Val-Matic Threaded Silent Check Valve User Manual

Page 2

1

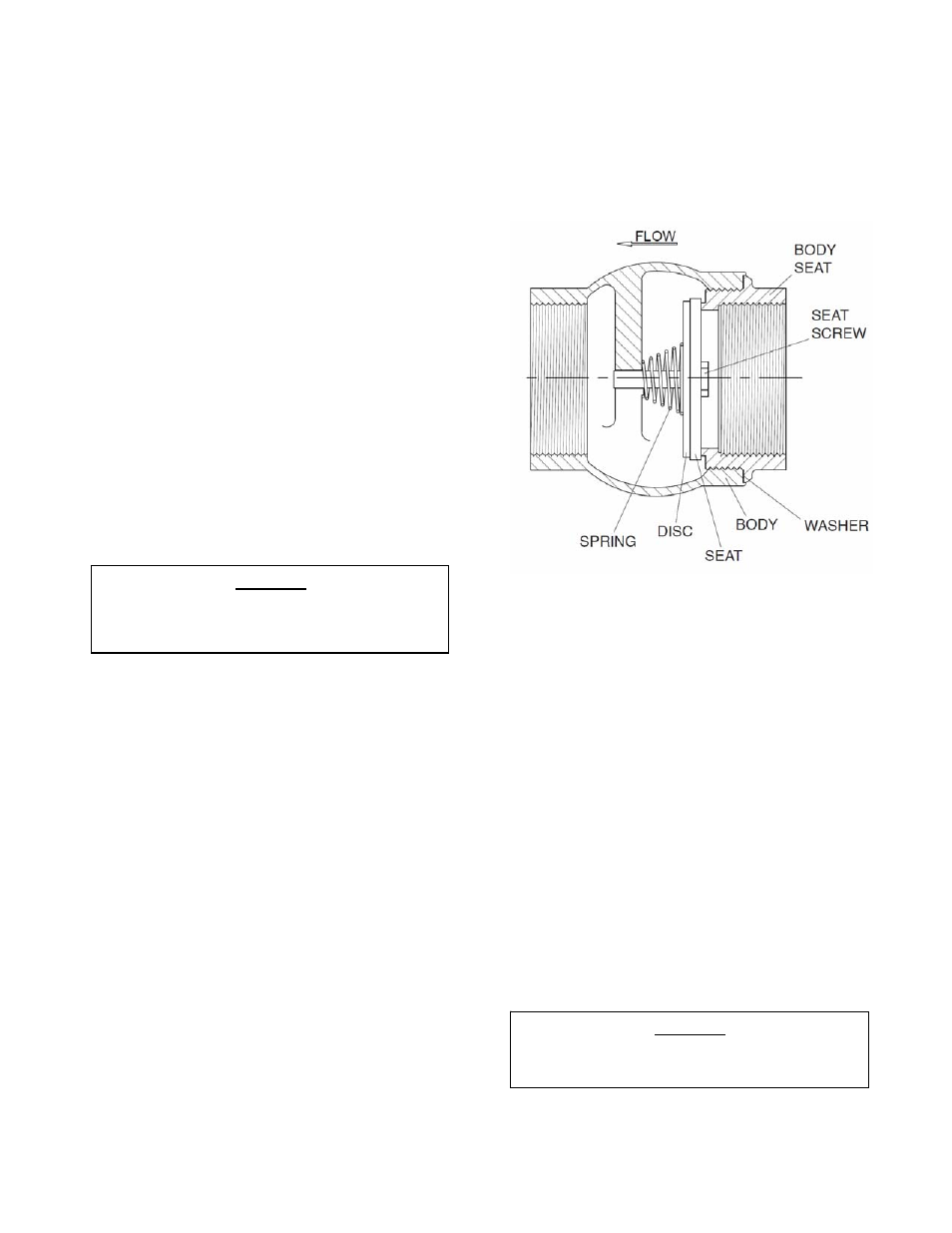

THREADED STYLE SILENT CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

This manual will provide you with the information to

properly install and maintain the valve to ensure a

long service life. The Threaded Silent Check Valve

is ruggedly constructed of lead-free bronze to give

years of trouble free operation. The valve should be

installed in horizontal or vertical pipes carrying clean

water.

The Threaded Silent Check Valve is designed to

open fully to provide flow in the forward direction and

close rapidly upon flow reversal. The valves are

used to prevent reverse flow through pumps or in

piping systems. The size and cold working pressure

(250 CWP) are marked on the body for reference.

This valve is not intended for fluids containing

suspended solids such as wastewater.

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in shipment.

The valves should remain boxed, clean and dry until

installed to prevent weather related damage. For

long term storage, no special provisions are needed.

DESCRIPTION OF OPERATION

The Threaded Silent Check Valve is designed to

prevent reverse flow automatically. On pump start-

up, the flow of water enters the valve from the seat

end (right side in Figure 1) and forces the disc open,

allowing the passage of fluid through the valve.

On pump shut-down, the spring closes the disc

rapidly before a flow reversal takes place. This type

of closure, which prevents flow reversal, is the factor

which provides “silent” operation and reduces water

hammer associated with check valve slam.

The valve body is supplied with NPT tapered

threads on each end for installation in pipelines.

FIGURE 1. THREADED SILENT CHECK VALVE

INSTALLATION

The installation of the valve is important for its

proper operation. The flow arrow on the valve body

must point in the direction of flow when the system is

in operation. The valve can be installed in horizontal

or vertical lines with the flow up or down.

Three diameters of straight pipe upstream of the

valve are recommended to prevent turbulent flow

streams through the valve, which can cause

vibration and wear.

When installed in horizontal lines, the check valve

does not have a specific upward orientation. Insert

pipe nipples with thread sealant or thread tape and

tighten while securing valve with a wrench on the

body end nearest the pipe nipple.

CAUTION

The use of excessive torque can damage the

valve.

CAUTION

This valve is not intended for fluids

containing suspended solids or hazardous

fluids.