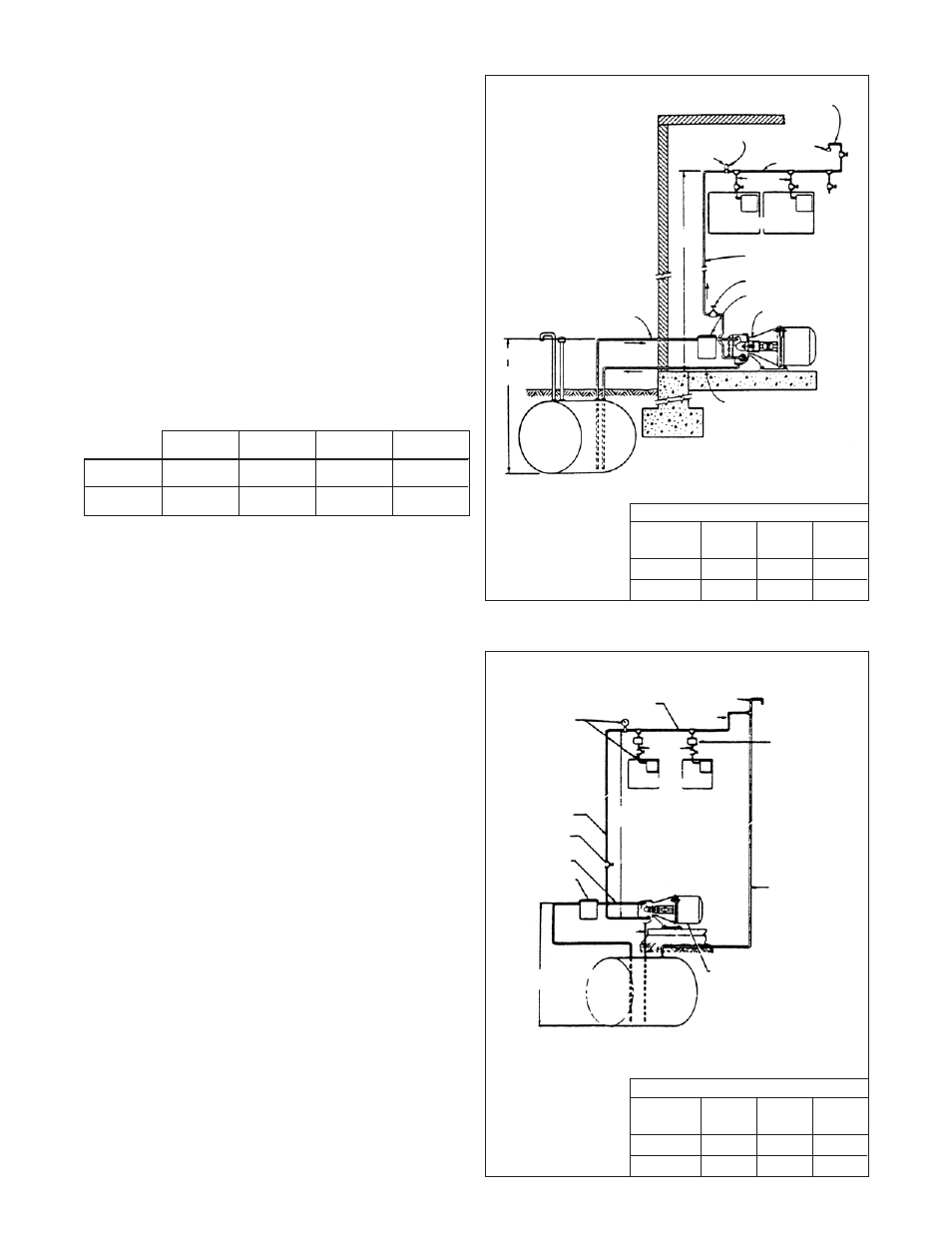

Recommended oil supply systems, Booster pump, Figure 5 - loop system – Sterling QVOF User Manual

Page 5

5

RECOMMENDED

OIL SUPPLY SYSTEMS

BOOSTER PUMP

SETTING PRESSURE AND BLEEDING

FIGURES 4 AND 5

1. Stop all burner pumps.

2. Start boost pump manually

3. Set boost pump pressure so that gauge in first burner

manifold reads not more than 10 P.S.I.

4. Bleed air from first burner pump by loosening unused

inlet plug; bleed other units downstream the same

way.

5. Bleed manifold by loosening pipe cap (Figure 4).

6. For automatic operation, place switch on OFF.

Boost Pump Maximum Inlet Line (Ft.)

For Figures 4 & 5

Operation is extremely simple. Pressure developed by

oil burner fuel unit closes low-voltage switch connected

to it. This causes switch relay to energize boost pump

motor, which starts and stop automatically with burner.

For initial start-up, switch relay may be held “in”

manually. Or a manual ON/OFF switch can be

connected across low-voltage wires leading from switch

relay to pressure switch. With manual switch in “ON”

position, boost pump runs continuously.

NOTE: Check all burners for normal start and fuel

units for stable atomizing pressure. Then open boost

pump switch for automatic operation upon burner

demand.

Systems in Figures 4 and 5 will be in constant operation

when low-voltage switches are not used.

NOTE: Installations in figures 4 and 5 can be either

Intermittent or Constant operation.

CAUTION: When 2′ riser cannot be maintained, use

pressurized system in Figure 4.

Manifold and feeder lines must be run in a horizontal

plane and elevated above fuel unit intakes. At furnace

locations, extend feeder lines downward to fuel unit

intakes.

Install in accordance with National Board of Fire

Underwriters and local ordinances where applicable.

Figure 4 - Pressurized System

Boost

1/2″

1/2″

3/4″

Pump

Tube

Pipe

Pipe

30 GPH

300′

800′

2500′

50 GPH

175′

350′

1500′

Maximum Horizontal Line

Figure 5 - Loop System

Boost

1/2″

1/2″

3/4″

Pump

Tube

Pipe

Pipe

30 GPH

300′

800′

2500′

50 GPH

175′

350′

1500′

Maximum Horizontal Line

Height

0-7′

10′

13′

15′

30 GPH

100′

80′

63′

52′

50 GPH

60′

53′

41′

34′

MANIFOLD AIR BLEED – HIGHEST POINT IN LINE

MAX INTAKE PRESSURE

AT BURNER 6 PSI

PIPE CAP

COMPOUND

GAUGE

MANIFOLD LINE

FEEDER

LINES

NO. 1

NO. 2

SUSPENDED FURNACES

FURNACE

NO. 3 ETC.

35 FT.

MAX

1/2" O.D. TUBING

1/2" O.D. TUBING

1/2" O.D. TUBING – INTAKE LINE

SHUT OFF VALVE

AUXILIARY FILTER

BOOST PUMP

AND MOTOR SET

TANK

"h"

15 FT.

MAX

MAX INTAKE GAUGE

PRESSURE AT FIRST

BURNER 6 PSI

MANIFOLD LINE

VENT

RISER

FEEDER

LINES

NO. 1

NO. 1

SUSPENDED FURNACES

OIL

SAFETY VALVES

35 FT.

MAX

1/2" O.D. TUBING

SHUTOFF VALVE

INLET

1/2" O.D. TUBING

AUXILIARY FILTER

1 1/4" PIPE

RETURN 1/2" O.D. TUBING

BOOST PUMP ASSEMBLY

TANK

15 FT.

MAX LIFT