Val-Matic 3 Way Plug Valve User Manual

Page 5

M

T

lu

e

T

3

T

m

O

r

P

f

in

r

c

a

A

p

If

d

t

b

a

V

m

w

P

e

f

p

a

w

d

fo

s

s

T

o

r

h

1

in

s

r

t

CAUTION:

should be

hammer.

MAINTENA

The Cam Cen

ubrication o

exercising an

The exercising

360 degrees t

The recomme

months or ann

Over the life

regular adjust

POSITION AD

factory-set to

nto the seat

require adjust

consult the fa

arrow should

Adjustable ind

precise positio

f the valve is

due to wear,

he left or rig

bolt on the ac

and moved di

Valves that h

may require

wear. See the

PACKING A

equipped with

factory-set fo

pressure ass

adjustment. H

wear, a smal

develops, mo

follower (18)

stop the leak

shim or replac

THRUST BEA

of the plug a

raising and lo

has a 5 degre

1/16 in. will p

nterference.

should first b

right to see if

hen a thrust b

Opening an

e done slow

ANCE

ntric

®

Plug Va

or maintenan

nd occasiona

g is achieved

to verify smoo

ended interval

nually if the v

e of the valv

tments may b

DJUSTMENT

seal with p

t. Reverse p

tment of the

actory. The

d point to th

dicator screws

oning of the p

s found to le

the plug pos

ht until a sea

ctuator cover

rectly under t

have been in

inspection of

e Disassembl

ADJUSTMENT

h a set of V-

or drop-tight

isted and do

However, dep

l adjustment

ve shims (29

and tighten

. If the leak

ce the packing

ARING ADJU

against the s

wering the pl

ee taper, so e

provide an ad

If leakage in

e rotated 1-2

the leak stop

bearing adjus

nd Closing o

wly to prev

alve requires

nce other t

al inspection

d by fully rotat

oth operation.

l for exercisin

valve is regula

ve, inspectio

e needed as

T: The stand

ressure push

ressure appl

thrust bearin

closed posi

he port to

s in slotted h

plug.

eak in the clo

sition should

al is made.

r should then

the target arro

service for s

f the plug fo

ly Instructions

T: The to

-shaped pack

service. Th

oes not norm

pending on lin

can be mad

9) from under

the follower

persists, rem

g.

USTMENT: T

seat can be

lug in the valv

very vertical a

dditional .005

the valve occ

2 degrees to

ps. If the lea

stment is nece

of the valve

vent water

no scheduled

than regular

of the plug

ting the valve

.

ng is every six

arly operated

n and some

given below.

dard valve is

hing the plug

ications may

ng assembly

tion indicator

be shut off

oles allow for

osed position

be moved to

The indicator

be loosened

ow.

several years

or damage or

s on page 8.

op shaft is

king which is

e packing is

mally require

ne media and

de. If a leak

to above the

bolts (19) to

move another

The tightness

adjusted by

ve. The seat

adjustment of

in. of rubber

curs, the plug

o the left and

ak still occurs

essary.

d

r

.

e

x

.

e

s

g

y

;

r

.

r

n

o

r

d

s

r

s

s

s

e

d

k

e

o

r

s

y

t

f

r

g

d

,

The

posit

seat

1. Ro

su

2. L

n

3. C

r

To d

1. Ro

su

2. Ti

th

3. C

ro

If lea

has

drain

dam

F

thrust bearin

tioned with

ing interferen

otate the low

upport plate.

Lock the supp

uts (12) again

Check for lea

rotate through

decrease the s

otate the upp

upport plate.

