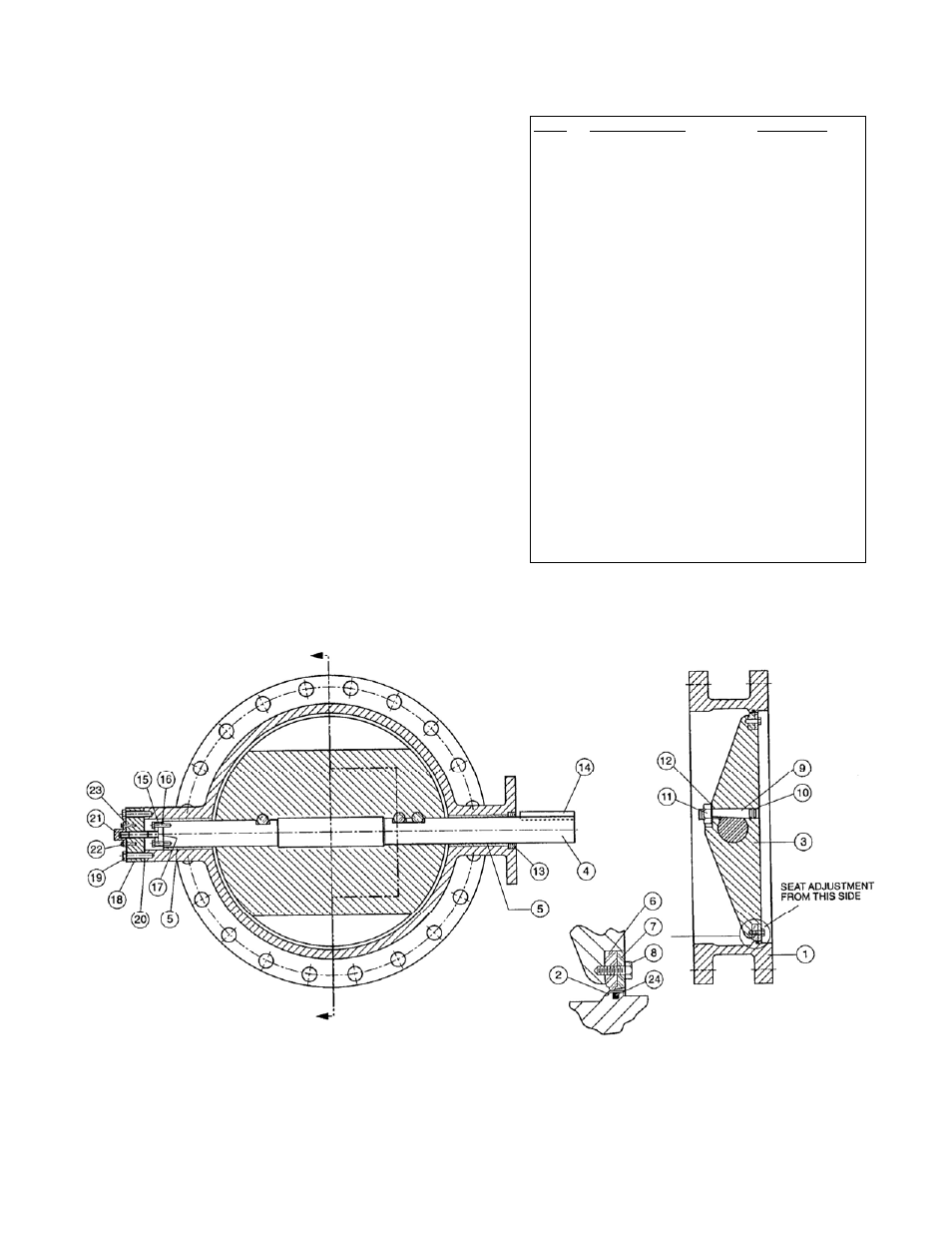

Valve construction – Val-Matic 30 and Larger Butterfly Valve User Manual

Page 3

2

ITEM DESCRIPTION

MATERIAL

1

Body

Gray or Ductile Iron

2

Body Seat

Stainless Steel

3

Disc

Ductile Iron

4

Shaft

Stainless Steel

5

Sleeve Bearing*

Teflon/Fiberglass

6

Resilient Seat*

Buna-N

7

Seat Retaining Ring Stainless Steel

8

Ret. Ring Screws* Stainless Steel

9

Taper Pin

Stainless Steel

10

Taper Pin O-Ring* Buna-N

11

Taper Pin Nut

Stainless Steel

12

Taper Pin Washer Stainless Steel

13

Packing*

Buna-N

14

Key

Carbon Steel

15

Thrust Bearing Cap Ductile Iron

16

Cap Screws

Carbon Steel, Plated

17

Thrust Brg. Stud

Bronze

18

Thrust Plate

Cast Iron

19

Thrust Plate Bolt

Carbon Steel. Plated

20

Thrust Plate Gasket Non-Asbestos Fiber

21

Lock Cap

Cast Iron

22

Lock Cap Bolts

Carbon Steel, Plated

23

Lock Cap Gasket

Non-Asbestos Fiber

24

Body O-Ring

Buna-N

*Recommended Spare Part

VALVE CONSTRUCTION

The standard Series 2000 Butterfly Valve is

constructed of rugged cast iron with a stainless steel

shaft and resilient disc edge. See the specific

Materials List submitted for the order if other than

standard cast iron construction. The details of

construction are illustrated in Figure 2.

The body (1) is available with flanged or mechanical

joint ends for connection to the pipeline. The body is

equipped with a stainless steel seat (2). The 1/4 turn

disc (3) is guided by a stainless steel shaft (4) which

rotates in non-metallic bearings (5) fixed in the body.

Leak-tight closure is made when the resilient seat (6) is

rotated into the stainless steel seat on the "SEAT END"

of the body.

TABLE 1. STANDARD VALVE PARTS LIST

FIGURE 2. STANDARD BUTTERFLY VALVE CONSTRUCTION