Installation locations, External wiring, Maintenance – Yokogawa JUXTA VJT6 User Manual

Page 2: Rjc sensor, Warning, Important, 1 calibration apparatus, 2 calibration procedure

2

IM 77J01T06-01E

4th Edition

Feb. 09,2007-00

5. INSTALLATION LOCATIONS

●

Avoid the following environments for installation locations:

Areas with vibration, corrosive gases, dust, water, oil, solvents, di-

rect sunlight, radiation, a strong electric field, and/or a strong

magnetic field

●

If there is any risk of a surge being induced into the power line

and/or signal lines due to lightning or other factors, a dedicated

lightning arrester should be used as protection for both this unit

and a field-installed device.

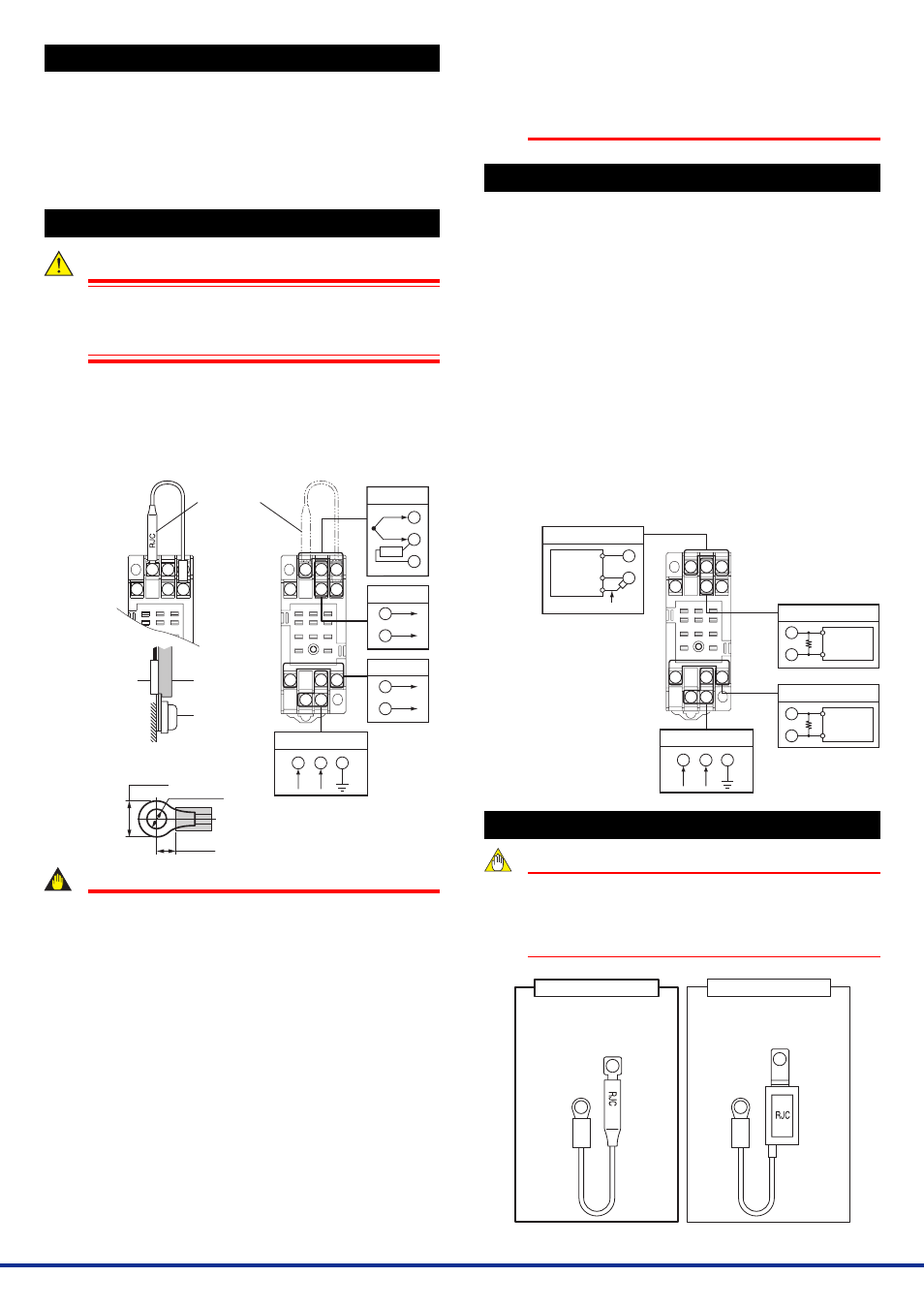

6. EXTERNAL WIRING

WARNING

To avoid the risk of an electric shock, turn off the power

supply and use a tester or similar device to ensure that no

power is supplied to a cable to be connected, before carring

out wiring work.

