Val-Matic Swing-Flex Check Valve User Manual

Page 3

Table 1. Flange Bolt Torques

Valve Bolt Recom. Max.

Size Dia Torque Torque

(in) (in) (ft-lbs) (ft-lbs)

3

5/8

25

90

4

5/8

25

90

6

3/4

30

150

8

3/4

40

150

10

7/8

45

205

12

7/8

65

205

14

1

80

300

16

1

80

300

18

1 1/8

100

425

20

1 1/8

100

425

24

1 1/4

150

600

30

1 1/4

160

600

36

1 1/2

300

900

42

1 1/2

300

900

48

1 1/2

300

1,000

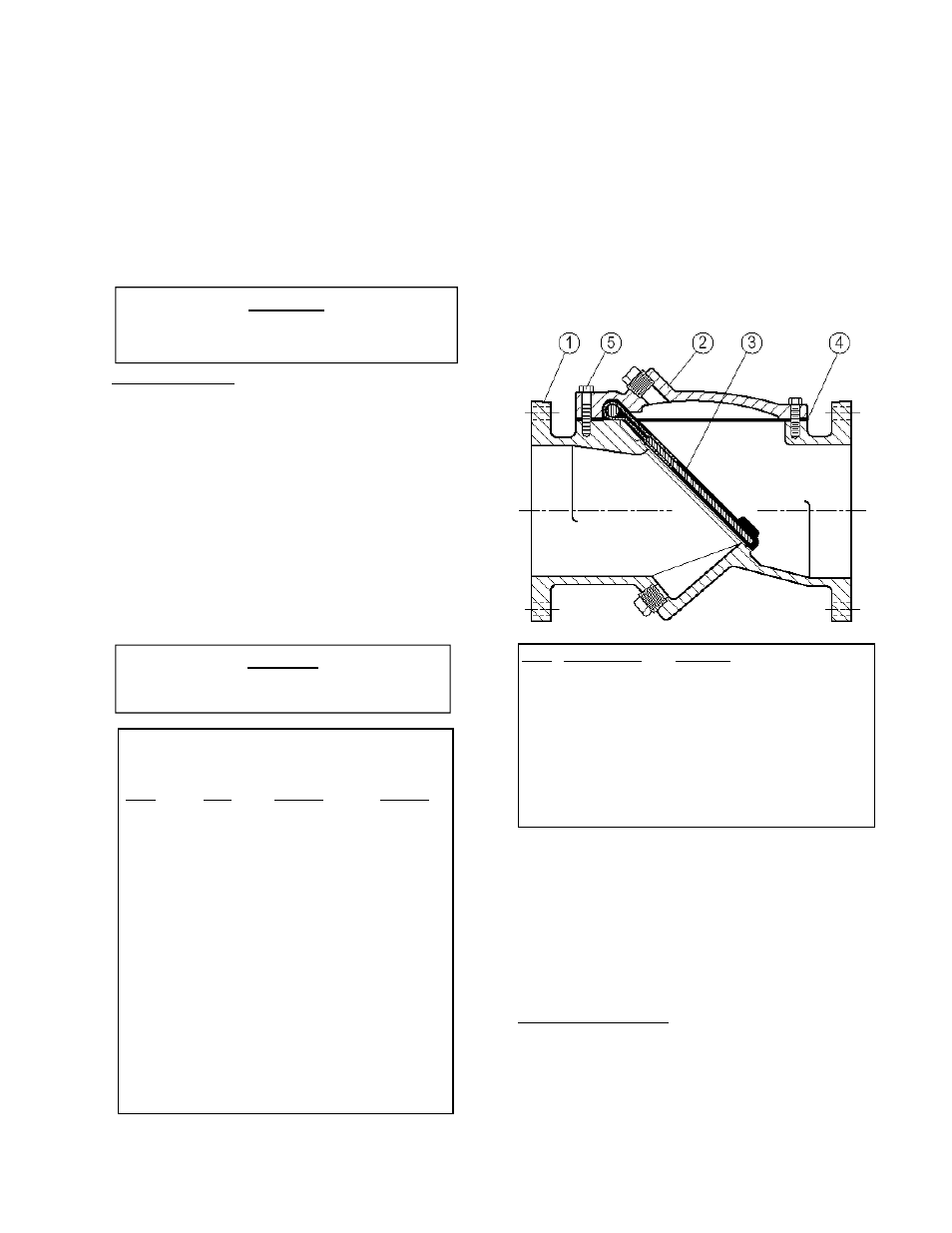

Item Description

Material

1

Body

Ductile Iron – 250 psi

Cast Iron – 150 psi

2

Cover

Ductile Iron – 250 psi

Cast Iron – 150 psi

3

Disc*

Steel With Buna-N Facing

4

Cover Seal*

Buna-N or Non-Asbestos

5

Cover Bolt

Alloy Steel

*Recommended Spare Part

INSTALLATION

Correct installation of the Swing-Flex

is important

for proper operation. It may be installed in either

horizontal or vertical flow-up applications.

However, when horizontal, the valve must be

installed with the nameplate facing up and the

cover level. In all installations, the flow arrow cast

in the valve cover must be pointed in the direction

of flow during normal system operation.

FLANGED ENDS: Flanged valves should only be

mated with flat-faced pipe flanges equipped with

full-face resilient gaskets. The valve and adjacent

piping must be supported and aligned to prevent

cantilevered stress on the valve. Once the flange

bolts or studs are lubricated and inserted around

the flange, tighten them uniformly hand tight. The

tightening of the bolts should then be done in

graduated steps using the crossover tightening

method. Recommended lubricated torque values

for use with resilient gaskets (75 durometer) are

given in Table 1. If leakage occurs, allow gaskets

to absorb fluid and check torque and leakage after

24 hours. Do not exceed bolt rating or extrude

gasket.

VALVE CONSTRUCTION

The standard Swing-Flex

Check Valve is

constructed of rugged cast iron with a rubber

encapsulated disc. See the specific Materials List

submitted for the order if other than standard cast

iron construction. The disc is the only moving part

assuring long life with minimal maintenance. The

general details of construction are illustrated in

Figure 2. The body (1) is flanged for connection to

the pipeline with an open top sealed with a cast

cover (2). The disc (3) is retained by the cover.

FIGURE 2. CHECK VALVE CONSTRUCTION

MAINTENANCE

The Swing Flex

Check Valve requires no

scheduled lubrication or maintenance. For service

or inspection, the valve can be serviced without

removal from the line.

VALVE INSPECTION: If inspection of the valve is

required, follow the Disassembly Instructions given

on page 3.

WARNING

Do not use threaded holes in cover for

lifting the valve. Serious injury may result.

CAUTION

The use of ring gaskets or excessive bolt

torque may damage valve flanges.