Specifications – Rapid-Air STRAIGHTENER / RAPID-ROLL: SA3 - SD with compact control User Manual

Page 6

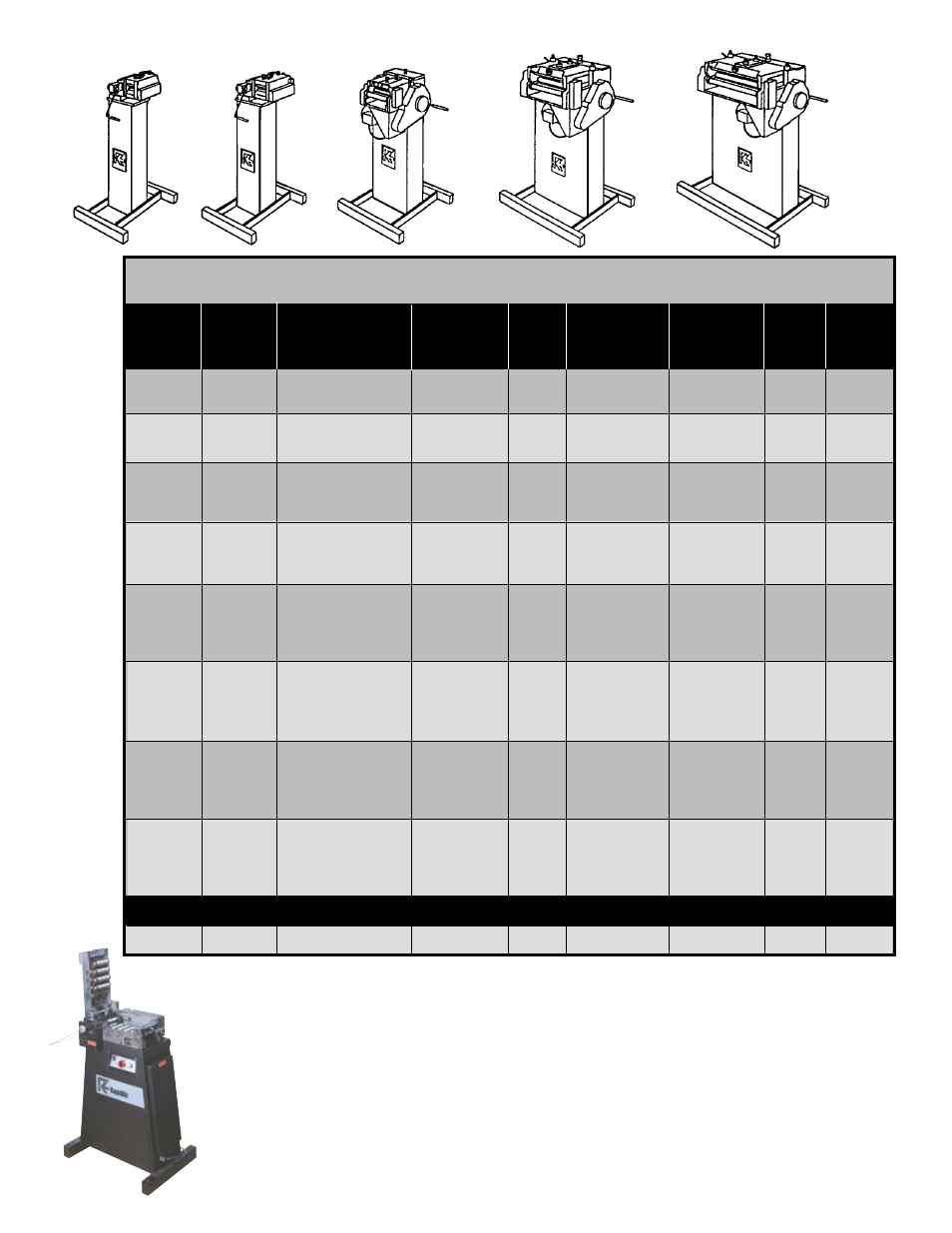

SpecificationS

SA

Series

SB

Series

SBX

Series

SCX

Series

SD

Series

Model SC4 Straightener with individually adjustable upper

rolls. This 4” x .085” capacity straightener with its coun-

terbalanced swing-open top is a Rapid-air original and

continues to be available due to customer acceptance and

demand. Dial-type indicators for roll settings are optional.

A noTe on RoLL DiAMeTeR AnD qUAnTiTy:

The smaller the roll diameter in a straightener the better

it is able to remove distortions in the strip of material.

Rapid-Air straighteners are designed to optimize all

factors (including number of rolls, diameter and position)

within the published material capacities and specifica-

tions for each model.

