Adjustments and control functions, Ramm adjustments and control functions – Rapid-Air STRAIGHTENER / RAPID-ROLL: SA3 - SD with compact control User Manual

Page 19

WARNING: if adjustments are made

under power, insulated adjustment

tools must be used and eye protection

must be worn.

The RAMM has been factory adjusted

to provide 0-full speed using the

speed control knob. Minimum and

Maximum speed trimpots are provid-

ed to change the speed from other

than 0-full speed. The Acceleration

(ACCeL) trimpot is provided to allow

for a smooth start over an adjustable

time period each time the AC power is

applied or the speed pot is rotated.

The DeCeL trimpot controls the amount

of ramp-down when the speed pot

is adjusted to a lower speed. The

Current Limit (CL, or torque output)

adjustment is factory set to approxi-

mately 1-1/2 times the motor rating.

The iR Compensation (iR) is factory

adjusted to provide excellent motor

regulation under normal operation.

NOTE: in order for the iR comp and

CL trimpot settings to be correct, the

proper Plug-in Horsepower Resistor

must be installed for the particular

motor and input voltage being used.

Do not attempt to change the settings

of the trimpots unless absolutely

necessary since they are factory

adjusted to near optimum settings.

The following procedure, presented in

order of adjustment sequence, should

be used when readjusting all trimpot

functions.