Wiring should be connected to the terminals on the socket of the prod-

uct. The terminals for external connections are of M3 screws. Use

crimp-on terminal lugs for connections to the terminals.

●

Recommended cables: A nominal cross-sectional area of 0.5 mm

2

or thicker for signal cables, and that of 1.25 mm

2

or thicker for

power cables.

10

11

3

2

1

4

5

6

7

8

9

Signal

line

RJC

sensor

Terminal

screw

10

11

3

2

1

4

5

6

7

8

9

11

10

8

L+

N–

GND

7

9

+

–

2

1

3

4

5

+

–

+

–

RJC

Power supply

RJC sensor

(A1167HT)

Output-2

Input signal

Output-1

Recommended crimp-on lug

size (Unit: mm)

5.5 or less

5.5 or more

ø3.2 to 3.5

IMPORTANT

●

Connect the RJC sensor at the correct position as shown

above. Otherwise temperatures cannot be measured

correctly.

●

Connect the RJC sensor so that it overlaps the input

signal line.

●

Handle the RJC sensor lead wire with care to prevent

disconnection.

●

The power line and input/output signal lines should be

installed away from noise-generating sources. Other

wise accuracy cannot be guaranteed.

●

The grounding resistance must be 100

Ω

(JIS Class D

grounding). The length and thickness of the grounding

cable should be as short and thick as possible. Directly

connect the lead from the ground terminal (terminal no.

8) of the product to the ground. Do not carry out daisy-

chained inter-ground terminal wiring.

●

Use of the product ignoring the specifications may cause

overheating or damage. Before turning on the power, en-

sure the following:

(a)Power supply voltage and input signal value applied to the

product should meet the required specifications.

(b)The external wiring to the terminals and wiring toground

are as specifications.

●

Do not operate the product in the presence of flammable

or explosive gases or vapors. To do so is highly danger-

ous.

●

The product is sensitive to static electricity; exercise

care in operating it. Before you operate the product,

touch a nearby metal part to discharge static electricity.

7. MAINTENANCE

The product starts running immediately when the power is turned on;

however, it needs 10 to 15 minutes of warm-up before it meets the

specified performance.

7.1

Calibration Apparatus

●

Calibrator (Yokogawa Meters & Instruments‘ CA71 or equivalent): 1

●

Temperature sensor (Yokogawa Meters & Instruments‘ B9108WA

or equivalent): 1

●

Digital multimater (Yokogawa 7561 or equivalent): 1

●

Precision resistor of 250

⍀

±

0.01%, 1 W

7.2

Calibration Procedure

(1) Connect the instruments as shown below. First adjust the output-1

signal and then the output-2 signal.

(2) Use the calibrator and apply input signals equivalent to 0, 25, 50,

75, and 100% of the input span to the product. Check to see the

corresponding output voltages are 0, 25, 50, 75, and 100% re-

spectively and within the specified accuracy rating. “R” is used for

current output.

●

If the output signals are out of the accuracy rating range, adjust

the output signal level using the zero and span adjustment vol-

umes on front face of the product.

10

11

3

2

1

4

5

6

7

8

9

11

10

8

Temperature sensor (B9108WA)

1

3

–

+

2

5

R

Ϫ

ϩ

7

9

R

Calibrator

R: 250

⍀

precision resistor

for current output

Power supply

Output-2

Input

Output-1

L

ϩ

N

Ϫ

GND

Digital

multimater

Ϫ

ϩ

Digital

multimater

8. RJC Sensor

NOTE

The product works normally when the RJC sensor

“A1167HT” (see the figures below) is connected to the

socket. If another RJC sensor is connected, it does not

work normally. Make sure that the correct RJC sensor is

connected referring to the figures below.

The RJC sensor for the product

(For the VJT6 with style of 3.00

or higher)

The RJC sensor for the VJT6 with

former style

“Not available for the VJT6 with

style of 3.00 or higher”

Part number: A1167HT

Part number: E9786WA

The style of VJT6 is indicated on the nameplate attached to the

side face of the main unit.