Davey RAINBANK WITH SUBMERSIBLE PUMP User Manual

Page 17

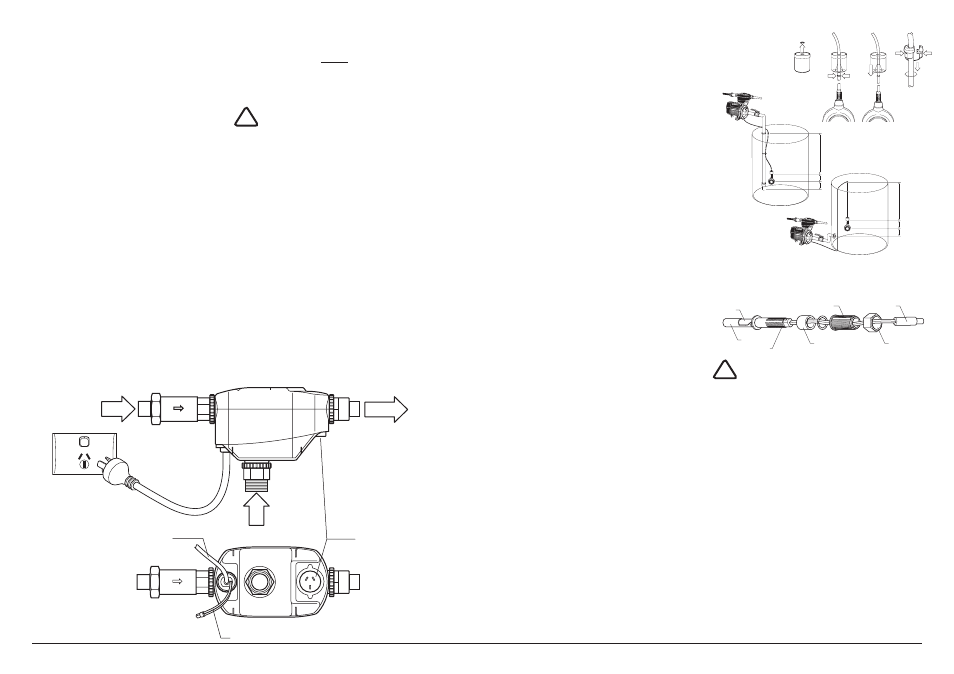

MAINS

WATER

SUPPLY

RAINWATER

SUPPLY

TO TOILETS

AND LAUNDRY

Power to pump via

3 pin socket

5 volt conne ction

for float switch

Incoming power to RainBank®

via 3 pin plug

20

17

• It is highly recommended that an

isolation valve be fitted to where the

mains water enters rainbank

®

and

between the pump and the rainwater

tank. this facilitates easy removal

of the unit if required without turning

off the household water or losing

stored rainwater.

• Do not use thread sealing compounds,

hemp or pipe glue. Do not use

crimped fittings.

• all rainbank plumbing fittings feature

rotating unions that require bracing.

• If your access to the bottom of the

rainbank

®

unit is difficult you may

have to connect the 5 volt connection

from the float switch before the

plumbing is connected.

connect all leads.

STEP 7

1. connect the pump power lead to

the three-pin socket underneath

rainbank

®

.

IMPORTANT

this must connect to the rainbank

®

controller not the power point. If the

pump is connected to the power point

the pump will run constantly,

shortening the life of the pump and

potentially running the pump dry.

2. connect the three-pin power plug from

the rainbank

®

to your power point.

3. connect the 5 volt lead from the float

switch to its flying lead; in the

underside of the unit. this is

not necessary if you are using a

submersible pump as the float switch

is already part of the pump.

!

For greater distances between your

rainwater tank and pump, a 10m float

switch (top and side entry) extension

lead (Davey part no. 14186) will need to

be added. up to 4 float switch extension

leads can be added between the pump

and the rainwater float switch lead. It

is recommended that the float switch

extension lead/s are in a protective cinduit.

STEP 3a - TOP ENTRY FlOAT SWITCH

NOTE: THE VERTICAl POSITION OF

THE FlOAT SWITCH IN RElATION TO

THE PUMP WATER INlET IS CRITCAl

1. Measure the distance from the top of

the tank (a) to the highest point of the

tank outlet to the pump (b).

2. Mark on the float switch cable a length

equal to a-b minus 200 millimeters or

distance (b) to (D).

3. Drill a hole in the top of the tank large

enough to suit a cable grommet or

strain relief grommet (F) - not supplied.

4. snap off retainer clip (c) from top of

weight (D).

5. position retainer clip 100mm from

float ball (e).

6. slide weight (e) over retaining clip and

firmly snap into position.

7. lower weight into tank and feed top of

cable through hole drilled in step 3.

8. Fasten with cable grommet to

previously measured length (a) to (b).

STEP 3b - AlTERNATE SIDE ENTRY

FlOAT SWITCH 32398

IMPORTANT

• the level switch is suitable for

installation in polyethylene and

fibreglass tanks. It can be fitted in

steel tanks but cutting through the

zinc alum or colourbond coating of

the tank exposes bare steel and this

can rust. check with the tank

manufacturer before drilling.

• the float switch is designed to be

installed from the outside of the tank.

there is no need to get inside the tank.

• the sealing grommet of the float

switch is designed to work in a

100

100

100

100

C

D

E

F

A

D

E

B

A

D

E

B

100

100

100

100

C

D

E

F

A

D

E

B

A

D

E

B

100

100

100

100

C

D

E

F

A

D

E

B

A

D

E

B

Top

Bottom

Sealing grommet

Level switch stem

Bayonnet join

Sealing nut

Compression nut

!