Val-Matic 3 Way Plug Valve User Manual

Page 6

M

P

(

t

li

t

a

h

R

s

li

k

v

h

s

b

fo

a

r

P

T

w

a

p

p

v

CAUTION:

actuator. T

to toxic or

MAINTENA

PACKING RE

7), it is recom

he actuator r

ine. To repla

he blind por

actuators, tu

hydraulic supp

Remove sma

shaft and key

ift actuator fro

key. Remove

valve shaft.

hook. Lubrica

set in place o

bend over the

follower with

actuator over

reinstall cover

PACKING R

The above pr

will result in t

actuator cann

procedure ca

possibility of

valve and dra

Drain Lin

Take precaut

hazardous fl

ANCE (Con

EPLACEMENT

mmended tha

removed. Th

ace the packi

rt position (p

rn off and

plies before p

all round cove

. Remove ac

om valve taki

e nuts (12) a

Remove old

ate new pack

one ring at a

e lips of the

2 shims (

r valve and r

r on actuator.

REPLACEME

rocedure with

the most relia

not be remove

an be follo

leakage dur

in the line.

ne before

tions agains

luids in the l

nt'd)

T: To replace

at the line be

e valve can

ng, first plac

port No. 2).

lock out e

proceeding.

er on actuato

ctuator mount

ng care not to

and lift follow

packing (7)

king with FDA

a time taking

packing ring

29) per bolt

reinsert key (

NT WITH

h removal of

able shaft sea

ed, the follow

wed. To

ring this proc

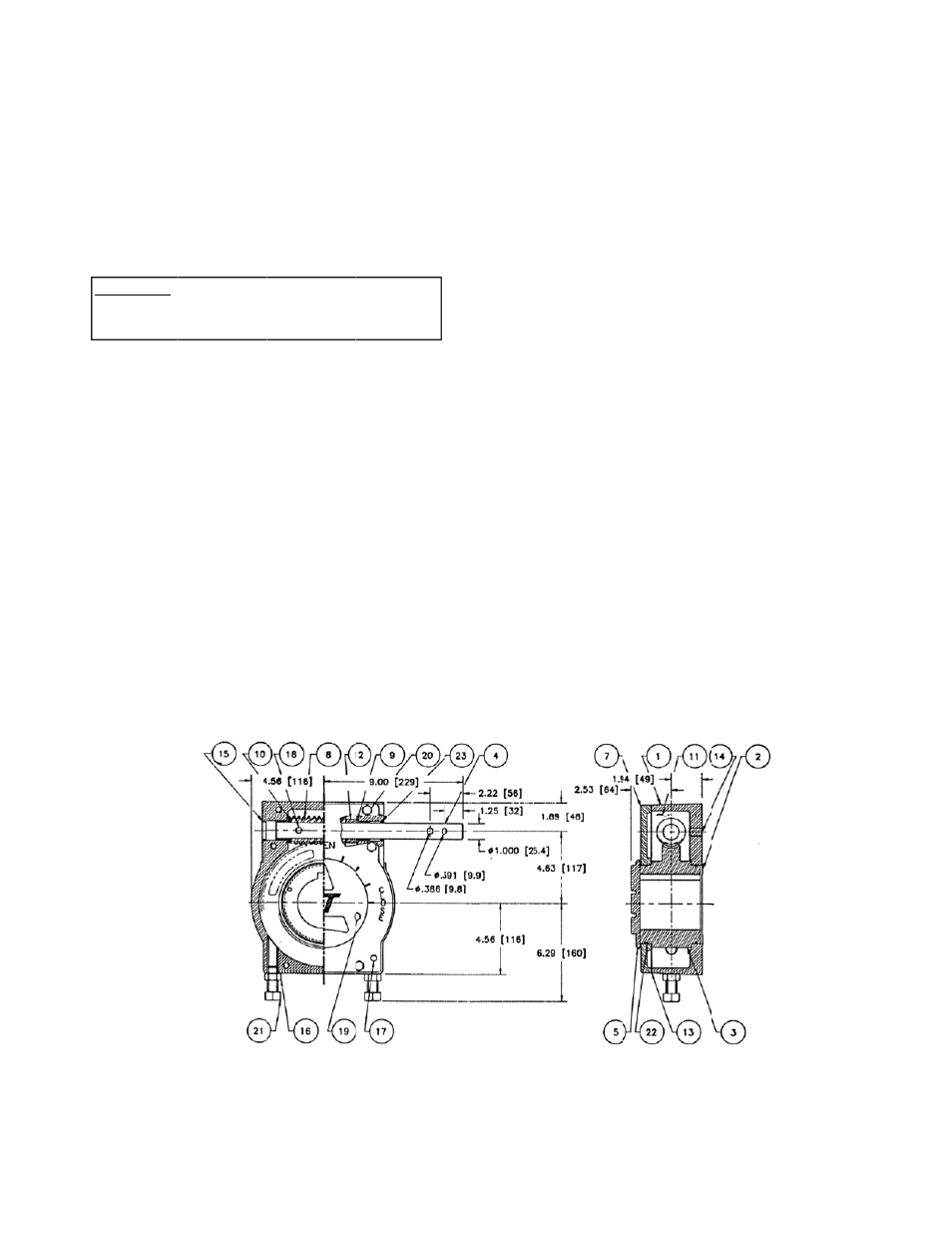

FIGURE

removing

st exposure

ine.

e the packing

e drained and

remain in the

e the plug in

For power

lectrical and

or to expose

ting bolts and

o lose square

wer (18) from

with packing

A grease and

g care not to

gs. Reinstal

t. Place the

(24). Finally,

ACTUATOR

f the actuator

al. But if the

wing alternate

prevent the

cedure, open

E 5. GEAR A

g

d

e

n

r

d

e

d

e

m

g

d

o

l

e

,

:

r

e

e

e

n

Rem

actu

with

New

allow

over

down

arou

reins

(18).

requ

GEA

actu

(8)

enga

turne

The

indic

grea

The

regu

is ob

inspe

coat

even

mov

Mob

with

ACTUATOR C

move nuts (1

ator. Remov

packing hoo

w packing ring

w insertion a

rlap. Install

n towards th

und the shaf

sert nuts (12

. V-packing

uires light com

AR ACTUATO

ator is shown

mounted on

ages a worm

ed, it drives t

rotation of th

cator (5). T

ase in a cast i

gear box is

ular maintenan

bserved, the c

ected for we

ed with grea

n and smooth

ing parts wit

bilux EP2. Bu

grease.

CONSTRUCT

12) and slide

ve packing a

ok. Cut rings

gs should be

round the sh

rings one at

he valve. S

ft. Pull dow

) with 2 shim

g is pressur

mpression.

OR MAINTEN

n in Figure 5 a

an input s

m wheel (3).

the wheel thr

he valve plug

he gears are

ron housing (

factory lubric

nce is require

cover can be

ear. All mo

ase. The gr

h consistency

th an EP-2 g

uried units sh

TION

e follower (1

adapters and

s with knife to

e cut at a 45

o

haft and prov

t a time with

Stagger all jo

wn follower

ms (29) unde

re assisted

NANCE: A ty

and consists

shaft (4). T

When the

rough 360

o

is displayed b

e lubricated

(1).

cated and se

ed. If difficult

e removed an

oving parts s

rease should

y. If needed

grease such

hould be pack

18) up to

rings (7)

o remove.

o

slope to

vide some

h the lips

oints 180

(18) and

er follower

and only

pical gear

of a worm

The worm

e worm is

of rotation.

by the top

with EP2

ealed. No

operation

nd the unit

should be

have an

d, coat all

as Mobil

ked 100%