FallTech DuraTech Series SRL’s User Manual

Page 16

31

DuraTech Stainless Cable SRL’s (“S-series”)

Model #s: 7226S, 7227S, 7229S, 7232S, 7267S, 7268S,

7211S, 7212S, 7213S

Component Material

Rating

Housing Cast/Machined

Aluminum Alloy

n/a

Drum

Cast/Machined Aluminum Alloy

n/a

Main Shaft

CNC Machined Aluminum Alloy

n/a

Pawls/Ratchet

Manganese Bronze Alloy

n/a

Pressure Plate

Chro-Moly Alloy Steel

n/a

Cable

3/16” 7 x 19 Stainless Steel

4,000 lbs

Attachment Carabiner

Chro-Moly Alloy Steel

5,000 lbs

Overall static strength:

> 3,000 lbs

* Arrest Forces:

< 800 lbs

* Deceleration Distance:

< 24”

Maximum Capacity:

310 lbs

* When tested in accordance with ANSI Z359.1-2007

DuraTech Stainless Cable SRL’s (“SS-series”)

Model #s: 7226SS, 7227SS, 7232SS, 7266SS, 7268SS, 726575SS

Component Material

Rating

Housing Cast/Machined

Aluminum Alloy

n/a

Drum

Cast/Machined Aluminum Alloy

n/a

Main Shaft

CNC Machined Aluminum Alloy

n/a

Pawls/Ratchet

Manganese Bronze Alloy

n/a

Pressure Plate

Stainless Steel

n/a

Cable

3/16” 7 x 19 Stainless Steel

4,000 lbs

Attachment Carabiner

Stainless Steel

5,000 lbs

Overall static strength:

> 3,000 lbs

* Arrest Forces:

< 800 lbs

* Deceleration Distance:

< 24”

Maximum Capacity:

310 lbs

* When tested in accordance with ANSI Z359.1-2007

DuraTech Heavyweight Cable SRL’s (“HW-series”)

Model #s: 7226HW, 7227HW, 7232HW, 7265HW, 7268HW,

7211S, 7212S, 7213S

Component Material

Rating

Housing Cast/Machined

Aluminum Alloy

n/a

Drum

Cast/Machined Aluminum Alloy

n/a

Main Shaft

CNC Machined Aluminum Alloy

n/a

Pawls/Ratchet

Manganese Bronze Alloy

n/a

Pressure Plate

Chro-Moly Alloy Steel

n/a

Cable

3/16” 7 x 19 Galvanized Steel

4,000 lbs

Attachment Carabiner

Chro-Moly Alloy Steel

5,000 lbs

Overall static strength:

> 3,000 lbs

* Arrest Forces:

< 900 lbs

* Deceleration Distance:

< 30”

Maximum Capacity:

400 lbs

* When tested in accordance with ANSI Z359.1-2007

32

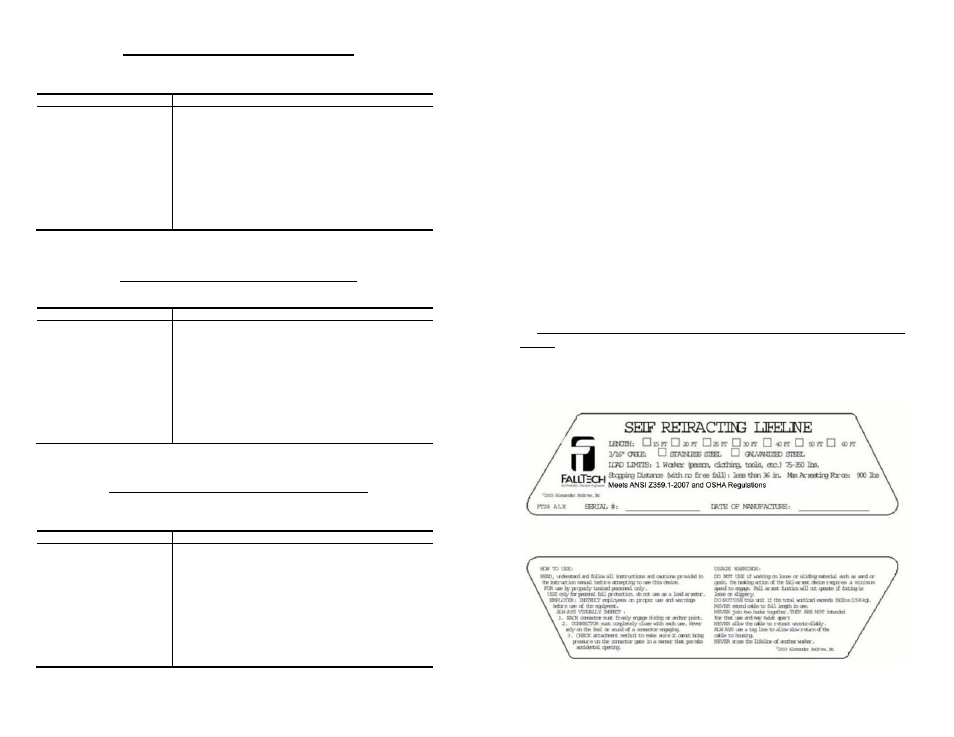

10.3: Labels and Markings

Labels are an important part of the product and should be referred to

often to keep these important details fresh. The labels located on the

front of the housing (shown in figure 10.1) identify the product and

provide key details with respect to the products rating. There is also

information pertaining to the use of the product along with critical

warnings. Failure to heed these warnings may result in serious injury or

death.

The labels on the back of the SRL housing have information

regarding the proper installation and inspection of this product. These

are shown in figure 10.2.

Figure 10.3 is the service label. Be sure to use a permanent marker

to log the date that the product is put into service. This label should be

inspected every six months during the competent person inspection to

ensure that the product is within the recertification parameters discussed

in Section 9 of this manual.

The labels shown below must be present on the product and must be

legible. If they are not, remove the product from service.

Figure 10.1: Located on front housing