English – Pfister 0X8-310A User Manual

Page 4

9

10

12

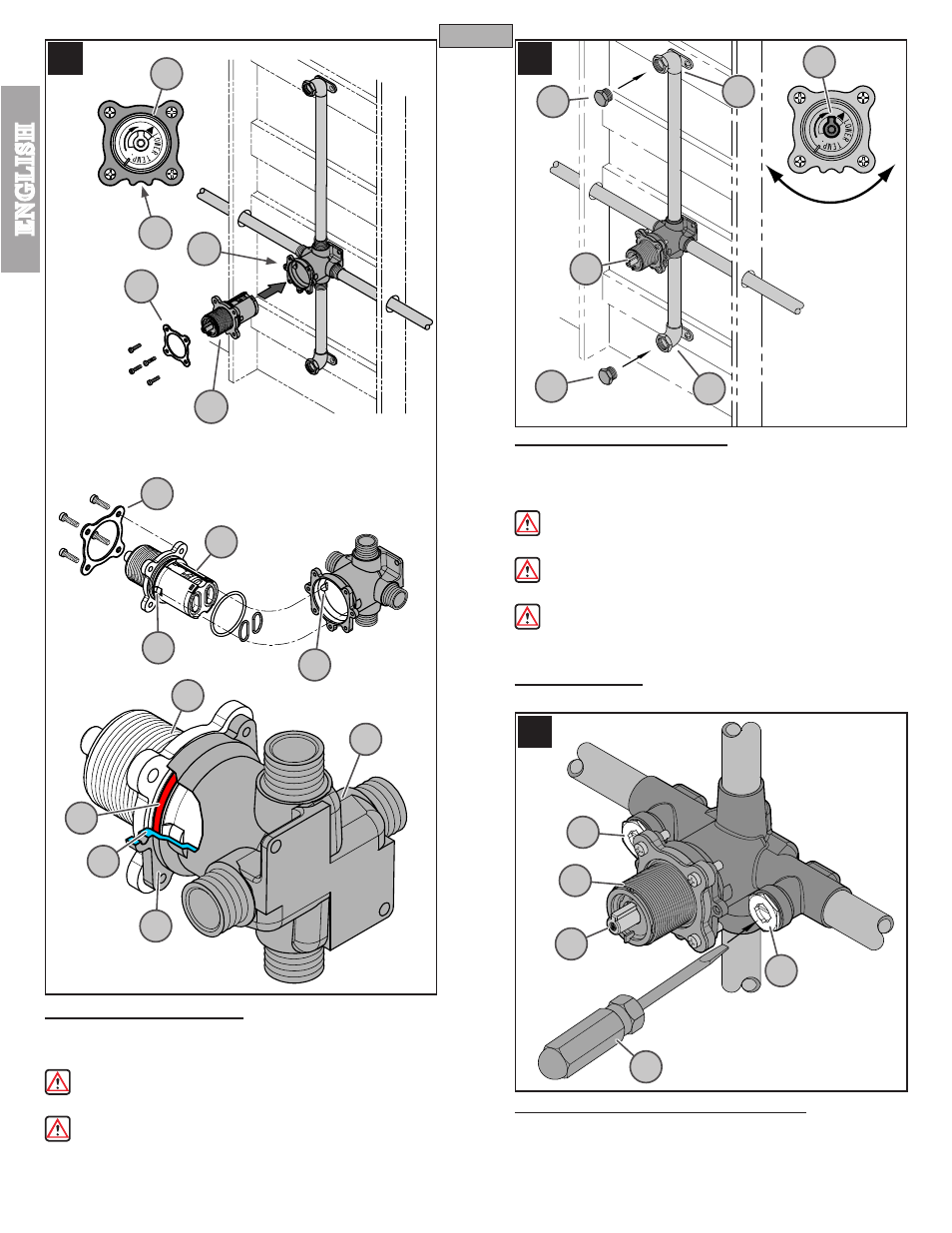

9 CARTRIDGE REASSEMBLY

Once all pipe joints are soldered, reassemble the Cartridge Assembly (9A)

and Backup Plate (9B) into Valve Body (9C). Be sure that Notch (9D) from

the Bonnet (9E) is pointing down (For back-to-back installation see step 20).

WARNING: When reassembling unit, be sure that Tabs (9F) from the

Cartridge Assembly (9A) are set properly on the Valve Body groves (9G).

WARNING: When reassembling the Cartridge Assembly (9A) and Backup

Plate (9B), be certain that the placement of the O-ring (9H) is within the groove

and not pinched between the backup flange (9G) and casting wall (9J). Failure

to do so will result in water leaks and water damage.

10 PRESSURE TESTING VALVE

Use two

1

/

2

" iron pipe plugs (10A) (not included) on both Shower Outlet (10B)

and Tub Outlet (10C). Turn Stem (10D) counterclockwise to full on position

and check all connections for leaks. Rotate Stem (10D) clockwise to turn off.

Look for leaks from the outlets.

WARNING: Pressure testing is not to exceed 250 PSI. Make sure

pressure is balanced between hot and cold inlets.

WARNING: Differential pressure of hot and cold inlets must not exceed

100 PSI.

CAUTION: Slowly remove pipe plugs (10A) from tub and shower outlets

to relieve pressure.

11 UNIT START UP

Turn on water supplies, and check all connections for leaks.

12 MODEL WITH INTEGRAL VALVE STOPS

Integral Stops (12A) provide an alternate means to shut off the water supply. With

a flat head screwdriver (12B), the entire water supply can be shut off by rotating

the valve stem (12C) clockwise. The integral stops can be used for temporary

shutting off the water supply to allow access to the cartridge assembly (12D) for

maintenance.

4

ENGLISH

ENGLISH

9D

9B

9A

9C

9A

9E

9G

9F

9A

9B

9H

9G

9J

ON

OFF

10A

10A

10C

10B

10D

10D

12A

12A

12B

12C

12D

9C