes. Use of GMAW processes requires a

supply of shielding gas.

WELDING CAPABILITY

The POWER MIG® 215XT is rated at 215 amps @ 22

volts, at a 30% duty cycle based on a ten minute cycle

time. It is capable of higher duty cycles at lower output

currents. The tapped transformer design makes it

well suited for use with most portable or in-plant gen-

erating systems.

LIMITATIONS

The output voltage/current of the POWER MIG®

215XT is subject to vary if the input power to the

machine varies, due to its tapped transformer power

topology. In some cases an adjustment of WFS pre-

set and/or voltage tap selection may be required to

accommodate a significant drift in input power.

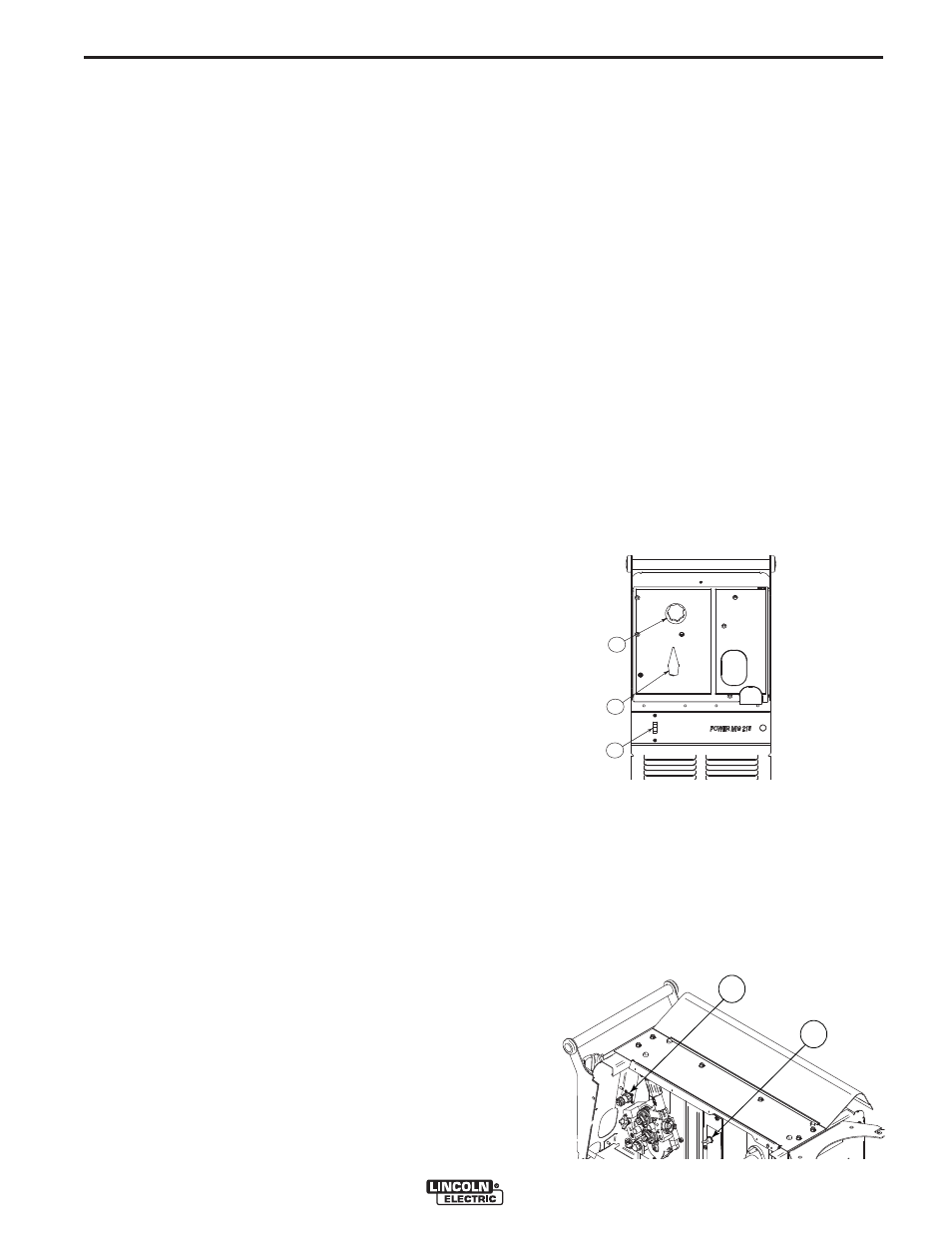

DESCRIPTION OF CONTROLS

See Figure B.1

1. Power ON/OFF Switch — Place the lever in the

"ON" position to energize the POWER MIG®

215XT.

2. Voltage Control — Seven voltage tap selections

are provided Labeled "A" (minimum voltage)

through "G" (maximum voltage). It should only be

adjusted when not welding. The control selection

can be preset to the setting specified on the

Procedure Decal on the inside of the wire compart-

ment door.

3. Wire Speed Control — This controls the wire feed

speed from 50 – 700 inches per minute (1.2 – 17.8

m/min). Wire speed is not affected when changes

are made in the voltage control.

FIGURE B.1

4. Magnum Push Gun and spool gun toggle

switch-Toggle the switch to select between push

gun and spool gun. When spool gun operation is

selected, insert the cable to 4-pin Connector Item

5. (See Figure B.1a)

5. 4-Pin Connector-For Spool Gun Operation.

FIGURE B.1a

3

2

1

4

5

POWER MIG® 215XT