Materials of construction continued, Materials – Versa-Matic Versa-Surge Surge Suppressors for Air-Driven Diaphragm Pumps Metallic User Manual

Page 5

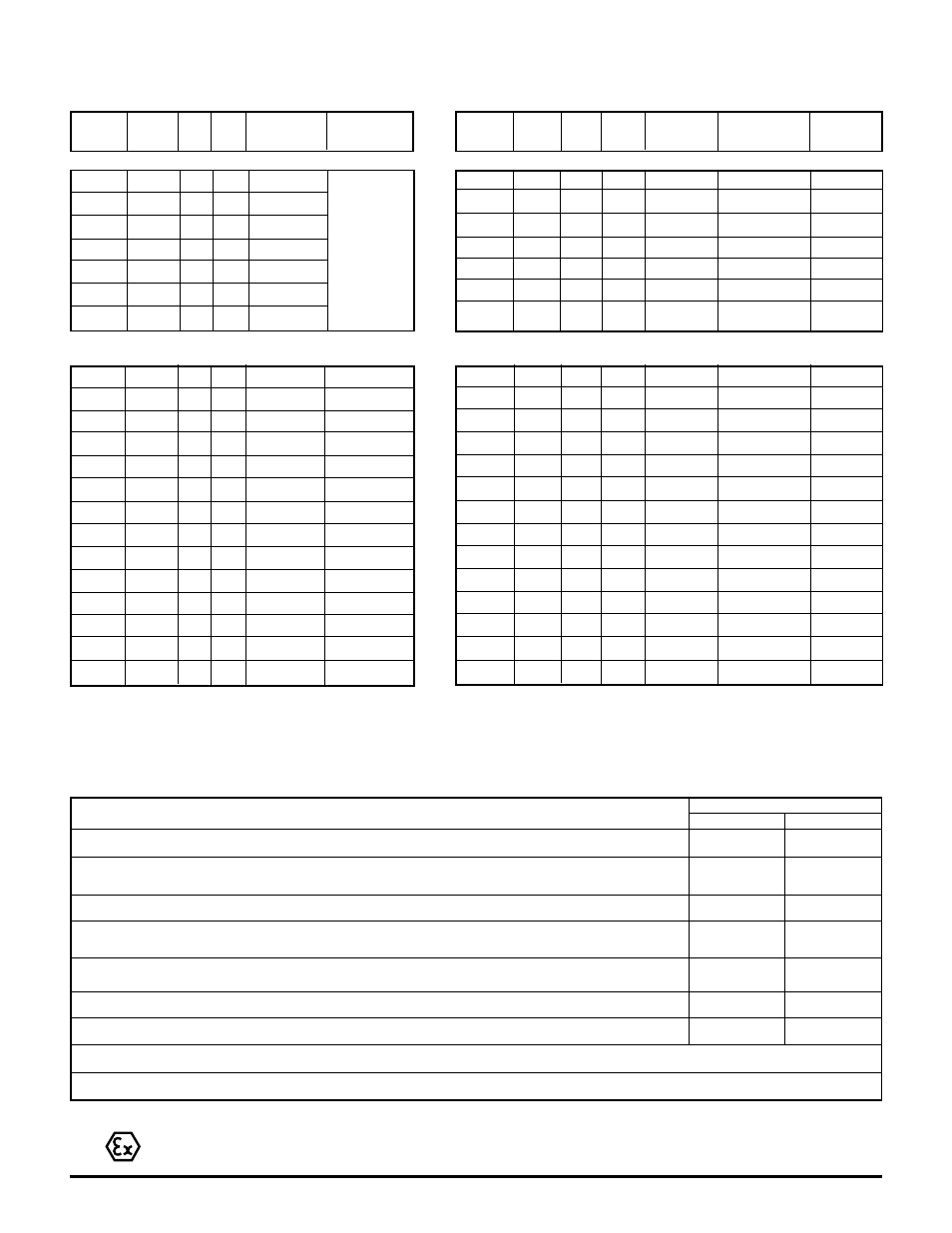

Models VTA1, VTA25, VTA1½, VTA40, VTA2, VTA50, VTA3 & VTA80

versassmsm-rev0510

Page 3

H =

Hytrel®

I

=

EPDM

N =

Neoprene

NG =

Neoprene Backup/PTFE Overlay

A

=

Aluminum

B =

Nitrile

CI =

Cast Iron

F

=

FDA White Nitrile

Surge Suppressor Model VTA3 Design level 2

Meaning of

Abbreviations:

Kit available to convert

to top porting

* Most other types available in dual ported design. See price book or consult factory for details.

Hytrel® are registered tradenames of E.I. du Pont. Santoprene® is a registered tradename of Exxon Mobil Corp. Versa-Matic is a registered tradename of Warren Rupp, Inc.

B-2-A

I-2-A

NG-2-A

N-2-A

V-2-A

B-2-CI

I-2-CI

NG-2-CI

N-2-CI

V-2-CI

B-2-SS

NG-2-SS

N-2-SS

V-2-SS

MATERIALS

Operating Temperatures

Maximum

Minimum

NITRILE: General purpose, oil-resistant. Shows good solvent, oil, water and hydraulic fluid resistance. Should not be used

with highly polar solvents like acetone and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons.

NEOPRENE: All purpose. Resistant to vegetable oils. Generally not affected by moderate chemicals, fats, greases and

many oils and solvents. Generally attacked by strong oxidizing acids, ketones, esters, nitro hydrocarbons and chlorinated

aromatic hydrocarbons.

