Surge suppressor, Model vta1 metallic construction, Service and operating instructions – Versa-Matic Versa-Surge Surge Suppressors for Air-Driven Diaphragm Pumps Metallic User Manual

Page 12: Caution important, Warning, Hazard warning

Model VTA1 Page 10

vta1mdl1sm-rev0510

®Versa-Matic is a registered tradename of Warren Rupp, Inc.

©2010 Warren Rupp, Inc.

Surge Suppressor

Model VTA1

Metallic Construction

SERVICE AND OPERATING INSTRUCTIONS

This Versa-Matic

®

Surge Suppressor is a completely automatic diaphragm fitted

surge suppressor to reduce the flow and pressure pulsations in a pumping system

characteristic of reciprocating type pumps.

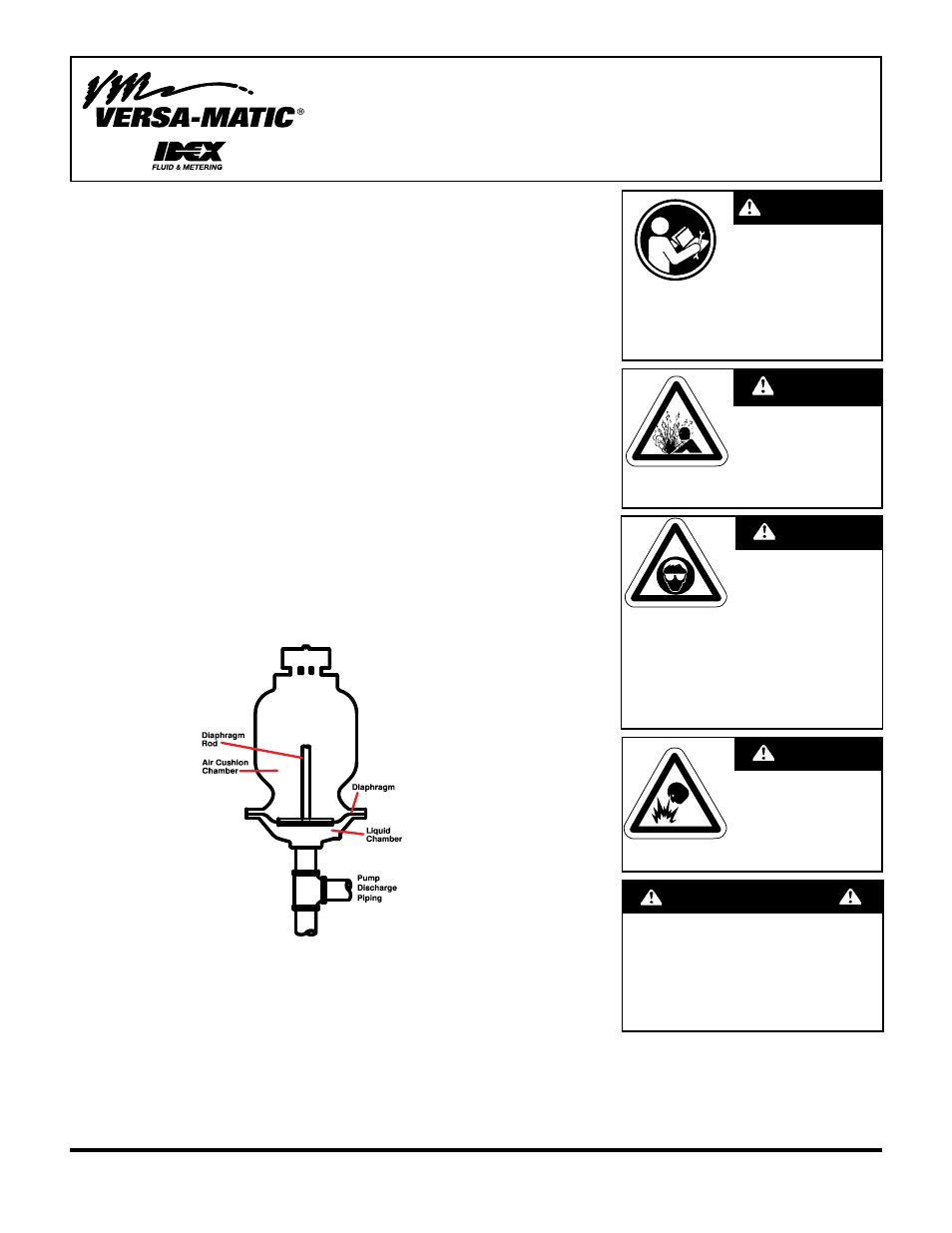

Principle of Operation: The Surge Suppressor uses a flexible diaphragm to separate a

liquid chamber from compressed air chambers. A rod connected to the center of

one diaphragm activates the air inlet and exhaust valves, which automatically admit

or exhaust air in the air chambers. This maintains the diaphragms in mid-range of

stroke for maximum surge suppression.

Installation: Locate the Surge Suppressor in discharge piping as close as possible

to the pump. The unit will operate in any position. Connect air inlet connection to

full plant air supply line before the air regulator to pump. Not to exceed 125PSI.

Service Instructions: When service is required, it is important to MAKE CERTAIN

THAT INLET AIR PRESSURE IS DISCONNECTED. The diaphragms are serviced

by simply removing the hex nuts or v-band, and removing the center spool casting.

When Virgin PTFE diaphragms are used in conjunction with the elastomeric

diaphragms they are placed over the “wetted” sides of each elastomeric diaphragm.

Inlet and exhaust air valves are located externally for easy access and service.

Warranty: This unit is guaranteed for a period of five years against defective

material and workmanship.

Before surge suppressor

operation, inspect all

gasketed fasteners for

looseness caused by

gasket creep. Re-torque

loose fasteners to prevent leakage. Follow

recommended torques stated in this manual.

CAUTION

IMPORTANT

Read these safety warnings

and instructions in this

manual completely, before

installation and start-up

of the pulsation dampener.

It is the responsibility of the purchaser to retain

this manual for reference. Failure to comply with

the recommendations stated in this manual

will damage the pulsation dampener, and void

factory warranty.

Before doing any maintenance

on the pulsation dampener,

be certain all pressure is

completely vented from the

pump, suction, discharge,

piping, and all other openings and connections.

Be certain the air supply is locked out or made

non-operational, so that it cannot be started

while work is being done on the pump. Be certain

that approved eye protection and protective

clothing are worn all times in the vicinity of the

pump. Failure to follow these recommendations

may result in serious injury or death.

WARNING

Take action to prevent static

sparking. Fire or explosion

can result, especially

when handling flammable

liquids. The pump, piping,

valves, containers or other

miscellaneous equipment

must be grounded. See page 8.

WARNING

POSSIBLE EXPLOSION HAZARD can result if

1, 1, 1, -Trichloroethance, Methylene Chloride

or other Halogenated Hydrocarbon solvents

are used in pressurized fluid systems having

Aluminum or Galvanized wetted parts. Death,

serious bodily injury and/or property damage

could result. Consult with the factory if you

have questions concerning Halogenated

Hydrocarbon solvents.

HAZARD WARNING