ighten the low

he support pla

Check for lea

otate through

akage continu

been adjus

ned, and the

age or debris

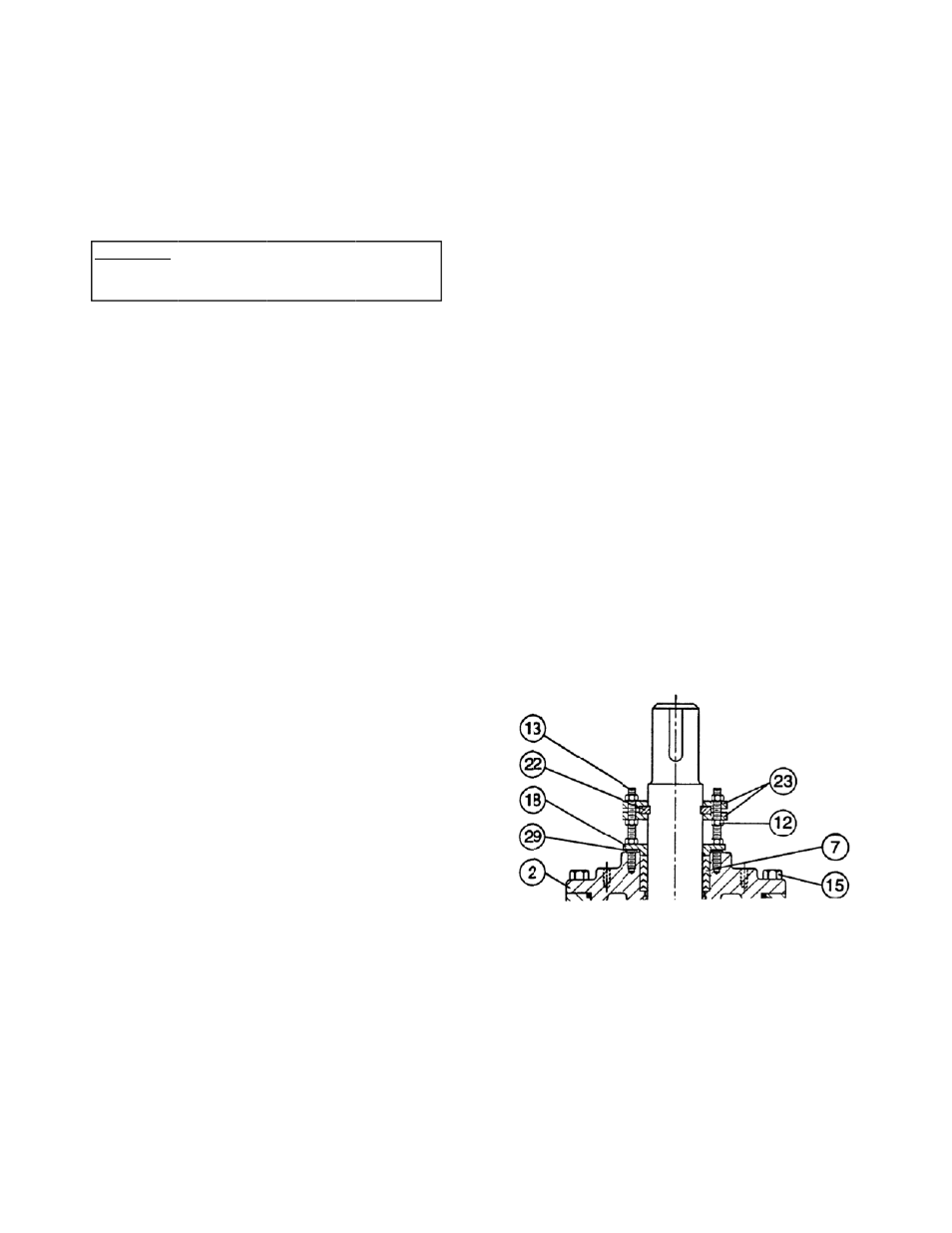

FIGURE 4. T

ng support pla

hex nuts (1

nce, lower the

wer nuts (12)

port plate dow

nst the top su

kage and ve

h the seat sm

seating interfe

per nuts (12)

wer nuts unti

ates touch the

kage and ve

the seat smo

ues to occur a

sted, then t

cover remov

s in the valve.

THRUST BEA

ates (23) are

2). To incr

e plug:

1/2 turn away

wn by tightenin

upport plate (2

erify that the

moothly.

erence, raise

1/2 turn away

il the plug is

e upper nuts.

erify that the

oothly.

after the thrus

the valve s

ved to inspec

.

ARING ASSE

e vertically

rease the

y from the

ng the top

23).

valve will

the plug.

y from the

lifted and

valve will

st bearing

hould be

ct for plug

MBLY