Model SC4

Max

Effective

Max

Straightening

Pinch

Drive

Input

Material

Straightening

Speed

Rolls

Rolls (2)

Motor

Power

Model

Width

Range

per min

Speed

No., Dia.

Dia.

(HP)

(vac/ph)

sa3

3” (76mm)

.002” - .030” (.051-.76mm)

700” (1778cm)

Standard 11, 3/8 (9.53mm)

1-1/2 (38.1mm)

1/4

115/1

sa3M

3” (76mm)

.002” - .030” (.051-.76mm)

1,400” (3556cm)

Medium

11, 3/8 (9.53mm)

1-1/2 (38.1mm)

1/2

115/1

sB4

4” (102mm) .003” - .050” (.076-1.27mm)

700” (1778cm)

Standard 11, 5/8 (15.86mm)

1-1/2 (38.1mm)

1/2

115/1

sB4M

4” (102mm) .003” - .050” (.076-1.27mm)

1,400” (3556cm)

Medium

11, 5/8 (15.86mm)

1-1/2 (38.1mm)

1/2

115/1

sBX4

4” (102mm)

.004” - .080” (.10-2.03mm)

825” (2100cm)

Standard 9, 7/8 (22.23mm)

1-3/4 (44.45mm)

3/4

115/1

sBX8

8” (203mm)

.004” - .070” (.10-1.78mm)

825” (2100cm)

Standard 9, 7/8 (22.23mm)

1-3/4 (44.45mm)

3/4

115/1

sBX12

12” (305mm)

.004” - .060” (.10-1.52mm)

825” (2100cm)

Standard 9, 7/8 (22.23mm)

1-3/4 (44.45mm)

3/4

115/1

sBX4M

4” (102mm)

.004” - .080” (.10-2.03mm)

1,650” (4200cm)

Medium

9, 7/8 (22.23mm)

1-3/4 (44.45mm)

1

115/1

sBX8M

8” (203mm)

.004” - .070” (.10-1.78mm)

1,650” (4200cm)

Medium

9, 7/8 (22.23mm)

1-3/4 (44.45mm)

1

115/1

sBX12M

12” (305mm)

.004” - .060” (.10-1.52mm)

1,650” (4200cm)

Medium

9, 7/8 (22.23mm)

1-3/4 (44.45mm)

1

115/1

scX6

6” (152mm)

.006” - .100” (.15-2.54mm)

825” (2100cm)

Standard 9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

1

115/1

scX12

12” (305mm)

.006” - .090” (.15-2.29mm)

825” (2100cm)

Standard 9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

1

115/1

scX18

18” (457mm)

.006” - .080” (.15-2.03mm)

825” (2100cm)

Standard 9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

1

115/1

scX24

24” (610mm)

.006” - .065” (.15-1.65mm)

825” (2100cm)

Standard 9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

1

115/1

scX6M

6” (152mm)

.006” - .100” (.15-2.54mm)

1,650” (4200cm)

Medium

9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

2

230/1

scX12M

12” (305mm)

.006” - .090” (.15-2.29mm)

1,650” (4200cm)

Medium

9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

2

230/1

scX18M

18” (457mm)

.006” - .080” (.15-2.03mm)

1,650” (4200cm)

Medium

9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

2

230/1

scX24M

24” (610mm)

.006” - .065” (.15-1.65mm)

1,650” (4200cm)

Medium

9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

2

230/1

scX6h

6” (152mm)

.006” - .080” (.15-2.03mm)

4,100” (10400cm)

High

9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

3

230/1

scX12h

12” (305mm)

.006” - .070” (.15-1.78mm)

4,100” (10400cm)

High

9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

3

230/1

scX18h

18” (457mm)

.006” - .060” (.15-1.52mm)

4,100” (10400cm)

High

9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

3

230/1

scX24h

24” (610mm)

.006” - .055” (.15-1.40mm)

4,100” (10400cm)

High

9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

3

230/1

sd6

6” (152mm)

.006” - .125” (.15-3.18mm)

825” (2100cm)

Standard 9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

2

230/1

sd12

12” (305mm)

.006” - .125” (.15-3.18mm)

825” (2100cm)

Standard 9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

2

230/1

sd18

18” (457mm)

.006” - .100” (.15-2.54mm)

825” (2100cm)

Standard 9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

2

230/1

sd24

24” (610mm)

.006” - .090” (.15-2.29mm)

825” (2100cm)

Standard 9, 1-3/8 (34.93mm)

1-3/4 (44.45mm)

2

230/1

A right-to-left material flow direction is standard for above models –– left-to-right optional at no additional cost.

sc4

4” (102mm)

.015” - .085” (.38-2.13mm)

825” (2100cm)

Standard 9, 1-1/4 (31.75mm)

1-1/4 (31.75mm)

1

115/1