Installation housing your pump – Davey VM Series Stainless Steel Vertical Multistage Pumps User Manual

Page 3

3

Altitude & Temperature vs Loss of Head

Altitude

Loss of head

Temperature

Loss of head

0m

0m

20°C

0.20m

500m

0.60m

30°C

0.40m

1000m

1.15m

40°C

0.70m

1500m

1.70m

50°C

1.20m

2000m

2.20m

60°C

1.90m

2500m

2.65m

70°C

3.10m

3000m

3.20m

80°C

4.70m

90°C

7.10m

100°C

10.30m

The pump must be placed in a well drained

location or in a pan connected to a drain to

avoid water damage from leaking fittings,

seals etc.

Hydraulic connections

The diameter of the suction piping must never be less than that

of the pump.

Limit the length of the suction pipe and avoid all features that

cause losses of head (tapers, bends, etc.).

The suction pipe, which should slope upward slightly, must be

fully airtight, especially at fittings.

If a rigid pipe is used, provide supports or collars so that the

pump does not bear the weight of the pipe.

An arrow on the pump casing shows the direction of fluid flow.

Carefully seal the pipes with thread tape.

Electrical connections

continued overleaf...

NOTE: Disconnect pump from power

before undertaking ANY servicing or

clearance checks on the pump.

The electrical connections and checks

must be made by a qualified electrician and

comply with applicable local standards.

WARNING: Some insects, such as small ants,

find electrical devices attractive for various

reasons. If your pump enclosure is susceptible

to insect infestation you should implement a

suitable pest control plan.

Two standard cases for pump installations:

1. Pump in suction lift situation.

2. Pump installed with positive inlet.

Suction Lift: Pumps operate more efficiently with positive

suction. If the pump must be installed with a suction lift,

please ensure the suction line is kept as short as possible and

the pipe diameter is at least on size or larger than the pump

inlet. Suction line should be continuously rising from the water

source to the pump in order to avoid vapour locks.

For suction lift greater than 3 metres or suction distance

greater than 50m please contact Davey.

Positive Inlet: Recommended installation for efficient pumping.

Install the pump in a place that is easy to reach, protected from

frost, and as close as possible to the place from which water is

drawn.

Install the pump on a foundation block at least 100mm high and

attach via the holes for 12mm dia. studs. For heavy pumps,

provide a point of attachment above the pump centre line.

Place an insulating material (cork or reinforced rubber) under

the concrete block to avoid transmitting noise and vibrations to

the rest of the installation. Before final tightening of the anchor

bolts, make sure that the pump centreline is quite vertical; use

shims if necessary.

Motor specifications are typical and should be confirmed at

time of order.

Assembly for pumps supplied without motors fitted

Some Davey VM series multistage pumps require special size

motor bearings built into the motor which may not allow the use

of standard flange mounted motors.

To assemble the motor onto the pump, ensure that the motor

dimensions match the pump head dimensions.

Ensure the motor mounting face and shaft are clean and free

of debris. Lower the motor onto motor adaptor and secure

with four setscrews into the motor flange. Attach the coupling

halves onto the motor shaft and wet end shaft locating the

coupling onto the pump shaft pin. Secure the coupling with

four screws. Hand tighten only on the motor end and somewhat

tighter on the pump end to clamp the pump shaft. Ensure the

pump shaft and coupling will move as one up and down on

the motor shaft. Push coupling down as far as possible and

note it’s position. Raise the coupling up as far as possible and

mark this position. Set the coupling at the midpoint between

the top and bottom positions. Tighten all four coupling screws

evenly (tighten M6 coupling screws to 14Nm or M10 coupling

screws to 36Nm). Rotate the shaft and ensure it is free and

not rubbing. Run the pump for a short period and recheck the

pump still is free to rotate without interference.

