Sterling TD User Manual

Page 2

2

VENTING FOR POWER VENTED DUCT FURNACES (CATEGORY III)

GENERAL GUIDELINES

All duct furnaces must be vented! All venting installations shall be in accordance with the latest edition of Part

7, Venting of Equipment of the National Fuel Gas Code, ANSI Z223.1 (NFPA 54), or applicable provisions of local

building codes for power vented units. Refer to Figures 3a, 3b, 4a, 4b, 5a, and 5b. For installations in Canada, see

page 3.

CARBON MONOXIDE! Your venting system must not be blocked by any snow, snow drifts, or

any foreign matter. Inspect your venting system to ensure adequate ventilation exists at all times! Failure to

heed these warnings could result in Carbon Monoxide Poisoning (symptoms include grogginess, lethargy,

inappropriate tiredness, or fl u-like symptoms).

NOTICE: All vertical and horizontal venting arrange-

ments for the Tubular Duct Furnace are Category III

venting.

ANSI now organizes vented appliances into four

categories.

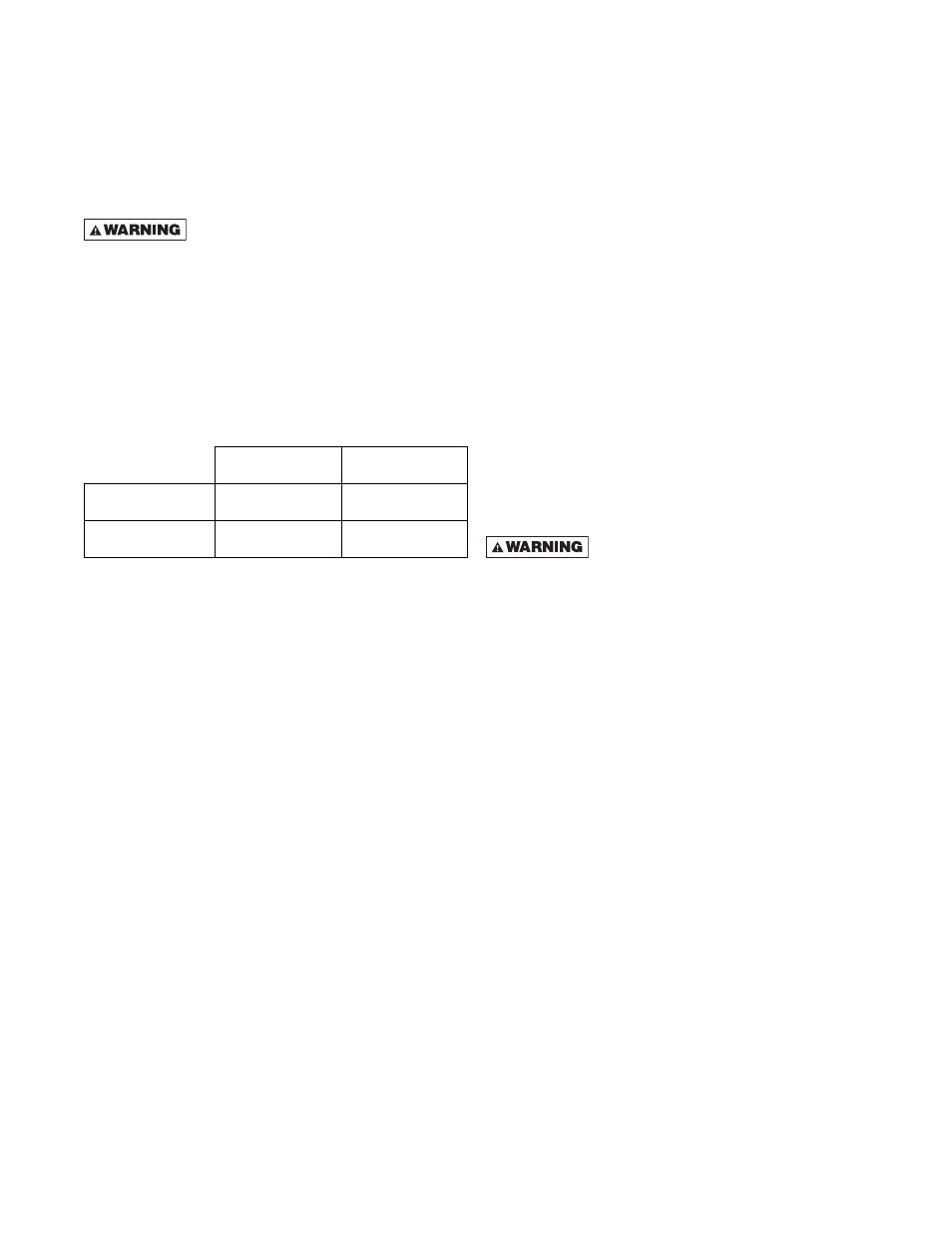

Venting Categories

Non

Condensing

Condensing

Negative

Vent Pressure

I

II

Positive

Vent Pressure

III

IV

Category I

Includes non-condensing appliances with negative vent

pressure, like the traditional atmospheric unit heater.

Category II

Groups condensing appliances with negative vent

pressure.

Category III

Appliances are non-condensing and operate with a

positive vent pressure.

Category IV

Covers condensing appliances with positive vent

pressure.

Do not damper or add heat recovery devices to the fl ue

piping. Failure to open such a damper prior to operating

gas unit will result in the spillage of fl ue gas into the

occupied space.

Vent pipe material must be in compliance with UL 1738

for installations in the United States, and UL S636 for

installations in Canada.

Refer to Table 1 for vent termination clearance

requirements.

Through the wall vents for these appliances shall NOT

terminate over public walkways, or over an area where

condensate or vapor could create a nuisance or hazard

or could be detrimental to the operation of regulators,

relief valves, or other equipment.

The vent pipe equivalent length must be 5 feet (1.5m)

minimum and must not exceed 50 feet (15.2m).

Equivalent length is the total length of straight

sections PLUS 10 feet (3.05m) for each 90 degree

elbow, and 4 feet (1.22M) for each 45 degree elbow.

Maintain 6 inch (152mm) between vent pipe and

combustible materials. A minimum of 12 inch (305mm)

of straight pipe is required from the venter outlet before

installing an elbow in the vent system. An elbow should

never be attached directly to the venter!

Never use a pipe of a diameter other

than that specifi ed in Table 1! Never use PVC or other

nonmetallic pipe for venting! To do so may result in

serious damage to the unit, severe personal injury,

or death.

Any run of single wall vent pipe exposed to cold air or

passing through an unheated space must be insulated

with insulation suitable to 550°F (288°C).

The vent system must be installed to prevent collection

of condensate. Vertical vent pipes should be equipped

with condensate drains. Pitch horizontal pipes down-

ward 1/4 inch per foot (21mm/m) toward outlet for

condensate drainage.

Horizontal portions of the venting system shall be

supported at maximum intervals of 4 feet (1.2m) to

prevent sagging. In Canada, support at a maximum

of 3 feet (1m) intervals.

Each unit must have an individual vent pipe and

vent terminal per furnace section! Each unit MUST

NOT be connected to other vent systems or to a

chimney.