Caution, Design considera, Opera – Sterling ERMS User Manual

Page 16: Opera operation tion tion tion tion

4

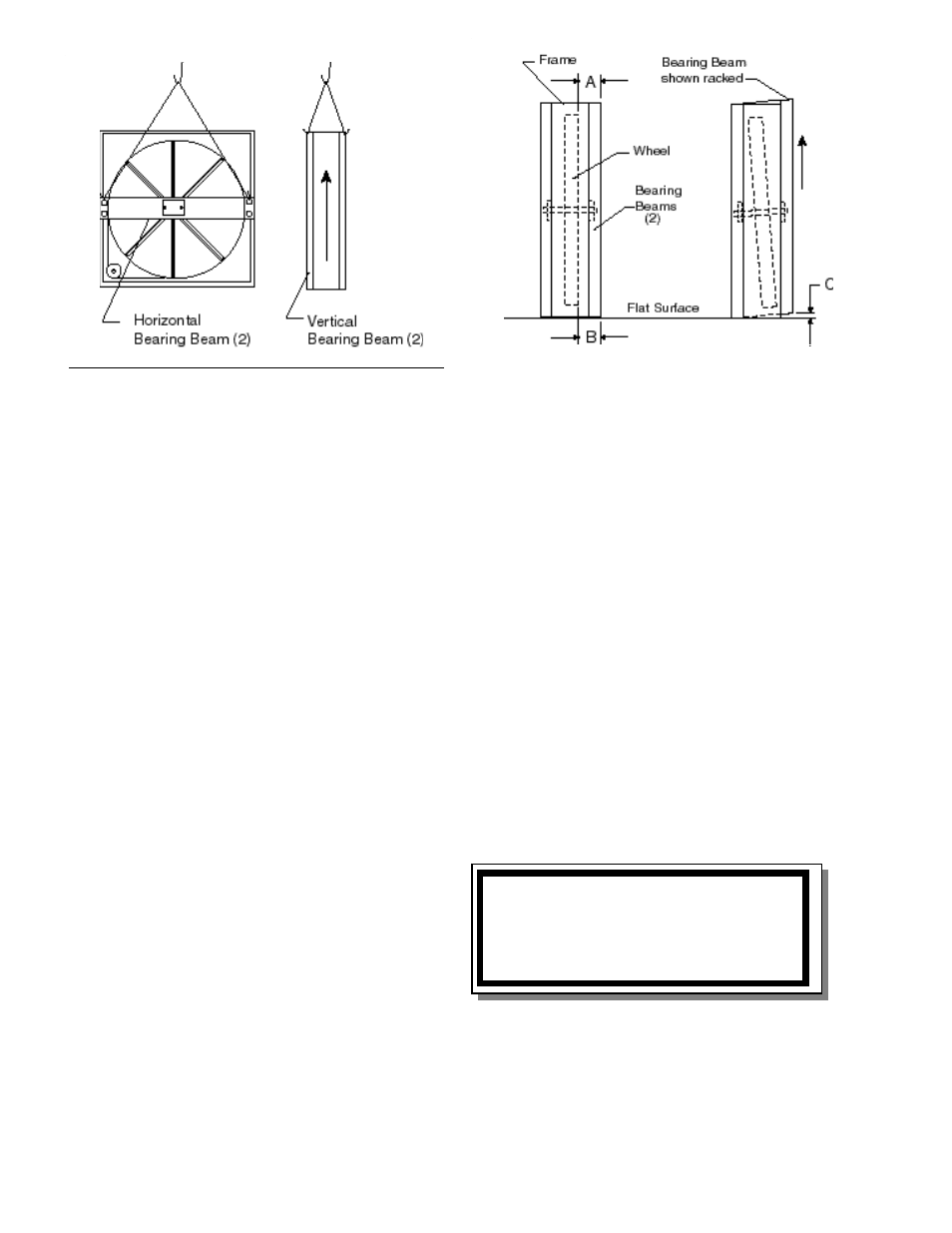

Figure 1 Lifting Hole Locations

Fig ure 2 Av oid Racking of Cassette Frame

CAUTION

Keep hands away from rotating wheel!!

Contact with rotating wheel can cause

physical injury.

