Val-Matic 4-20 Air/Vacuum Valve With Optional Anti-Slam Valve User Manual

Page 3

2

INSTALLATION

The installation of the valve is important for its

proper operation. The valves must be installed

at the system high points in the vertical position

with the inlet down. For pipeline service, a vault

with freeze protection, adequate screened

venting, and drainage should be provided.

During closure, some fluid discharge will occur

so vent lines should extend to an open drain for

in-plant installations. A shutoff valve should be

installed below the valve in the event servicing is

required. A spool piece is required when mating

to a wafer butterfly valve.

FLANGED ENDS: Flanged valves should be

mated with flat-faced pipe flanges equipped with

resilient gaskets. When ring gaskets are used,

the bolt material shall be ASTM A307 Grade B

or SAE Grade 2 carbon steel.

Lower the valve over the mating flange using

slings or chains around the valve body.

Lubricate the flange bolts or studs and insert

them around the flange. Lightly turn bolts until

gaps are eliminated. The tightening of the bolts

should be done in graduated steps using the

crossover tightening method. Recommended

lubricated torque values, for use with resilient

gaskets (75 durometer), are given in Table 1.

If leakage occurs, allow gaskets to absorb fluid

and check the bolt torque and leakage after 24

hours. Do not exceed bolt rating or crush gasket

more than 50% of its thickness.

Valve

Size

(in)

Bolt

Dia

(in)

Recom.

Torque

(ft-lbs)

Max.

Torque

(ft-lbs)

4 5/8 30 90

6 3/4 30 150

8 3/4 40 150

10 7/8 45 205

12 7/8 45 205

14 1 80 300

16 1 90 300

18 1

1/8 100 425

20 1

1/8 120 425

Table 1. Flange Bolt Torques

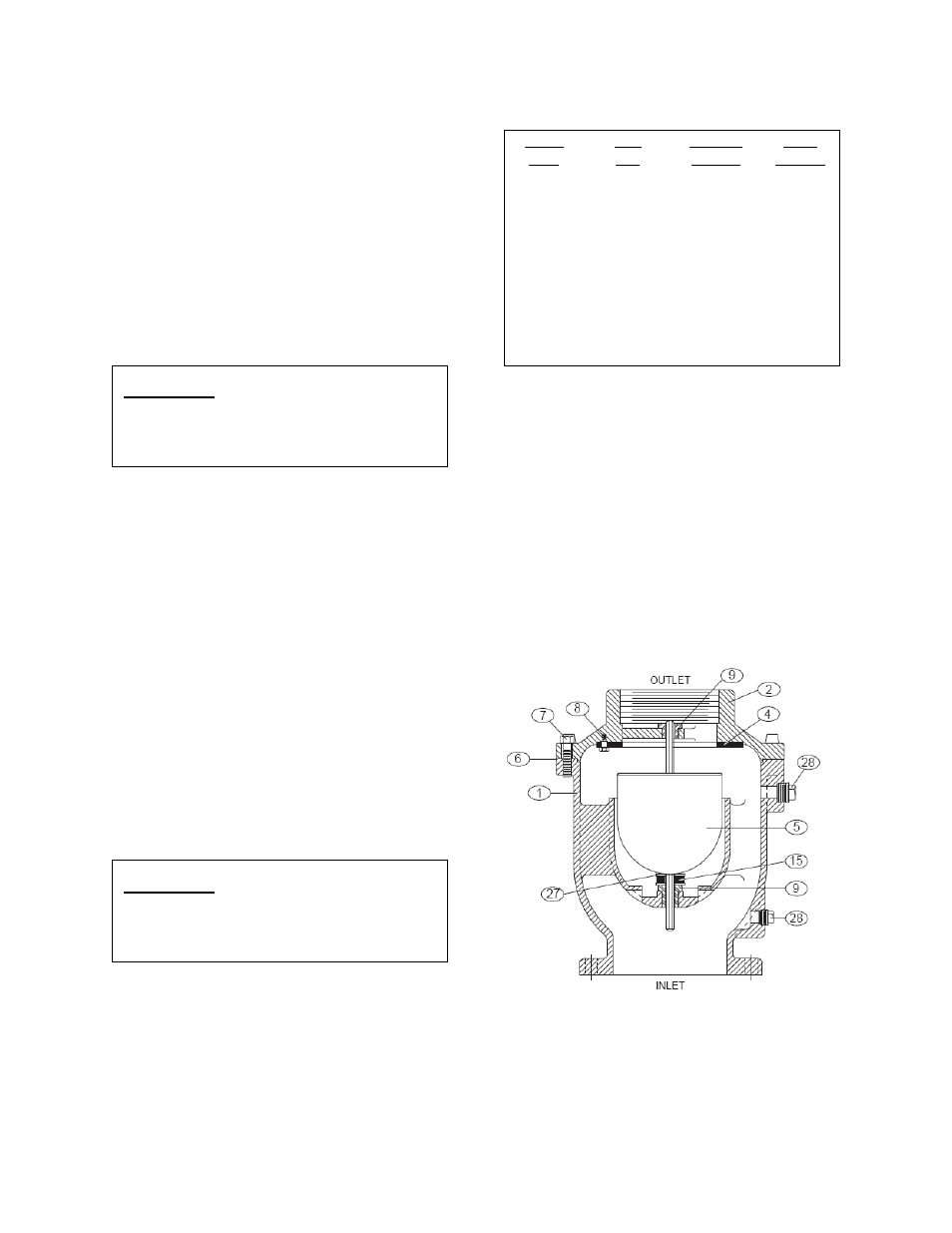

VALVE CONSTRUCTION

The standard Air/Vacuum Valve body and cover

are cast iron. See specific Materials List

submitted for the order if other than standard

cast iron construction. The internal metal

components are stainless steel. The float (5) is

the only moving part assuring long life with

minimal maintenance. The general details of

construction are illustrated in Figure 2. The

body (1) is flanged for connection to the pipeline.

The resilient seat (4) is retained in the cast cover

(2). An optional hood is available.

Figure 2. 4”-20” Air/Vacuum Valve

CAUTION:

Remove packing from

outlet and install valve

with “INLET” port down or

leakage will occur.

CAUTION:

The use of raised-face

flanges or excessive bolt

torque may damage valve

flanges.