Where to use check valves and foot valves, Maintenance – Davey HM Series Pressure Systems with Pressure Switch User Manual

Page 5

8

5

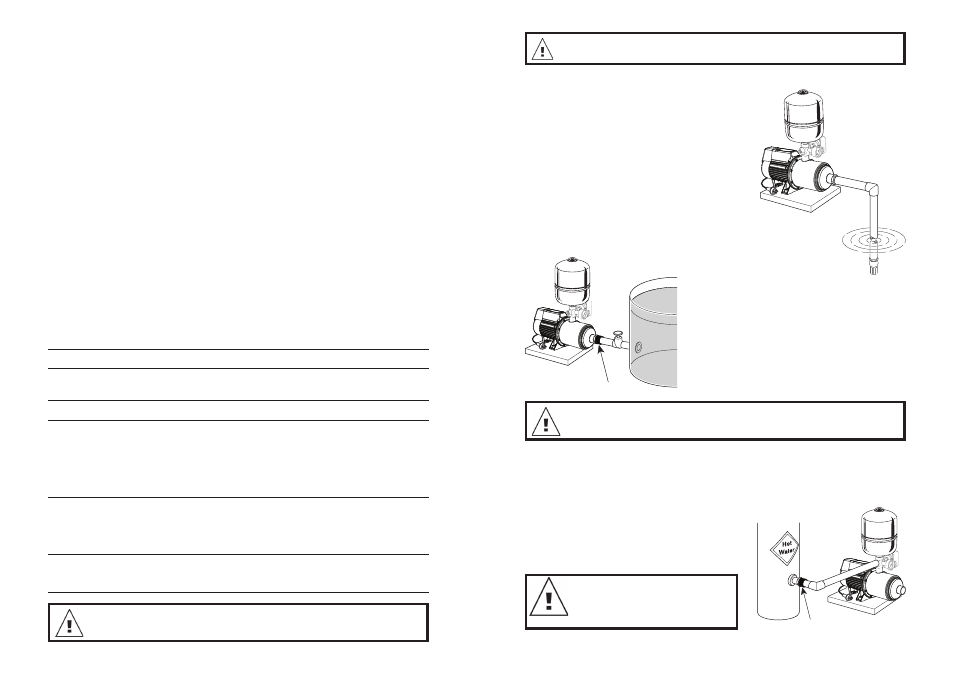

Where to use Check Valves

and Foot Valves

A check valve is required for fitting to

installations with flooded or positive suction.

Care should be taken to ensure that it is

correctly installed in the suction line for

installations with flooded or positive suction.

Installations with flooded suction require a

gate valve so water supply can be turned

off for pump removal and servicing.

On installations with a suction lift a good

quality foot valve with strainer is required.

Installations with flooded suction require

a gate or isolating valve so water supply

can be turned off for pump removal and

servicing.

For Automatic Pressure Pumps Installed with a

Mains Pressure Hot Water System

To protect your system from damage

caused by back pressure from hot water

systems. You should always have installed

on the hot water inlet an approved non-

return valve.

DO NOT USE THREAD SEALING COMPOUNDS, HEMP OR PIPE

DOPE!

MAINS

WA

TE

R

Check valve

Abrasive Materials

The pumping of abrasive materials will cause damage to the pressure

system which will then not be covered by the guarantee.

Approved

non-return valve

NOTE: Always ensure hot

water systems are installed in

compliance with manufacturers

recommendations and in accordance

with all local regulations.

Maintenance

The only regular attention your new pressure system requires is to check

the pressure tank’s air charge every 6 months.

This can be checked at the air valve with a tyre gauge. Do not charge tank

to a higher pressure than 14 kPa below cut-in

pressure setting.

To check air pressure in tank:

1.

Switch off pump.

2.

Open outlet nearest to pump to release water pressure.

3.

Remove air valve cap from top of Supercell tank and charge tank to

correct pressure using air pump and check with tyre gauge.

4.

Switch on.

5.

Close outlet.

NOTE:

Your pump is designed to operate as an automatic pressure system.

The pressure tank will require a specific precharge air pressure dependent

upon model.

While your pressure tank may have been precharged in manufacture,

the precharge pressure should be checked upon installation and every

6 months thereafter. Follow the instructions on the tank. As a guide, the

precharge settings are listed below:-

Pressure Settings

Pump Model

Cut Out

Cut In

Tank

kPa

kPa

kPa

HM270-19P

300

200

180

HM60-06P

HM90-08P

400

250

230

HM160-15P

HM270-25P

HM60-08P

HM90-11P

500

300

280

HM160-19P

HM60-10P

620

350

330

HM90-13P

Note: The above are standard settings which may be adjusted according

to site conditions. Any adjustments should only be made by a suitably

qualified and experienced person.