Val-Matic 4-20 Air/Vacuum Valve With Optional Anti-Slam Valve User Manual

Page 4

3

Item Description Material

1 Body

Cast

Iron

2 Cover

Cast

Iron

4 Seat*

Buna-N

5 Float*

Stainless

Steel

6 Gasket*

Non-Asbestos

7

Cover Bolt

Alloy Steel

8

Retaining Screw

Stainless Steel

9

Guide Bushing*

Stainless Steel

15 Cushion*

Buna-N

23

Hood Assembly

(optional)

Iron, Steel

27

Washer*

(8”-20” valves)

Stainless steel

28

Pipe Plug

Malleable Iron

*Recommended Spare Part

Table 2. Air/Vacuum Valve Parts List

MAINTENANCE

The Air/Vacuum Valve requires no scheduled

lubrication or maintenance.

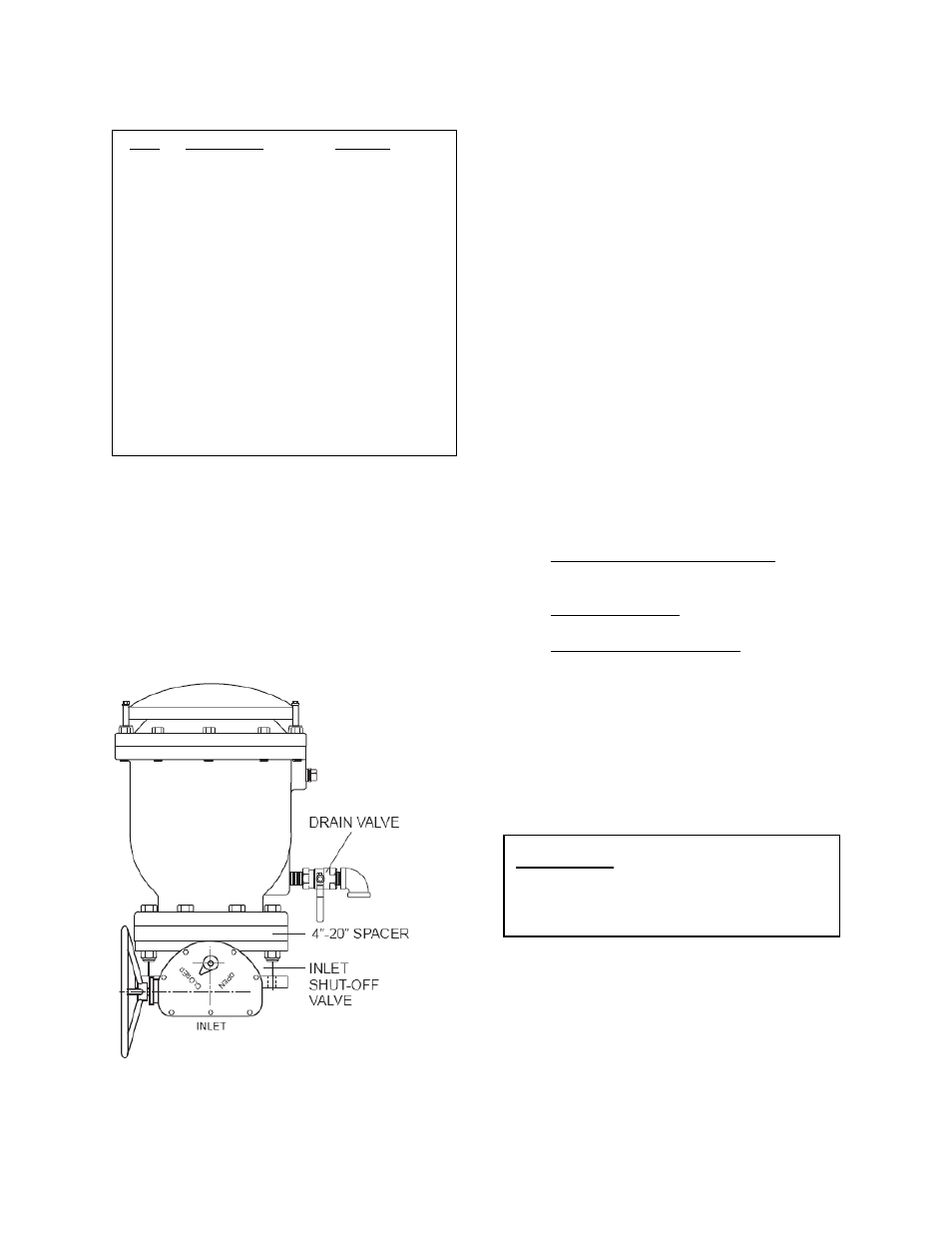

INSPECTION: Periodic inspection for leakage

can be performed. A manual drain valve can be

installed in the lower drain plug to perform this

operation as shown in figure 3.

Figure 3. Inspection Piping

To verify valve function, refer to Figure 3 and:

1. Crack open the drain valve until any air

trapped in the valve is relieved. Close

the drain and the inlet shutoff valve.

2. Open the drain valve to allow the fluid in

the valve to drain. It may be necessary

to apply a downward force on the float

to unseat the valve.

3. Close the drain valve.

4. Slowly open the inlet shutoff valve to fill

the valve with water. Observe the

seating action and verify that the valve

closes without leakage.

5. If leakage occurs, the valve should be

removed and inspected for wear or

possible damage from foreign matter.

TROUBLESHOOTING

Several problems and solutions are presented

below to assist you in troubleshooting the valve

assembly in an efficient manner.

1. Leakage at Bottom Connection: Tighten

valve flanged connection. If leak persists,

remove valve and replace gasket.

2. Leakage at Cover: Tighten bolts, replace

gasket.

3. Valve Leaks when Closed: Inspect seat

for damage and replace.

DISSASSEMBLY

The valve can be disassembled without

removing it from the pipeline. Or for

convenience, the valve can be removed from the

line. All work on the valve should be performed

by a skilled mechanic with proper tools. Refer to

Figure 2.

1. Close inlet shutoff valve. Open drain

valve or remove drain plug. Remove

hood if needed.

2. Remove the cover bolts (7) on the top

cover. Pry cover (2) loose and lift off

valve body.

3. Remove retainer bolts (8) and inspect

seat for cracks in rubber or wear in

sealing surface.

WARNING:

The valve must be drained

before removing the cover

or pressure may be

released causing injury.