Reelcraft Series DGM - Underground Reels User Manual

Page 2

DGM Hose Reels

Page 2

www.reelcraft.com

NOTE: An installation kit, p.n. 600719, is

available to assist in connecting the reel to 1

½” PVC supply pipe.

7. Check the system for leaks. If none,

backfill the hole with drainage stone to the

anti-flotation ring located at the center of

the case. See Figure 3.

8. Replace the cover and backfill the rest of

the hole with loam. Replace the sod or

landscaping.

OPERATION

To access the hose, turn the cover until the

notches in both the cover and riser line up.

Pull up on the cover to remove. The hose may

be pulled out to any desired length. After use,

pull or carry all of the hose back to the reel

opening. The hose may damage grass or land-

scaping if allowed to retract unassisted. Feed

the hose into the reel carefully to prevent the

hose from piling up in the center of the reel. A

slight side-to-side motion works best when the

hose is being retracted.

ADJUSTMENT

WARNING: Use extreme caution; reel under

tension. Avoid releasing latch mechanism.

If necessary, adjust spring tension on reel by

manually adding or removing wraps of hose

from spool, one wrap at a time, until desired

tension is obtained. Manually add wraps to

increase tension. Remove wraps to decrease

tension.

CAUTION: When adding wraps of hose, add

just enough wraps to achieve the desired ten-

sion without exceeding the drive spring wind-

ing capacity. Properly tensioned reels allow

all hose to be freely removed from the spool.

The drive spring will be damaged if it is over

tensioned.

SERVICE INSTRUCTIONS

User servicing of the reel is limited to replacing

the hose, without removing the reel from the

ground. If other repairs are required, consult

an authorized service person.

HOSE REPLACEMENT

Shut off inlet water supply, and bleed pressure

from hose. Pull all of the main hose out of

the opening. The main hose is connected to

a leader hose with a threaded fitting. Pull the

leader hose out just until the threaded fitting is

accessible, and the latch mechanism is engaged

to prevent hose retraction. Remove the main

hose by unthreading the connection. Attach the

replacement hose to the leader hose.

NOTE: Thread sealant is not required on this

connection only. Be sure to use the hose end

with tapered pipe threads for this connection.

Tighten the threaded connection. Turn on water

supply and check for leaks. If leaks are found,

tighten threaded connection. Pull on the main

hose to disengage the latch mechanism. The

hose should retract normally.

NOTE: Replacement hoses may require some

assistance in retraction for a few uses to wind

onto the spool without piling or tangling.

REEL REMOVAL

Shut off inlet water supply, and bleed pressure

from hose. Remove the sod and loam from the

top cover of the reel vault.

NOTE: It is not necessary to remove the vault

from the installation for repairs to the reel. Re-

move the cover screws, and remove the cover.

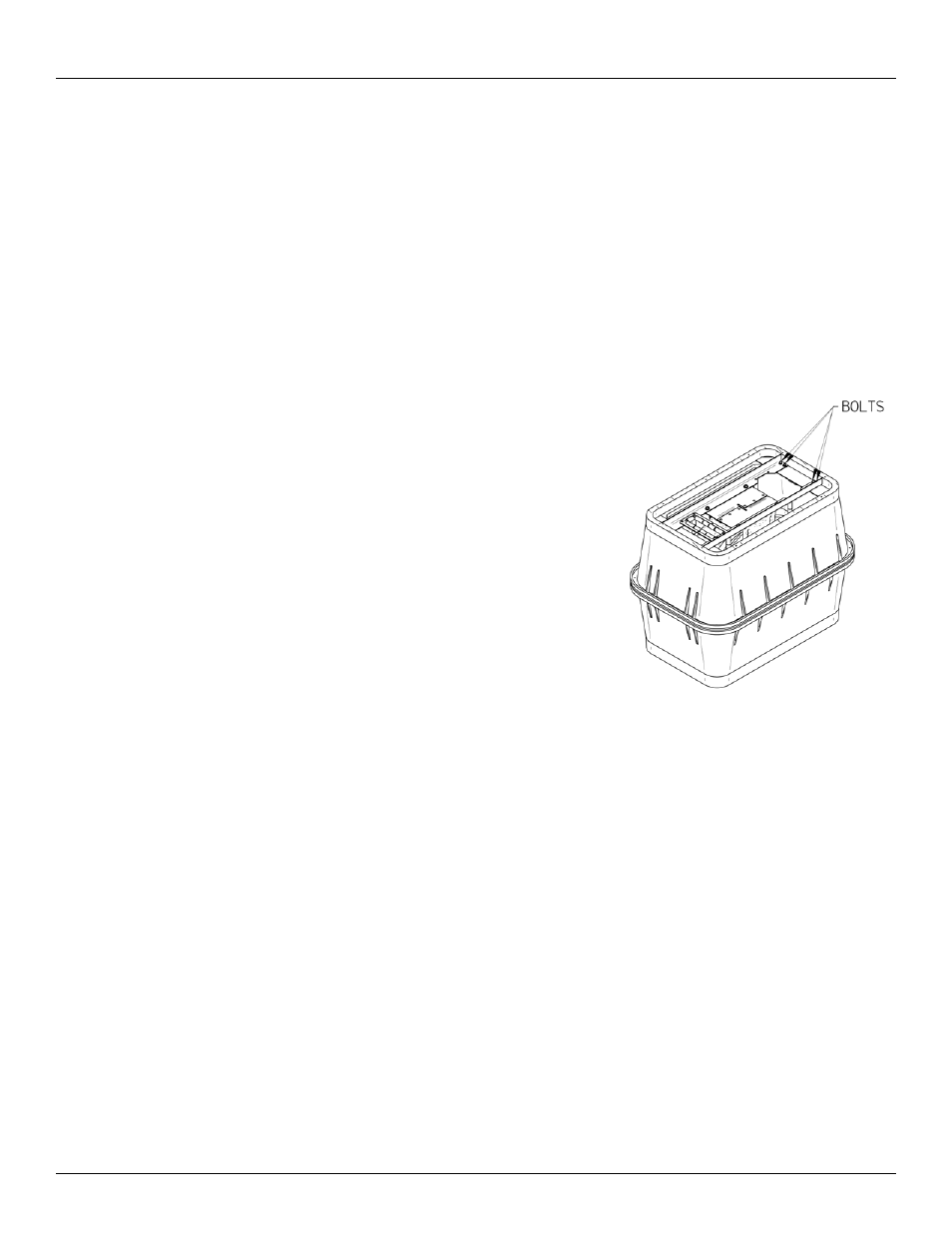

Remove the eight bolts from the cross rails.

See Figure 2. Slide the reel to permit access to

the inlet hose. Remove the inlet hose from the

swivel. Pull reel vertically out of the vault. If

necessary, the reel cover, loam, and sod may be

replaced for aesthetic purposes.

REEL REPLACEMENT

Remove sod, loam, and reel cover. Lower reel

into vault, and slide to the side to allow access

to the inlet hose. Connect the inlet hose using

thread sealant. Position the reel so it is cen-

tered in the vault, and the mounting holes align.

Secure with at least 4 bolts shown in Figure 2.

NOTE: The bolts shown in Figure 2 are primar-

ily installed to prevent damage during ship-

ment. These bolts are normally not required

after installation. Turn on the water supply to

check for leaks. Bleed air out of hose. If leaks

are found, tighten connections, or repair as

necessary. After reel has been tested, replace

the lid, using the existing screws. Replace the

loam and sod.

Figure 2