Val-Matic 4-20 Air/Vacuum Valve With Optional Anti-Slam Valve User Manual

Page 5

4

4. Lift float (5) from body. Turn guide

bushing (9) to remove it from body (1).

5. Clean and inspect parts. Note: some

floats contain sand for extra weight; if

water is detected, replace float.

Replace worn parts as necessary and

lubricate parts with FDA grease.

Remove all foreign matter from body

and cover.

REASSEMBLY

All parts must be cleaned and gasket surfaces

should be cleaned with a stiff wire brush in the

direction of the serrations or machine marks.

Worn parts, gaskets and seals should be

replaced during reassembly.

1. Apply thread sealant Loctite 680 to

guide bushing threads (9) and thread

bushing into body (1).

2. Lay seat (4) over inverted cover with flat

surface directed toward cover. Fasten

to cover with screws (8). Tighten

fasteners per Table 3.

3. Install float (5) through bushing (9).

4. Apply a gasket compound such as

Garlock 101-S to both sides of gasket.

Lay cover gasket (6) and cover (2) over

bolt holes in body (1).

5. Insert lubricated bolts (7) and tighten to

the torques listed in Table 3.

Size Torque (ft-lbs)

1/4" 6

5/16” 11

3/8” 19

7/16” 30

1/2" 45

5/8” 93

3/4" 150

7/8” 202

Table 3. Valve Bolts Torques

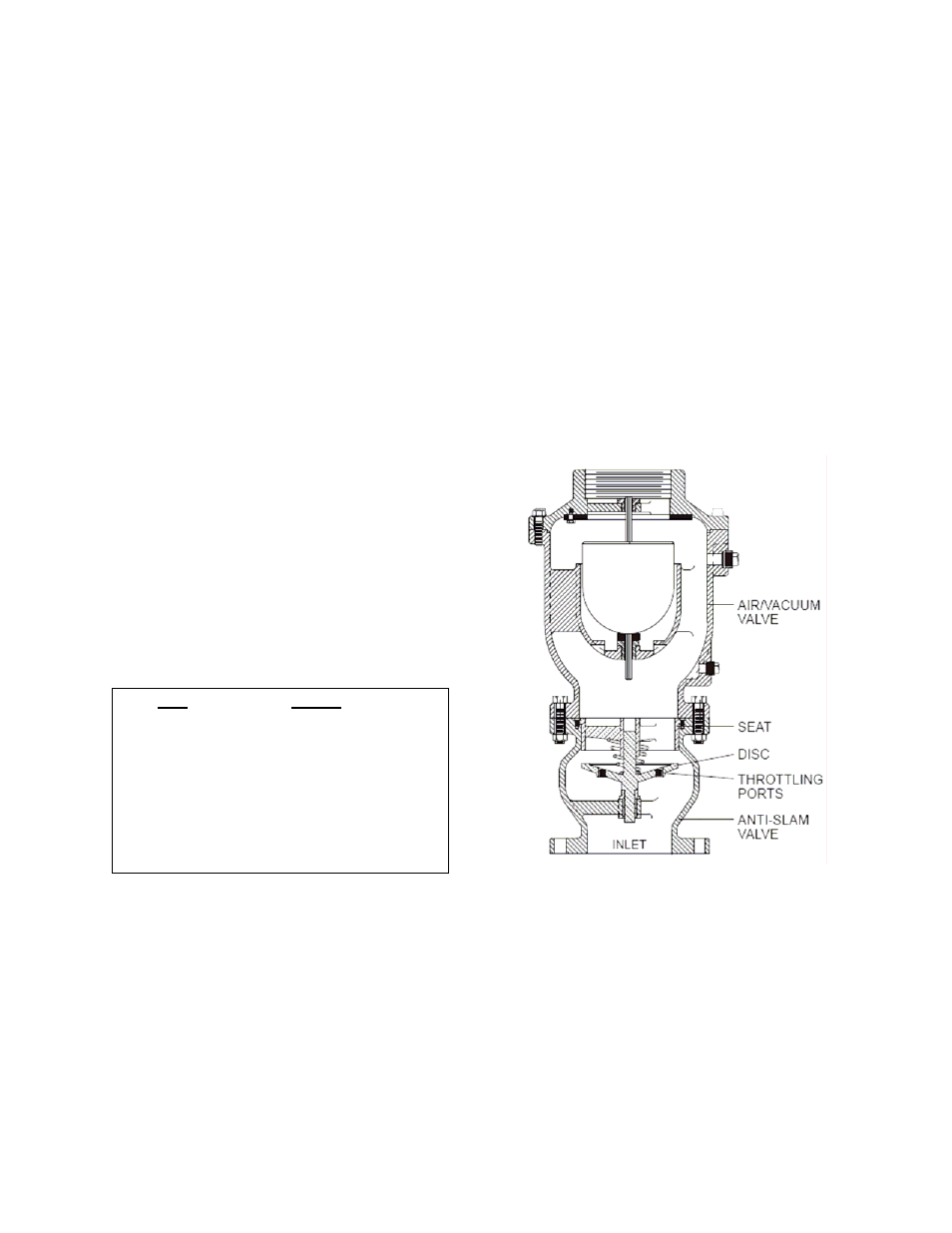

OPTIONAL ANTI-SLAM VALVE

DESCRIPTION OF OPERATION: Air/Vacuum

valves may be factory equipped with an anti-

slam valve on the inlet port as shown in Figure

4. The purpose of the valve is to prevent the

air/vacuum valve from being slammed shut

during critical operation such as after a sudden

pipeline flow stoppage.

The anti-slam valve is normally open and allows

unrestricted flow

of air in and out of the

air/vacuum valve. However, when water enters

the valve, it raises the disc to the closed

position. The passage of water is throttled

through small ports in the disc, which reduces

the possibility of shocks and water hammer.

Figure 4. Optional Anti-Slam Valve