Val-Matic Swing-Flex Check Valve User Manual

Page 5

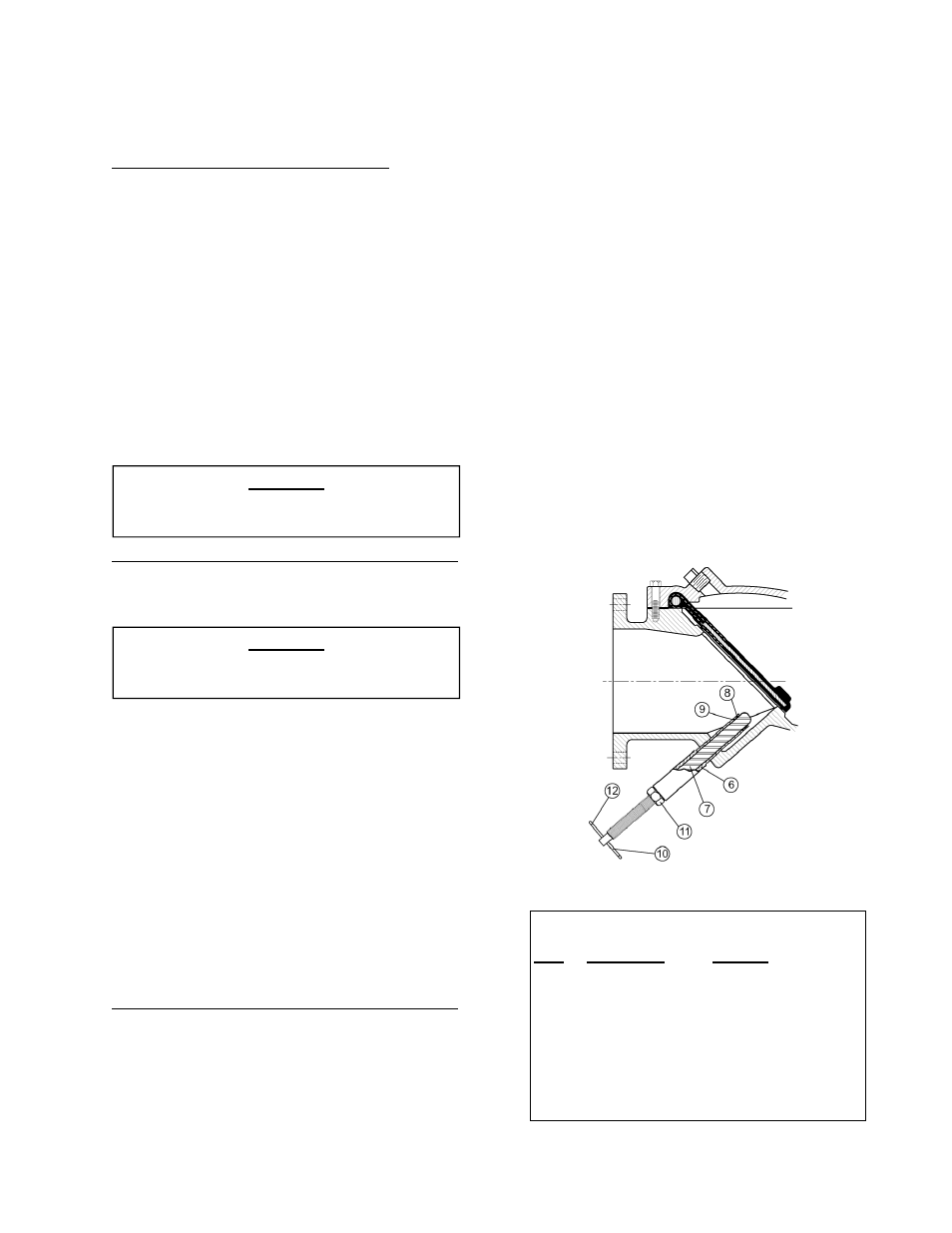

Backflow Actuator Parts List

Item Description Material

6

Bushing

Lead-Free Brass

7

Rod

Stainless Steel

8

Rod Wiper*

Molythane

9

O-Ring*

Buna-N

10

Handle

Stainless Steel

11

Jam nut

Brass

12

Cap*

Vinyl

*Recommended Spare Part

BACKFLOW ACTUATOR FIELD INSTALLATION AND MAINTENANCE (OPTIONAL)

BACKFLOW ACTUATOR OPERATION:

An optional backflow actuator assembly is

available which can be easily installed in the field.

The actuator is not designed to operate at the

valve’s Maximum Working Pressure rating.

Therefore, prior to using the actuator, close the

pump isolation valve and bleed off line pressure.

To operate, turn the handle clockwise. This will

open the valve disc allowing backflow through the

valve. The handle should turn easily. When the

actuator is fully extended into the valve, the disc

will be partially open. Upon completion of the back

flushing operation, turn the handle counter-

clockwise and the valve will automatically return to

the closed position. Lock the actuator in the

closed position with the jam nut provided. The

system is again ready for normal operation.

BACKFLOW ACTUATOR FIELD INSTALLATION:

The backflow actuator is supplied as an optional

assembly from the factory, which is shipped loose

with the valve.

1. Depressurize and drain the pipeline.

2. Score the coating around and remove the pipe

plug in the bottom boss of the valve.

3. Inspect the backflow rod and place in the non-

extended position. (The rod should extend

about 1" past the end of the brass bushing.)

Apply Teflon thread sealant to brass threads.

4. Insert the threaded end of the assembly into

the valve boss. Slowly turn the assembly into

the boss taking care not to cross-thread the

bushing. Continue turning the assembly into

the valve for a tight fit.

BACKFLOW ACTUATOR SEAL REPLACEMENT:

There are two parts (8 & 9) on the backflow

actuator that are subject to wear. To replace the

seals, the pipeline must first be depressurized and

drained. Next, remove the backflow assembly

from the valve by turning the brass bushing (6)

counter-clockwise. Disassemble the actuator as

follows:

1. Remove one of the vinyl caps (12).

2. Remove the T-Handle (10) and jam nut (11)

from the rod (7).

3. Remove the rod (7) from the bushing (6) by

screwing in the rod fully clockwise and pull the

rod through the valve end of the bushing (6).

4. Lubricate new seals with FDA approved grease

such as Lubriko #CW-606 and install in the

bushing end grooves.

5. Clean, lubricate, and reinstall rod in bushing.

6. Re-install jam nut (11) and T-Handle (10).

7. Place vinyl cap (12) on handle (10).

8. Apply Teflon thread sealant to bushing and

carefully thread into valve taking care not to

cross-thread the bushing.

FIGURE 3. BACKFLOW ACTUATOR ASSEMBLY

WARNING

Relive line pressure before using backflow

actuator or damage may occur.

WARNING

Remove of the bottom plug while under

pressure may cause bodily harm.