Val-Matic Swing-Flex Check Valve User Manual

Page 4

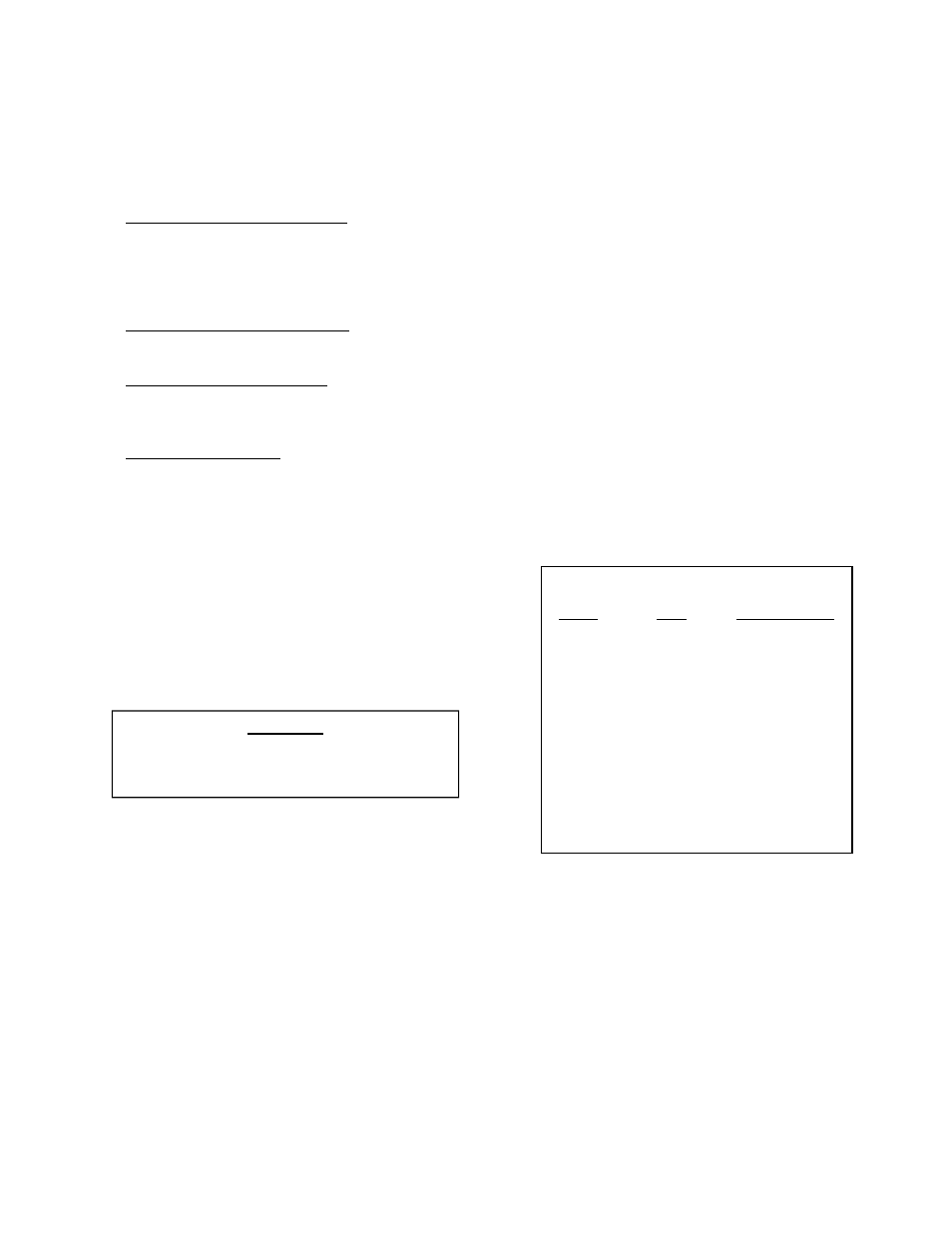

Table 2. Valve Cover Bolt Torques

Valve

Size

Torque (ft-lbs)

2”-2.5”

1/2"

75

3”

7/16"

50

4”

1/2"

75

6”

5/8"

150

8”

5/8"

150

10”

7/8"

400

12”-20”

7/8”

400

24”

1”

500

30”

1 1/8”

600

36”

1 1/4”

900

42”

1 1/2"

1,400

48”

1 1/2”

1,400

TROUBLESHOOTING

Several problems and solutions are presented

below to assist you in troubleshooting the valve

assembly in an efficient manner.

Leakage at Bottom Actuator: Remove line

pressure and exercise actuator. If leak persists,

replace seals in actuator; see the Backflow

Actuator Seal Replacement Procedure on page

4.

Leakage at Cover or Flanges: Tighten bolts,

replace cover seal.

Valve Leaks when Closed: Inspect disc for

damage and replace. Inspect metal seating

surface and clean if necessary.

Valve Does not Open: Check for obstruction in

valve or pipeline; see Disassembly procedure on

page 4. Operating pressure may be less than

cracking pressure. If less than 0.5 psig, review

application with factory.

DISASSEMBLY

The valve can be disassembled without removing

it from the pipeline. Or for convenience, the valve

can be removed from the line. All work on the

valve should be performed by a skilled mechanic

with proper tools and a power hoist for larger

valves. Disassembly may be required to inspect

the disc for wear or the valve for deposits.

1. Relieve pressure and drain the pipeline. Refer

to Figure 2 on page 2. Remove the cover bolts

(5) on the top cover.

2. Pry cover (2) loose and lift off valve body. 12”

and larger valves have tapped holes in cover

for lifting eyes.

3. Remove disc (3) and inspect for cracks, tears

or damage in rubber sealing surface.

4. Clean and inspect parts. Replace worn parts

as necessary and lubricate parts with FDA

grease such as Lubriko #CW-606.

RE-ASSEMBLY

All parts must be cleaned. Gasket surfaces should

be cleaned with a stiff wire brush in the direction of

the serrations or machine marks. Worn parts,

gaskets and seals should be replaced during

reassembly.

1. Lay disc (3) over seat with beaded seating

surface directed down.

2. Lay cover gasket (4) and cover (2) over bolt

holes and disc hinge. Where o-ring seal is

provided, place o-ring into body groove. O-ring

may be held in place with compatible grease

for re-assembly. Food grade grease should be

used for standard Buna-N o-rings. For EPDM

o-rings, silicone grease should be used.

3. Insert lubricated bolts (5) noting that the bolts in

the hinge area are longer than the other cover

bolts.

4. Cover bolts should be tightened to the following

specifications during assembly.

WARNING

The line must be drained before removing

the cover or pressure may be released

causing bodily harm.