DESIGN CONSIDERA

DESIGN CONSIDERA

DESIGN CONSIDERA

DESIGN CONSIDERA

DESIGN CONSIDERATIONS

TIONS

TIONS

TIONS

TIONS

Energy recovery cassettes can be incorporated within

the design of packaged rooftop units, packaged

airhandlers, energy recovery ventilators, or site built air

handling systems. In each case, it is recommended

that the following considerations be addressed

Accessibility

Accessibility

Accessibility

Accessibility

Accessibility

The cassette and all its operative parts; i.e.: motor,

belt, pulley, bearings, seals and energy transfer

segments must be accessible for service and

maintenance. The most practical design to allow

complete access is one in which the cassette can slide

at least half way out of the cabinet or ductwork for

service. This design requires that adequate clearance

be provided outside the enclosure.

Where cassettes are permanently installed in a

cabinet, access to both sides of the cassette must be

provided. Internal partitions that separate air streams

must allow access for bearing removal.

Orientation & Suppor

Orientation & Suppor

Orientation & Suppor

Orientation & Suppor

Orientation & Supporttttt

The Energy Recovery Cassette may be mounted in

any orientation. However, Care m

Care m

Care m

Care m

Care must be taken to

ust be taken to

ust be taken to

ust be taken to

ust be taken to

make cer

make cer

make cer

make cer

make certain that the cassette frame remains flat

tain that the cassette frame remains flat

tain that the cassette frame remains flat

tain that the cassette frame remains flat

tain that the cassette frame remains flat

and the bearing beams are not rac

and the bearing beams are not rac

and the bearing beams are not rac

and the bearing beams are not rac

and the bearing beams are not racked as sho

ked as sho

ked as sho

ked as sho

ked as shown in

wn in

wn in

wn in

wn in

Figure 2.

Figure 2.

Figure 2.

Figure 2.

Figure 2. To verify, make certain that the distance

between wheel rim and bearing beam is the same at

each end of the bearing beam, to within 1/4 of an inch

(dimension A & B, Fig. 2). This amount of racking can

be compensated for by adjusting the diameter seals

(see Fig. 3). If greater than 1/4 inc

If greater than 1/4 inc

If greater than 1/4 inc

If greater than 1/4 inc

If greater than 1/4 inch,

h,

h,

h,

h, rac

rac

rac

rac

racking m

king m

king m

king m

king must

ust

ust

ust

ust

be corrected to ensure that drive belt will not

be corrected to ensure that drive belt will not

be corrected to ensure that drive belt will not

be corrected to ensure that drive belt will not

be corrected to ensure that drive belt will not

disenga

disenga

disenga

disenga

disengag

g

g

g

ge fr

e fr

e fr

e fr

e from wheel.

om wheel.

om wheel.

om wheel.

om wheel.

Note: Bearing beam racking of as little as .040 inches

(Dim C, Fig. 2) will cause the wheel to tilt 3/16” at the

rim.

Diameter Seals

Diameter Seals

Diameter Seals

Diameter Seals

Diameter Seals

Diameter seals are adjusted at the factory when the

wheel is in the vertical position. Cassettes installed at

angles greater than 30 degrees from vertical will

require seal re-adjustment (see page 6, Figure 3).

Adjust diameter seals so as to avoid excessive wheel

drag. A final check of seal adjustment is

recommended for all designs.

Wheel Drive Motor

Wheel Drive Motor

Wheel Drive Motor

Wheel Drive Motor

Wheel Drive Motor

Cassette series 36 through 52 are provided with single

phase wheel drive motors (capacitor included). Single

phase motors may be pre-wired in the factory with

either a three pin Amp connector or three prong

NEMA plug. The motor is designed to rotate clockwise

when viewed from the shaft/pulley side.

Three phase wheel drive motors are provided with

optional 208/230V or 460/480V wiring. Motors may be

pre-wired in the factory upon request. Wiring

diagrams are provided with each motor. When wired

according to wiring diagram, motor rotates clockwise

when viewed from the shaft/pulley side.

OPERA

OPERA

OPERA

OPERA

OPERATION

TION

TION

TION

TION

Star

Star

Star

Star

Start Up Pr

t Up Pr

t Up Pr

t Up Pr

t Up Procedure

ocedure

ocedure

ocedure

ocedure

1.

By hand, turn wheel clockwise (as viewed from

the pulley side), to verify wheel turns freely

through 360º rotation.

2.

Before applying power to drive motor, confirm

wheel segments are fully engaged in wheel

Page 14 of 26

Page 16 of 28