Val-Matic 30 and Larger Butterfly Valve User Manual

Page 6

5

VALVE T-BOLT RECOM. MAX.

SIZE DIA TORQUE TORQUE

(in) (in) (ft-lbs) (ft-lbs)

30

1

75

120

36

1

75

120

42

1-1/4

75

150

48

1-1/4

75

150

TABLE 2. MECHANICAL JOINT NUT TORQUES

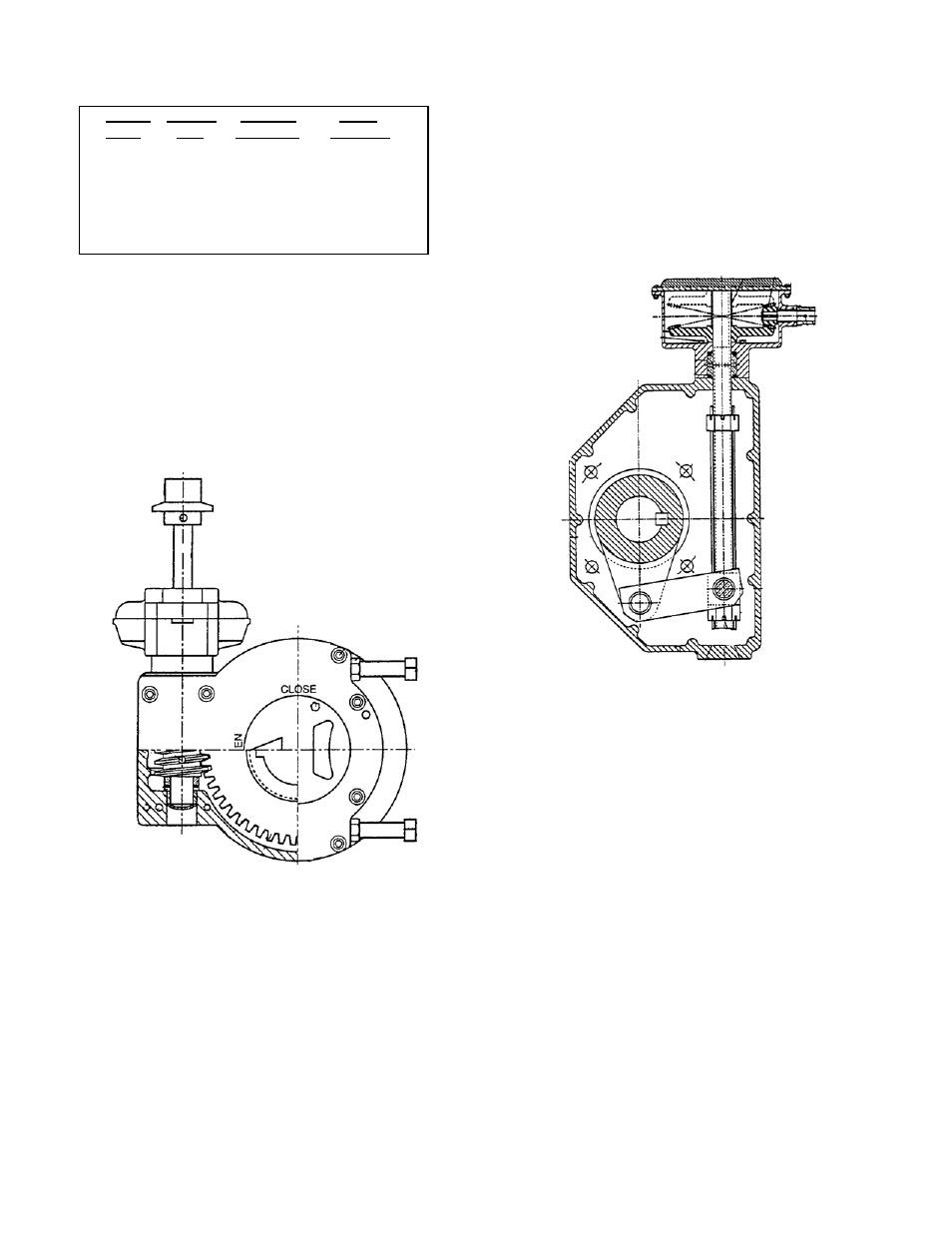

GEAR OPERATED VALVES: Butterfly Valves are

available with a two types of manual gear actuator.

A worm-gear actuator (Figure 6) has a multi-turn

worm that drives a large sector gear through 90

degrees of rotation. Worm gears provide uniform

motion and torque multiplication throughout the stroke.

A spur gear mounted on the input side provides

additional torque.

FIGURE 6. WORM GEAR ACTUATOR

A traveling nut actuator (Figure 7) has a threaded rod

that drives a nut from one end of the housing to

another. The traveling nut in turn drives a slotted lever

through 90 degrees of rotation. Traveling nut actuators

provide slower rotation and greater torque

multiplication at the ends of travel. A bevel gear

mounted on the input side of the actuator provides

additional torque.

FIGURE 7. TRAVELING NUT ACTUATOR

Both gear types are self-locking and multiply the

turning force on the handwheel or nut so that valves

can be operated with ease. A clamp-on chainwheel kit

can also be used for installations high above the floor.

An indicator on the top of the actuator housing

indicates the position of the valve plug. The

handwheel or nut must be rotated through 35-290 turns

(depending on model) to open or close the butterfly

valve. The direction of rotation to open the valve is

indicated on the 2" square actuator nut and handwheel.

The standard direction of rotation is open left or

counter-clockwise to open. Nuts with opposite rotation

(open right) will be painted red to indicate their special

rotation.

GEAR ACTUATOR ADJUSTMENT: The standard

gear actuator is provided with factory-set open and

closed position stops to properly center the closed disc

seal in the body seat. No field adjustment is

necessary.