Safety, Transport and storage, Product description – Davey VM Series Stainless Steel Vertical Multistage Pumps User Manual

Page 2: General, Specifications

2

Safety

Read this data sheet carefully before installing and starting

your pump. Pay special attention to the points concerning the

safety of the equipment.

Symbols used in the manual

Calls attention to a potential risk that might

affect safety.

Transport and Storage

When taking delivery of the pump, check that it has not

been damaged in transit. If anything is found wrong, take the

necessary steps with the carrier within the allowed time.

Handle the pump carefully so as not to alter the geometry or

alignment of the hydraulic assembly.

Product Description

The pump

Multistage vertical pump (2 to 20 stages, depending on model).

Not self-priming. Ports in line at bottom. Shaft sealing by

standardized mechanical seal.

• Flanges*

Flanges are round for all models and include screwed

companion flanges with gaskets, nuts, bolts and washers.

* Remove protective inserts from pump ports before fixing

flanges to pump.

The motor

The Davey VM series multi-stage pumps have been specifically

designed to be used with special TEFC flange mounted electric

motors. Typical specification for motors supplied are;

• TEFC motor with standard metric frame flange and shaft for

vertical operation. Motor and pump linked by a coupling with

safety guards.

• Protection index:

IP 54 (min.)

• Insulation class:

F

• Single phase motors up to 2.2kW include built-in thermal

protection with automatic reset, except special dual voltage

(240/480v) motors.

• Dual voltage / larger single phase motors and three phase

motors to be wired in with a contactor incorporating quick-trip

thermal overloads.

NOTE: • Motor sizes 0.37kW to 4.0kW are V18 / B14 small

flange mounted.

• Motor sizes 5.5kW to 22kW are V1 / B5 large

flange mounted, with special bearings.

FREQUENCY

60Hz

SPEED

3600 rpm

VOLTAGE*

1-PHASE

220V

3-PHASE

220/380V

* Standard voltage; tolerance ± 10%

Instructions concerning electricity

If the equipment delivered is to be installed

at a later time, store it in a dry place and

protect it from impact and outside hazards

(moisture, frost, etc.).

WARNING

General

Applications

Pumps for clear liquids, free of abrasives in residential,

agricultural, industrial, and other applications.

Specifications

Operating Conditions

• Temperate range:

-15 to +120°C

• Ambient temperature:

up to 40°C

• Suction head:

depends on NPSH of pump

Maximum Inlet Pressure

The maximum inlet pressure is shown in the list below. But the

actual inlet pressure plus the valve close pressure of the pump

shall be lower than the maximum allowable working pressure.

Model

Max. Inlet Pressure

VM3-8 & above

10 bar

Up to VM5-10

10 bar

VM5-12 & above

15 bar

Up to VM10-6

6 bar

VM10-8 & above

10 bar

VM16-2 and VM16-3

6 bar

VM16-4 & above

10 bar

VM32-2A to VM32-4

4 bar

VM32-6 to VM32-10

10 bar

VM32-12

15 bar

VM65-2A

4 bar

VM65-2 to VM65-3

10 bar

VM65-4A and VM65-5

15 bar

Up to VM90-3A

10 bar

VM90-3 & above

15 bar

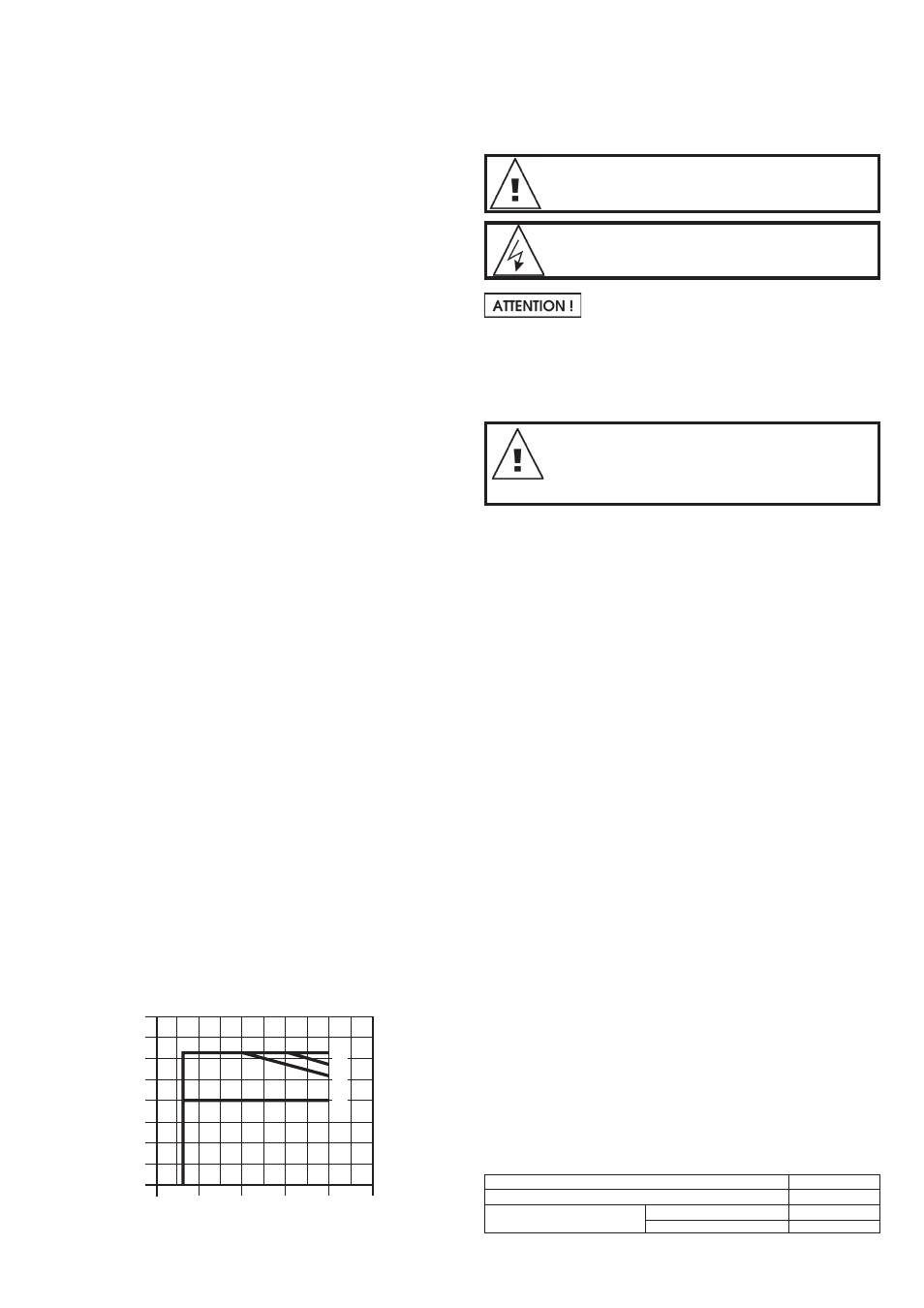

Maximum Working Pressure

Model

Curve Number

Up to VM3-15

1

VM3-17 & above

2

Up to VM5-16

1

VM5-19 and VM5-22

2

VM10-12

1

VM10-14 & above

3

Up to VM16-8

1

VM16-11 & VM16-14

3

Up to VM32-6

1

VM32-8 & above

4

VM65 range

1

VM90 range

1

The following figure shows the limitation of pressure and

temperature, which shall be kept within the region as shown in

the figure.

P(bar)

28

24

20

16

12

8

4

0

-40

0

40

80

120 t(

o

C)

1

2

3

4