Summary of installation procedure, Trouble shooting continued – Davey 165D DEEP WELL PRESSURE PUMPS & SYSTEMS User Manual

Page 2

- 2 -

- 11 -

Prior to using this pump you must ensure that:

• The pump is installed in a safe and dry environment

• The pump enclosure has adequate drainage in the event of leakage

• Any transport plugs are removed

• The pipe-work is correctly sealed and supported

• The pump is primed correctly

• The power supply is correctly connected

• All steps have been taken for safe operation

Appropriate details for all of these items are contained in the following Installation

and Operating Instructions. Read these in their entirety before switching on

this pump. If you are uncertain as to any of these Installation and Operating

Instructions please contact your Davey dealer or the appropriate Davey office as

listed on the back of this document.

Summary of Installation Procedure

For Automatic Operation as a Pressure System with Supercell Pressure Tank

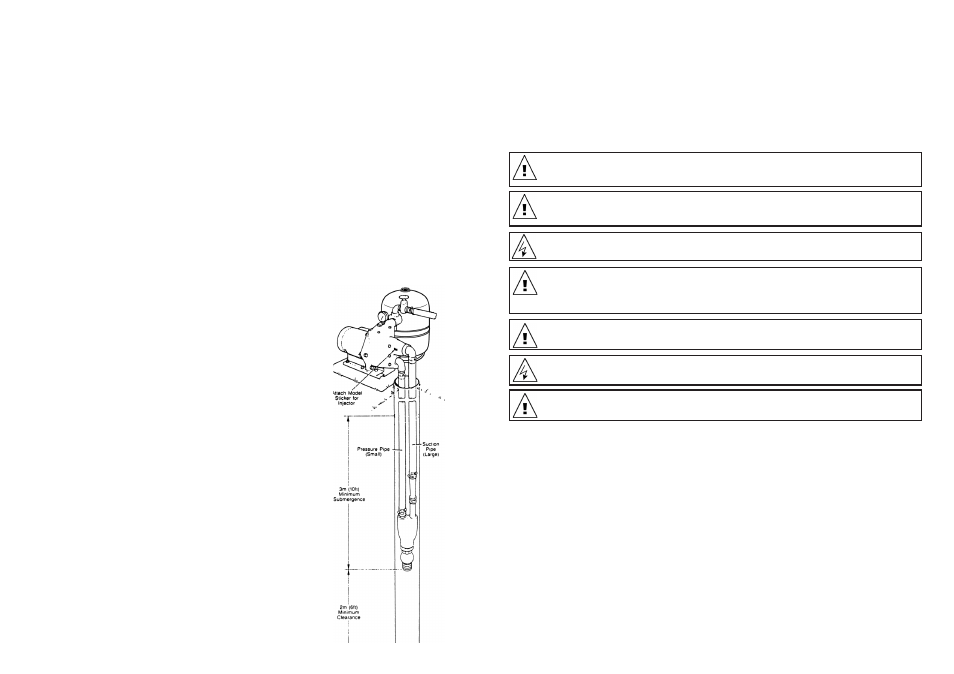

1. Securely bolt pump to wooden, metal or concrete

base, adjacent to bore, as shown in illustration, to

allow suction pipework to be installed directly down

bore. Alternatively, for offset installations, when

pump is not directly adjacent to bore, pump may be

positioned on a firm base without securing.

2. For base mounted tanks place tank next to pump and

connect tank hose to bottom connection of pressure

regulating valve, after removing cap. If using the

Davey Tank connection kit you need only tighten by

hand (no sealant required). Use of pipe wrench is not

required and should be avoided.

For top mounted tanks a Davey three way tee piece is

required (P/No 48638). This is fitted to the priming hole,

and the tank is screwed into the top of the tee.

3. Fit a gate valve to the 1

1

/

4

” BSP outlet at the pressure

regulating valve.

4. Prepare injector, connecting lengths of polythene

pipe of the correct size to the venturi tube and

injector body.

Trouble Shooting continued...

6. Pump Not Switching Off or Taking Too Long to Switch Off

May be caused by one or more of the following:-

a) Voltage supply too low;

b) Blocked jet or venturi;

c) Leak in discharge pipe or fitting, taps etc.;

d) Worn or blocked pump components, impeller, casing etc.;

e) Drop in water level in water supply source.

*NOTE: For protection, the Davey pump motors are fitted with an automatic reset

thermal overload, constant tripping of this overload indicates a problem e.g. low

voltage at pump, excessive temperature (above 50°C) in pump enclosure.

Care should also be taken when servicing or disassembling pump to avoid possible

injury from hot pressurised water. Unplug pump, relieve pressure by opening a tap on

the discharge side of the pump and allow any hot water in the pump to cool before

attempting to dismantle.

WARNING: When servicing or attending pump, always ensure power is switched off and

lead unplugged. Electrical connections should be serviced only by qualified persons.

WARNING: Automatic reset thermal overloads will allow the pump to restart without

warning. Always disconnect the pump motor from the electrical supply before

maintenance or repairs.

IMPORTANT: DO NOT USE petroleum based fluids or solvents (e.g. Oils, Kerosene,

Turpentine, Thinners, etc) on the plastic pump components or seal components.

WARNING: Do not use hydrocarbon based or hydrocarbon propelled sprays around the

electrical components of this pump.

In accordance with AS 3350.2.41 we are obliged to inform you that this pump is not to

be used by children or infirm persons and must not be used as a toy by children.