Installation procedure, Suction piping for use on deep well injectors, Plumbing of deep well injectors – Davey 165D DEEP WELL PRESSURE PUMPS & SYSTEMS User Manual

Page 4

- 4 -

- 9 -

Installation Procedure

The Deep Well Injector Kit comprises a bronze injector and foot valve

assembly which is attached to the end of polythene piping and lowered

into the water. Deep well injector kits include all appropriate fittings for

connection of pipes to pump.

Suction Piping for use on Deep Well Injectors

All Deep Well Injectors require two pipes to be connected between the pump and

the injector, the larger being the suction pipe and the smaller the pressure pipe.

Pipe sizes are according to the table below (except where special sizes may

be specified for a particular installation - consult your Davey Dealer or Davey

Customer Service Centre).

Deep Well Injector Kit No.

Suction and Pressure Pipe Sizes

22469, 22470, 22471, 22472.

22473, 22474, 22475

1

1

/

2

”and 1

1

/

4

”

22570, 22571, 22572, 22573

2” and 1

1

/

2

”

Polythene piping is recommended. Select the grade of pipe which has a pressure

rating equal to the pump max. pressure and the depth to water. Normally rural

class B polypipe is ample. If higher rating pipe is required, consult your Davey

dealer.

Plumbing of Deep Well Injectors

A minimum submergence of 3m (10 ft.) is required for the injector and foot valve

assembly for correct operation.

When water is pumped out from a borehole it is common for the water level in

the bore to drop. However, there is usually a point at which the bore water level

remains static or constant for a given maximum flow from the bore. This new level

is known as the ‘draw down level’ of the bore. It is necessary to establish this

draw down level and the output capacity of the bore at this level before installing a

pump on the bore.

Once the pump has been installed on the bore, it is necessary to regulate the

flow from the pump to ensure it does not exceed the maximum capacity of the

bore at the draw down level. Refer Automatic Demand Response (ADR) Set Up

Instructions.

The minimum submergence of the injector and foot valve assembly of 3m (10 ft) means

the length of piping required from the top of the bore to injector assembly is equal

to the draw down level plus 3m (10 ft). Furthermore, ensure that at least a 2m (6 ft)

clearance exists between the injector assembly and the bottom of the bore.

With the adjustment screw on the ADR valve adjusted fully out, run the pump

until the bore is pumped down to its ‘draw down’ level, whilst the pump outlet is

allowing water to discharge unimpeded.

Maintain the pump pressure at this level using gate valve.

Screw regulating valve adjustment screw in until pressure starts to rise. Open

gate valve a little further, then readjust regulating valve to maintain required

minimum pressure on gauge When gate valve is fully open and regulating valve

is maintaining operating pressure, adjustment is complete. Your pump will now

resist operating in a loss of prime condition, but also optimise it’s performance at

higher pressures. If pump is allowed to operate below the minimum on the table

below, cavitation will occur which causes excessive pump wear, or prime may be

lost.

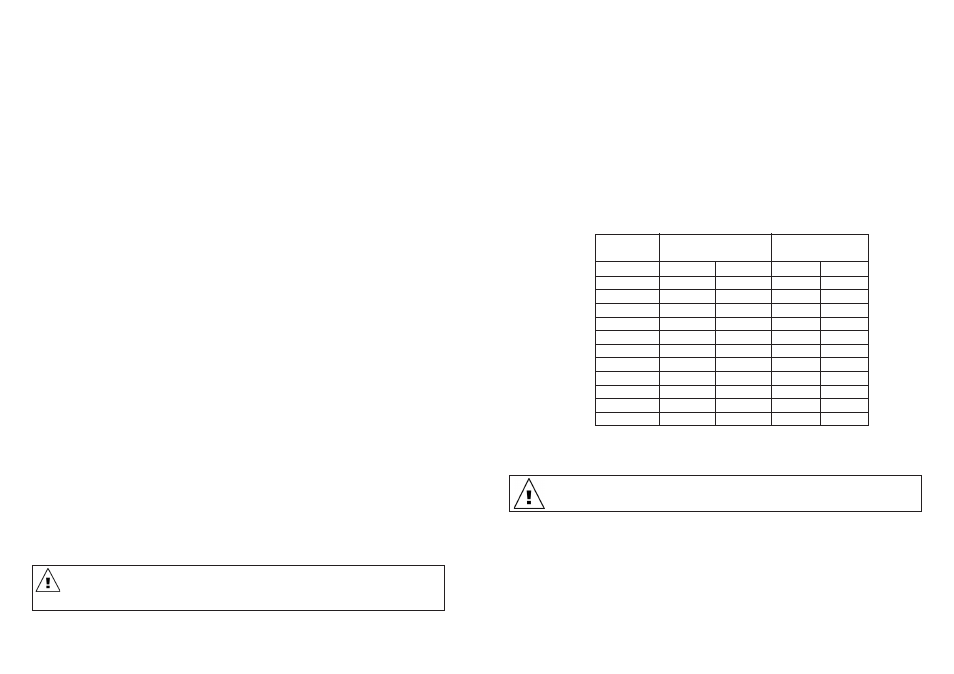

Deep Well Minimum Operating

Max Shut-off

Injector

Pressure

Pressure

Model

kPa

psi

kPa

psi

22469

200

29

550

80

22470

195

28

645

93

22471

220

32

575

83

22472

235

34

660

96

22473

160

23

620

90

22474

240

35

635

92

22475

240

35

750

109

22570

230

33

650

94

22571

170

25

590

86

22572

230

33

630

91

22573

240

35

540

78

Once set there should be no need to alter the setting of the ADR valve, unless

there is a major change with the installation.

To Check for Correct Automatic Pressure System

Operation

1. Close gate valve at pump outlet, allowing pump to run and build up pressure

until it switches off at cut-out setting of pressure switch (factory setting of

350kPa).

2. Open gate valve at pump outlet to allow water to discharge to an outlet point.

Pump will automatically switch on at cut-in setting of pressure switch (factory

setting of 210kPa).

Always operate the pump at or above the minimum operating pressure. Failure to do

so will result in pump damage not covered by guarantee.