Self-check & fine calibration – Johnson Level & Tool Mfg. 40-6690 User Manual

Page 12

12

©2012 Johnson Level & Tool - Rev. 1

8. Self-Check & Fine Calibration

IMPORTANT: It is the responsibility of the user to verify the calibration of the

instrument before each use.

• Find a road, parking lot, or level plane (slope should be less than 4” at 100’/30m).

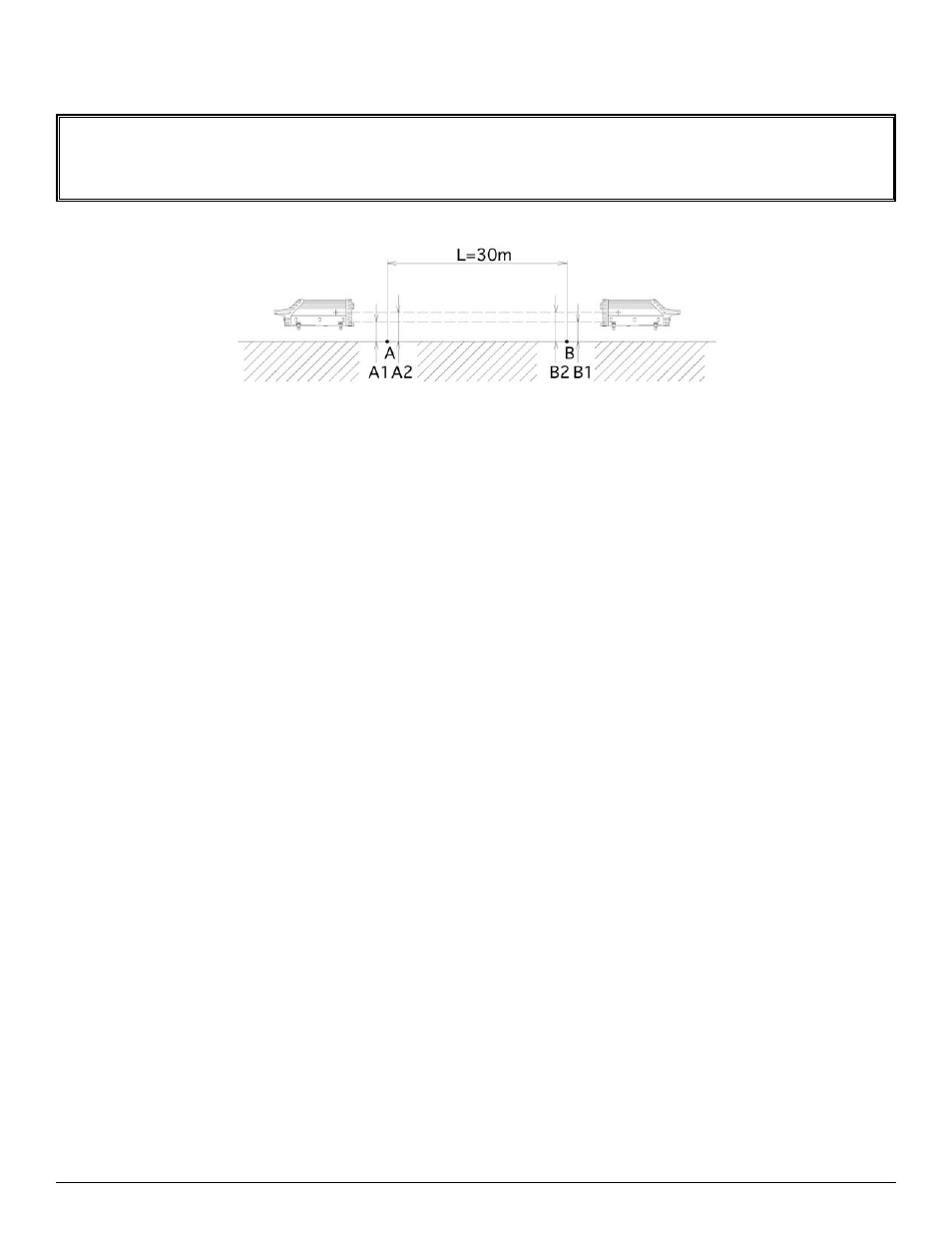

• Pick 2 points (A and B) whose distance is about 100’ or 30m between each other. The

distance does not need to be measured exactly, mark the 2 points.

• Put the pipe laser behind point A, turn it on, and let it warm-up for 10 minutes.

• Set the grade to be 00.000%.

• Point the laser beam to go through points A and B, make sure the laser is in its

self-leveling range.

• Accurately measure the height from the center of the laser beam point A and point B,

note it as A1 and B1.

• Put the laser behind point B and let the laser beam go through points A and B making

sure the laser is in its self-leveling range.

• Accurately measure height from the center of the laser beam to point A and point B,

note it as A2 and B2.

• Calculate A2-A1, B2-B1. If |(A2-A1) - (B2-B1)| is less than or equal to .118” or 3mm,

the accuracy is good;

If the value of A2-A1 is larger than the value of B2-B1, the laser beam is too high,

and the user needs to adjust the laser line to be leveled.

If the value of A2-A1 is smaller than the value of B2- B1, the laser beam is too low,

and the user needs to adjust the laser line to be leveled.