Rapid-Air PALLET MASTER (PMDH): PMDH35 & PMDH50. 115VAC, 1PH, 60HZ User Manual

Page 4

4

Mechanical Operating Procedure

To Load or Unload a Coil Ring

The PMD can handle any coils that are on a pallet, table diameter is 42 inches for the PMD-35

and 51 inches for the PMD-50 and max 3500 lbs on a PMD-35 and MAX 5000 lbs on a PMD

50, but only up to 30 inches in height from the table top.

Step 1:

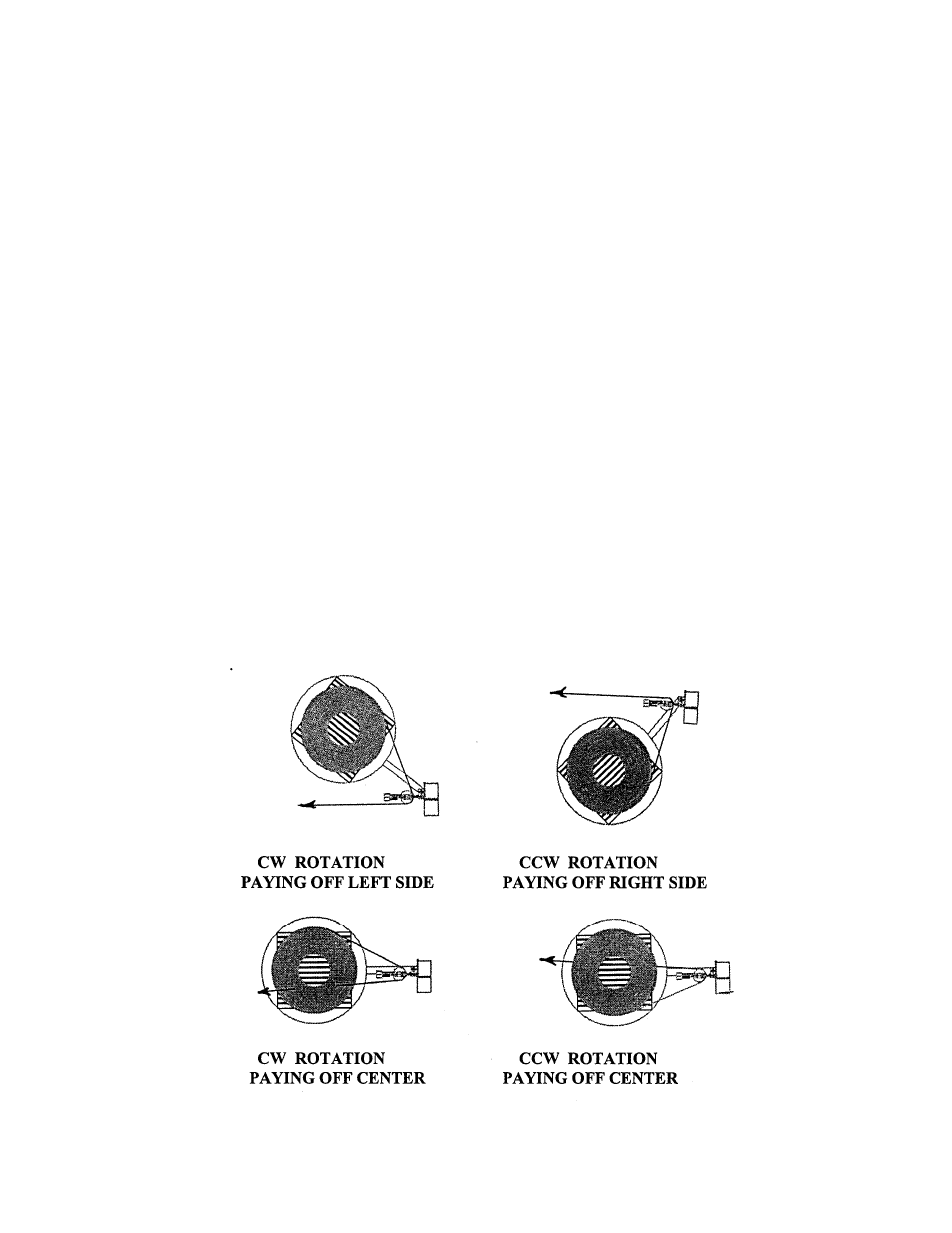

Decide if the material that is paying out will go over the table or beside the table and which side

of the table. If all the coils are wrapped the same way then choose a side that will be in line

with the press and don’t forget the ease of loading of the pallets. If the coils are wrapped so the

table direction has to be switched to unwind the next coil then over the top will be best other-

wise the PMD will have to be moved to pay off the other side as the material flow is the oppo-

site way.

Step 2:

Make sure the arm is clear of the loading zone and load the pallet onto the table. Align the pal-

let so it is in the center of the table. Adjust the dancer arm roller assembly so that it is even

with or slightly above the coil that is being unwound. Jog the table around so the end is within

reach from the operator station and stop. Cut the material free and grab the loose end and then

jog the table around so the material can be threaded in behind the roller. When there is suffi-

cient material available, the PMD can be put into “run” and as the material is walked to the ma-

terial work station the PMD will rotate and keep up.

.