Val-Matic Threaded Silent Check Valve User Manual

Page 3

2

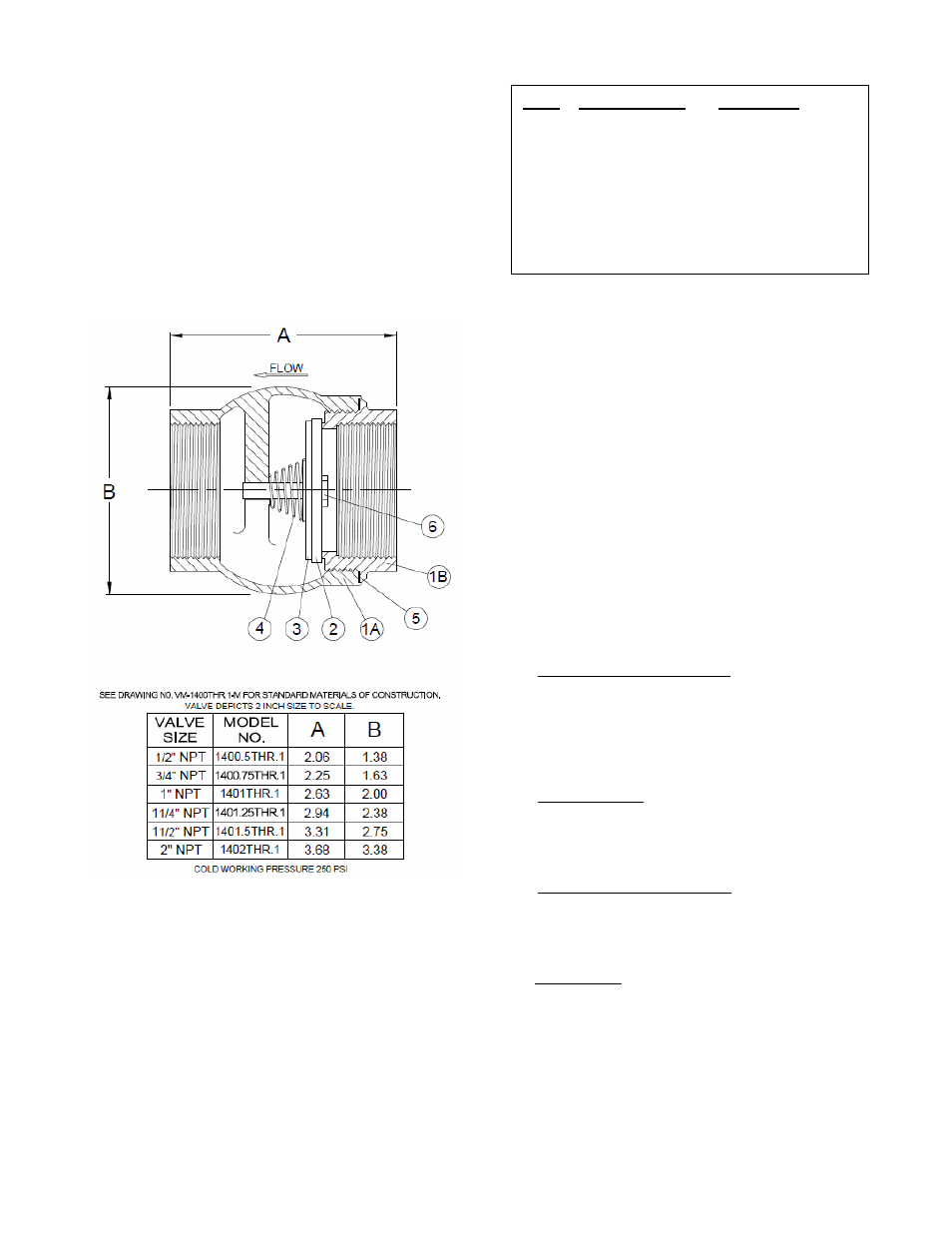

VALVE CONSTRUCTION

The standard threaded check valve body (1) is

constructed of lead-free bronze and is certified to

comply with NSF/ANSI 372, “Drinking Water System

Components – Lead Content.” The internal metal

components are bronze or stainless steel. The body

(1) is threaded and designed to accept pipe nipples

with NPT pipe threads. The disc (3) and spring (4)

are the only moving parts and require no

maintenance or lubrication. The general details of

construction are illustrated in Figure 2.

FIGURE 2. VALVE CONSTRUCTION

TABLE 1. CHECK VALVE PARTS LIST

MAINTENANCE

Threaded Silent Check Valves require no scheduled

lubrication or maintenance.

INSPECTION: Periodic inspection for leakage can

be performed by listening for leakage noise from the

valve while the pump is shut down. If leakage is

heard, drain the pipeline, remove the valve, and

inspect the seating surfaces for wear or mineral

deposits. Clean or replace the valve as needed.

TROUBLESHOOTING

Several problems and solutions are presented below

to assist you in troubleshooting the valve assembly

in an efficient manner.

Valve Chatters or Vibrates: Verify that velocity

is at least 4 feet per second. Noise sounding

like rocks in the line can be cavitation due to

high velocities, low downstream pressure, or an

upstream expanded. Verify that there are three

diameters of straight pipe upstream.

Valve Leakage: Drain line, remove valve, and

inspect seating surfaces for debris or damage. If

body washer is leaking, apply torque to the two

body pieces.

Valve Does Not Pass Flow: Check flow arrow

direction on valve body. Verify that downstream

isolation valve is open and there is no line

blockage downstream.

Valve Slams: Remove valve and inspect spring.

ITEM DESCRIPTION

MATERIAL

1

Body

Lead Free Bronze

2 Seat

Teflon

3

Disc

Lead Free Bronze

4 Spring

Stainless

Steel

6

Seat Screw

Lead Free Bronze

Spare Parts are not available for this valve.

A replacement valve is recommended.