Electrical power surge protection, Pipe connections, Trouble shooting check list – Davey HM Series Pressure Systems with Pressure Switch User Manual

Page 4

4

9

Electrical Power Surge Protection

An electrical power surge or spike can travel on the supply lines and cause

serious damage to your electrical equipment.

If the installation is subject to electrical power surges or lightning we

strongly recommend the use of suitable additional surge protection devices

on ALL electrical equipment.

In accordance with AS 3350.2.41 we are obliged to inform you that this

pump is not to be used by children or infirm persons and must not be used

as a toy by children.

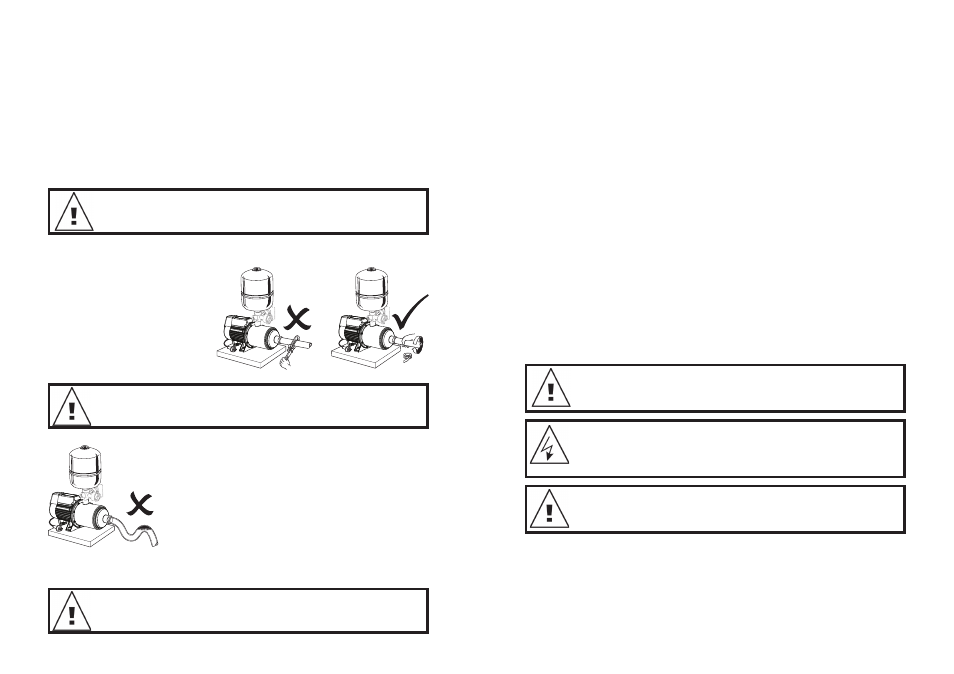

Pipe Connections

For best performance use

P.V.C. or polythene pipes at

least the same diameter as the

pump’s inlet and delivery outlet

openings. Larger diameter

pipe may be used to minimise

resistance to flow when pumping

longer distances.

Use unions at pipe connections to enable easy

removal and servicing. Use sufficient tape to

ensure airtight seal and hand

tighten only. To prevent strain on pump threads

always support heavy inlet and outlet pipes. If

there is a likelihood the water supply

may contain solid particles such as pieces of plant

or vegetable matter, a filter should be installed

before the pump to avoid blocking of water ways. Lay suction pipe at a

constant gradient to avoid air pockets which may reduce pump efficiency.

Do not use pipe thread sealing compounds on any part of this

pump. ONLY use Teflon sealing tape.

NOTE: Suction leaks are the largest cause of poor pump

performance and are difficult to detect. Ensure all connections

are completely sealed using thread tape only.

Trouble Shooting Check List

A) MOTOR RUNS WHEN SWITCHED ON BUT DOES NOT PUMP.

1.

Suction line and pump body not filled with water.

2.

Air leaks in suction lines or suction pipe not under water.

3.

Air trapped in suction lines (also possible with flooded suction due to

uneven rise in piping; eliminate humps and hollows).

4.

No water at source or water level too low.

5.

Valve on suction line closed.

B) PUMP SWITCHES ON AND OFF FREQUENTLY (CYCLING).

1.

Check that tank air pressure is correct.

2.

Leaking taps, float valves etc. Check plumbing.

3.

Leaking check valve/foot valve.

4.

Pressure Switch may require adjustment to cater for flooded suction

installations – consult your Davey dealer for advice.

C) MOTOR DOESN’T START WHEN SWITCHED ON

1.

Power not connected.

2.

Supply voltage too low.

3.

“Over temperature” cut out tripped.*

4.

Motor not free to turn e.g. a jammed impeller.

5.

Internal motor fault.

NOTE: For protection, single phase Davey pump motors are fitted with

an automatic “over temperature” cut-out. Constant tripping of this

overload device indicates a problem e.g. Low voltage at pump, excessive

temperature (above 50°C) in pump enclosure.

Care should also be taken when servicing or disassembling pump to avoid

possible injury from hot pressurised water. Unplug pump, relieve pressure

by opening a tap on the discharge side of the pump and allow any hot

water in the pump to cool before attempting to dismantle.

WARNING: When servicing or attending pump, always ensure power

is switched off and lead unplugged. Electrical connections should be

serviced only by qualified persons. If the electrical supply lead of this

pressure system is damaged, it must only be replaced by authorised Davey

service personnel as special tools are required.

NOTE: For protection, the Davey pump motors are fitted with an automatic

reset thermal overload, constant tripping of this overload indicates a

problem e.g. low voltage at pump, excessive temperature (above 50°C) in

pump enclosure.