HYTREL®: Good on acids, bases, amines, and glycols at room temperature.

VIRGIN PTFE: Chemically inert, virtually impervious. Very few chemicals are know to chemically react with Teflon®,

molten alkali metals, turbulent liquid or gases, fluorine and a few fluoro-chemicals such as chlorine trifluoride or oxygen

difluoride which readily liberate free fluorine at elevated temperatures.

FKM: Shows good resistance to a wide range of oils and solvents; especially all alipphatic, aromatic and halogenated

hydrocarbons, acids, animal and vegetables oils. Hot water or hot aqueous solutions (over 70

°

F) will attack FKM.

EPDM: Shows very good water and chemical resistance. Has poor resistance to oil and solvents, but is fair in ketones and

alcohols.

SANTOPRENE

®

: Injection molded thermoplastic elastomer with no fabric layer. Long mechanical flex life. Excellent abrasion

resistance.

STAINLESS STEEL: CF-8M equal to or exceeding ASTM specification A743 for corrosion resistant iron chromium, iron chromium nickel, and nickel

based alloy castings for general applications. Commonly referred to as 316 Stainless Steel in the pump industry.

ALLOY C: CW-12MW equal to or exceeding ASTM A494 specification for nickel and nickel alloy castings.

For specific applications, always consult the Versa-Matic

®

"Chemical Resistance Chart".

190°F

88°C

- 10°F

- 23°C

200°F

93°C

-10°F

-23°C

-20°F

-29°C

-35°F

-37°C

-40°F

-40°C

-40°F

-40°C

-40°F

-40°C

220°F

104°C

220°F

104°C

350°F

177°C

280°F

138°C

275°F

135°C

Surge Suppressor Model VTA80 Design level 2

2

SS

2

SS

2

SS

2

HC

2

HC

2

HC

2

HC

35 / 15.9

35 / 15.9

35 / 15.9

35 / 15.9

35 / 15.9

35 / 15.9

35 / 15.9

Surge Suppressor Model VTA2 Design level 2, continued

Surge Suppressor Model VTA50 Design level 2, continued

SS

SS

SS

HC

SS

HC

HC

2" BSPT

2" BSPT

2" BSPT

2" BSPT

1½" BSPT

1½" BSPT

1½" BSPT

2

2

2

2

2

2

2

NG-2-SS

N-2-SS

V-2-SS

I-2-HC

NG-2-HC

N-2-HC

V-2-HC

B

I

NG

N

V

B

I

NG

N

V

B

NG

N

V

A

A

A

A

A

CI

CI

CI

CI

CI

SS

SS

SS

SS

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3" BSPT

3" BSPT

3" BSPT

3" BSPT

3" BSPT

3" BSPT

3" BSPT

3" BSPT

3" BSPT

3" BSPT

3" BSPT

3" BSPT

3" BSPT

3" BSPT

PN10 80 mm DIN

PN10 80mm DIN

PN10 80mm DIN

PN10 80mm DIN

PN10 80mm DIN

PN10 80mm DIN

PN10 80mm DIN

PN10 80mm DIN

PN10 80mm DIN

PN10 80mm DIN

PN10 80mm DIN

PN10 80mm DIN

PN10 80mm DIN

PN10 80mm DIN

109 / 49.4

109 / 49.4

109 / 49.4

105 / 47.6

105 / 47.6

105 / 47.6

105 / 47.6

89 / 40.4

89 / 40.4

89 / 40.4

89 / 40.4

109 / 49.4

109 / 49.4

89 / 40.4

NG

N

V

I

NG

N

V

3" ANSI Style

3" ANSI Style

3" ANSI Style

3" ANSI Style

3" ANSI Style

3" ANSI Style

3" ANSI Style

3" ANSI Style

3" ANSI Style

3" ANSI Style

3" ANSI Style

3" ANSI Style

3" ANSI Style

3" ANSI Style

3" NPT

3" NPT

3" NPT

3" NPT

3" NPT

3" NPT

3" NPT

3" NPT

3" NPT

3" NPT

3" NPT

3" NPT

3" NPT

3" NPT

2" NPT

2" NPT

2" NPT

2" NPT

2" NPT

2" NPT

2" NPT

NG

N

V

I

NG

N

V

NG-2-SS

N-2-SS

V-2-SS

I-2-HC

NG-2-HC

N-2-HC

V-2-HC

B-2-A

I-2-A

NG-2-A

N-2-A

V-2-A

B-2-CI

I-2-CI

NG-2-CI

N-2-CI

V-2-CI

B-2-SS

NG-2-SS

N-2-SS

V-2-SS

B

I

NG

N

V

B

I

NG

N

V

B

NG

N

V

2

2

2

2

2

2

2

2

2

2

2

2

2

2

A

A

A

A

CI

CI

CI

CI

CI

SS

SS

SS

A

SS

S =

Santoprene®

V =

FKM (Fluorocarbon)

SS =

Stainless Steel

HC =

Alloy C

Materials of Construction continued:

Type Diaphragm Design Wetted

Porting

Porting

Code

Level Parts (Internal Tapered

Flange Style

Threads)

Shipping

Weight

lbs./kg

T

ype

Diaphragm Design Wetted

Porting

Porting

Code

Level

Parts (Internal Tapered

Flange Style

Threads)

II 2G Ex ia c IIC T5

II 2D c iaD 20 IP67 T100˚C

II 2 G c T5

II 3/2 G c T5

II 2 D c T100

o

C See page 15 for ATEX Explanation of Type Examination Certificate.