Recommended oil supply systems, Wiring, 2 pipe system – Sterling QVOF User Manual

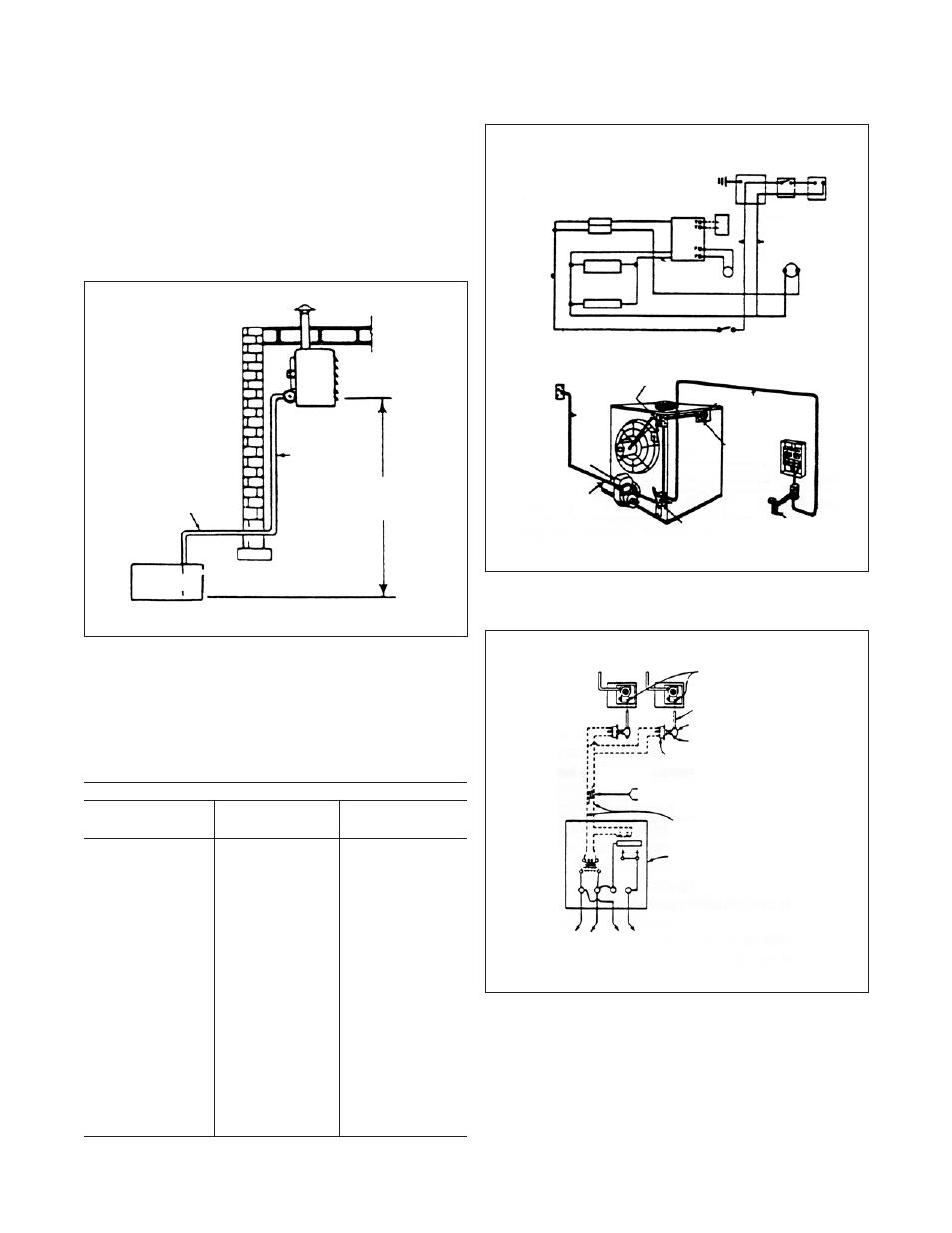

Page 6: Figure 7 figure 8 - intermittent operation

6

RECOMMENDED

OIL SUPPLY SYSTEMS

2 PIPE SYSTEM

Separated suction oil line must be used for second unit.

Return oil lines can be twinned together.

Correct line size for two pipe installation 1/2″ O.D. tubing.

Figure 6

Maximum allowable length of either intake or return line

in feet, including horizontal and vertical run.

Maximum line lengths shown above are calculated for

No. 2 oil at 60° and 3450 RPM pump speed.

Table A

“Lift” Installation Values

Distance “B”

Single

Two

Lift

Stage

Stage

0′

100′

100′

1′

100′

100′

2′

100′

100′

3′

100′

100′

4′

100′

100′

5′

100′

100′

6′

100′

100′

7′

99′

100′

8′

83′

100′

9′

68′

100′

10′

52′

100′

11′

42′

100′

12′

25′

100′

13′

—

100′

14′

—

100′

15′

—

100′

WIRING

Figure 7

Figure 8 - Intermittent Operation

RETURN LINE

B

SEE TABLE A

SUCTION LINE

OIL TANK

JUNCTION BOX

FUSER 9A

ENTRANCE

9A CM

LINE

FAN

BLACK

PRIMARY

CONTACT

THERMOSTAT

BLACK

BLACK

WHITE

BURNER

MOTOR

ORANGE

BLUE

WHITE

BURNER SERVICE

SWITCH

CAD

CELL

BLOWER

MOTOR

THERMOSTAT

TOGGLE

SWITCH

JUMPER

IN PLACE

WIRING

CABLE

FAN SIDE

LIMIT SIDE

TYPICAL

ENTRANCE

SWITCH

COMBINATION

CONTROL

TWO WIRE

CABLE

PRIMARY

CONTROL

AND IGNITION

TRANSFORMER

TO THERMOSTAT

TERMINALS ON

PRIMARY CONTROL

JUNCTION BOX

TYPICAL

FUSED SWITCH

CONNECT PRESSURE

SWITCH TO FUEL UNIT

GAGE PORT

1/8 NIPPLE OF LENGTH TO

CLEAR STRAINER COVER

1/8 TEE

1/8 PIPE PLUG

PRESSURE SWITCH

NORMALLY OPEN

MANUAL

BOOST PUMP

SWITCH

CLOSED –

OPEN –

CONTINUOUS OPERATION

OPERATES ONLY UPON

BURNER DEMAND

LOW VOLTAGE

TWO CONDUCTOR WIRE

SWITCH RELAY

LINE

VOLTAGE

POWER

SUPPLY

TO BOOST

PUMP

MOTOR