Val-Matic Threaded Silent Check Valve User Manual

Page 4

3

DISASSEMBLY

The valve should be removed from the pipeline for

disassembly. A skilled mechanic with proper tools

should perform all work on the valve. Refer to

Figure 2.

1.

Clamp the downstream end of the valve body

(1) lightly in a vise using the hex connection

on the valve body. Do not over-clamp the

valve or permanent distortion and leakage

may occur. Remove the seat end of the valve

using a wrench on the hex ends and unthread

the body seat in a counterclockwise direction.

2.

Lift up the disc assembly (3) from the body.

3.

Examine the Teflon seat (2) and inspect the

mating body seating surface for damage.

Some minor dents and discoloration are

normal. Grooves or wear areas will cause

leakage and requires valve replacement.

4. Remove spring (4) and check for wear or

cracks.

REASSEMBLY

All parts must be clean and gasket surfaces should

be cleaned with a stiff wire brush in the direction of

the serrations or machine marks. Worn parts,

gaskets, and seals should be replaced during

reassembly.

1.

Insert spring (5) into body (1).

2.

Lay disc (3) over the spring.

3.

Install the seat half of the body making sure

that the body washer (5) is in place. Tighten

the body pieces as a minimum to the torques

shown in Table 2. If leakage is found during

operation, elevate the torques until leakage

stops.

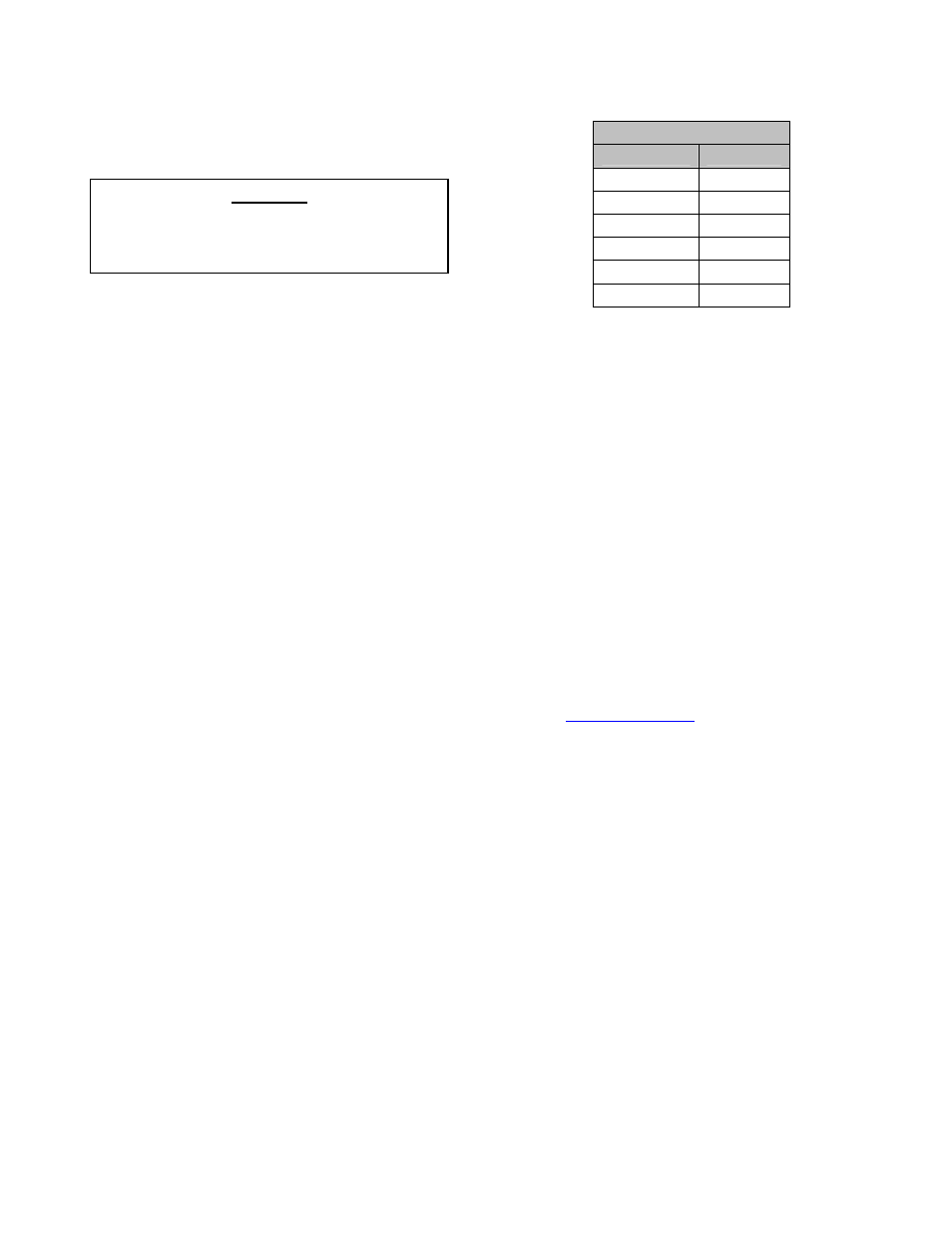

Body Assembly Torque

Valve Size

Torque

1/2” 50

ft-lbs

3/4” 75

ft-lbs

1” 100

ft-lbs

1-1/4” 125

ft-lbs

1-1/2” 150

ft-lbs

2” 200

ft-lbs

TABLE 2. ASSEMBLY TORQUES

PARTS AND SERVICE

Parts and service are available from your local

representative or the factory. Make note of the

Valve Size and Model Number located on the valve

nameplate and contact:

Val-Matic Valve and Manufacturing Corp.

905 Riverside Drive

Elmhurst, IL 60126

Phone:

(630)

941-7600

Fax: (630) 941-8042

www.valmatic.com

A sales representative will quote prices for parts or

arrange for service as needed.

WARNING

The line must be drained before removing

the valve or pressure may be released

causing injury.