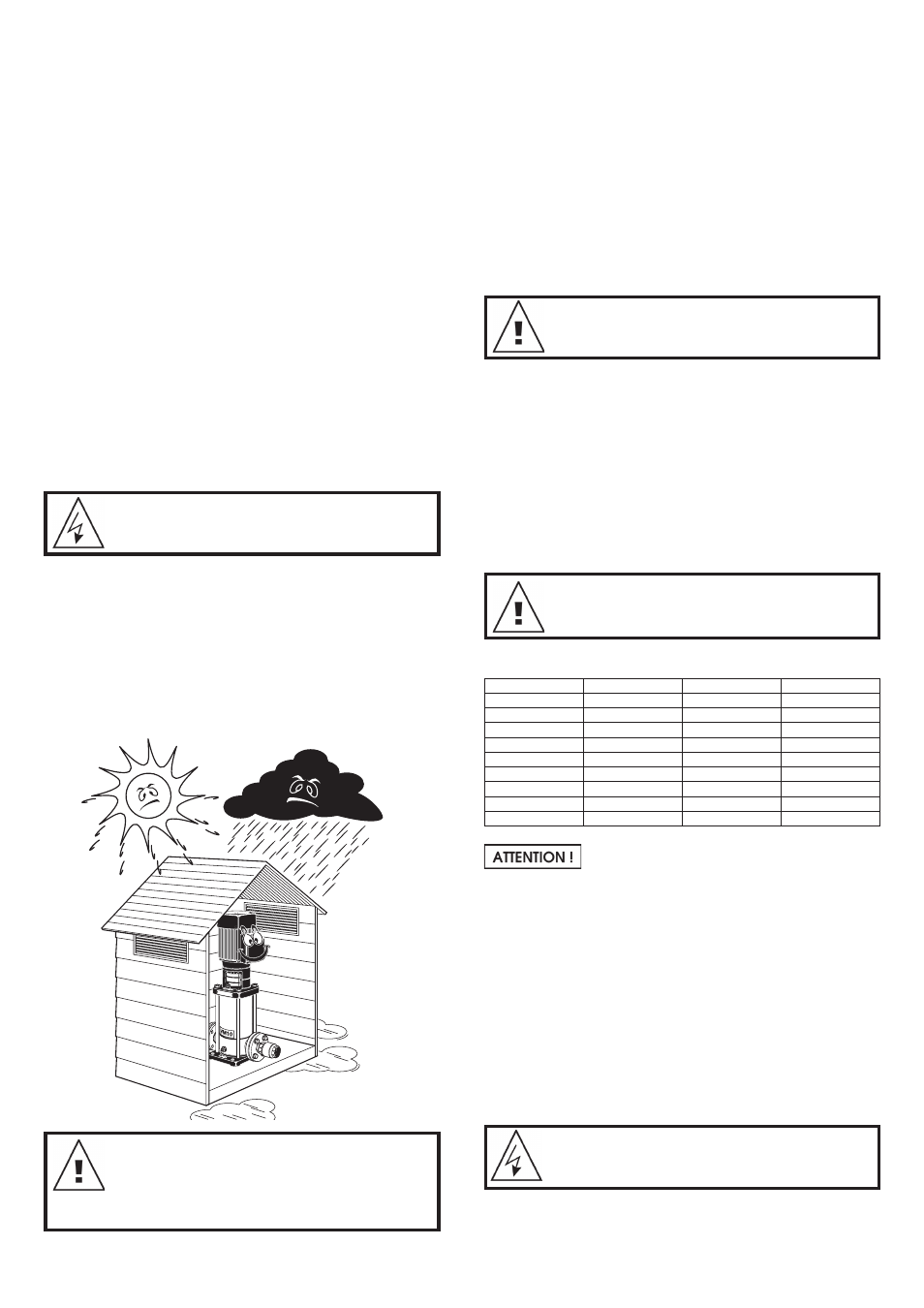

Installation

Housing your Pump

To protect your pump from the weather, make sure the cover

provided is both water proof, frost free and has adequate

ventilation.

The pump should be vertically mounted on a firm dry base

allowing for drainage, to avoid damage to flooring.

Pumping direct from town water supply

must be in compliance with local

regulations.

The altitude of the installation and the

water temperature reduce the suction

capabilities of the pump.