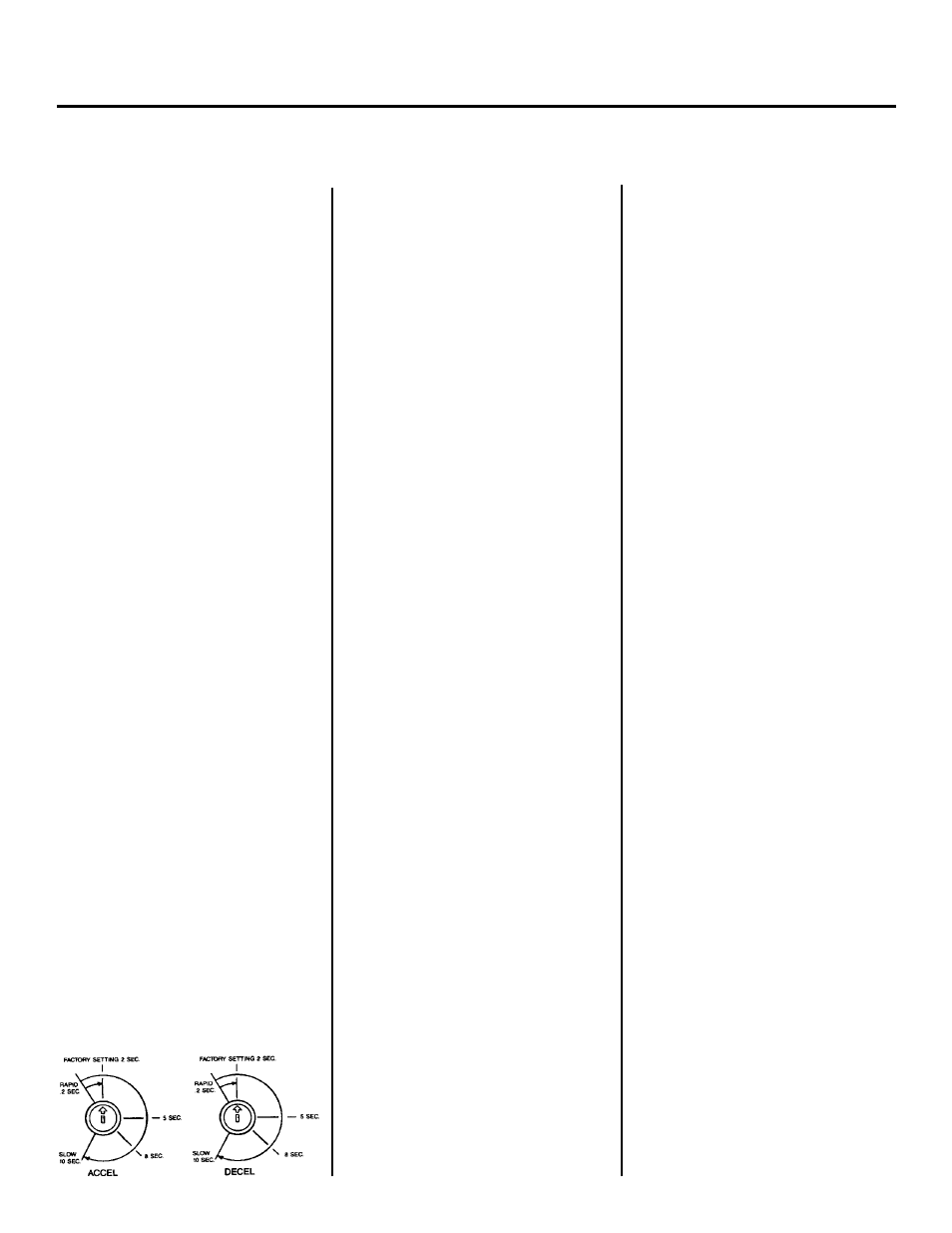

FIGURE 2: ACCEL/DECEL

Trimpot ADJUSTMENT

A. Acceleration Start. The ACCeL

is factory set at approximately

.2 seconds. To readjust to

different times, set the knob to the

desired position as indicated in Fig 2.

B. Deceleration. The DeCeL is

factory set to provide a ramp-

down time of .2 seconds. To

change the ramp-down time,

adjust the DeCeL trimpot as

indicated in Fig 2.

C. Minimum Speed Adjustment. if a

higher than zero minimum speed

is desired, readjust the minimum

speed by turning the speed control

knob to zero setting (full CCW

position). Then adjust the Min.

Speed trimpot to the desired setting.

NOTE: The min. speed adjustment

will affect the max. speed setting.

Therefore, it is necessary to readjust

the max. speed after the min. speed is

adjusted.

D. Maximum Speed Adjustment. Turn

Speed Control Knob to full speed

(maximum CW position). Adjust max.

speed trimpot to new desired setting.

NOTE: Do not attempt to adjust the

max. speed above the rated motor

RPM since unstable motor operation

may occur. For moderate changes in

the max. speed, there will be a slight

effect on the min. speed setting.

e. Current Limit (CL/Torque Adjust-

ment). CL circuitry is provided to

protect the motor and control

against overloads. The CL also limits

the inrush current to safe level

during startup. The CL is factory

set to approximately 1.5 times the

full load rating of the motor. (CL

trimpot is nominally set to ap-

proximately 65% of full CW rotation).

To set the CL to factory specifications

adjust as follows:

1. Set speed control knob at approxi-

mately 30-50% CW rotation. Set CL

trimpot to full CCW position.

2. Connect a DC ammeter in series

with the armature lead.

3. Lock shaft of motor (be sure CL

pot is in full CCW position).

Apply power and rotate CL pot CW

slowly until DC ammeter reads 1.5

times motor rating (do not exceed 2

times motor rating, Max. CW position.)

NOTE: if only an AC ammeter is avail-

able, it can be installed in series with

the AC line. Follow above instructions;

however, set AC amperage at .75

times motor rating.

F. IR Compensation Adjustment. iR

compensation is provided to sub-

stantially improve load regulation.

if the load presented to the motor

does not vary substantially, the

iR adjustment may be set at a

minimum level (approximately 1/4

of full setting). The control is

factory adjusted to approximately

3% regulation. if superior perfor-

mance is desired (less than 1%

speed change of base speed

from 0 to full load), then the iR

comp. Should be adjusted as follows:

NOTES: 1. excessive iR comp. will

cause control to become unstable,

which causes motor cogging.

2. For tach feedback applications the

iR comp can be set to minimum rota-

tion (full CCW).

1. Set iR comp. trimpot at approxi-

mately 25% of CW rotation. Run

motor unloaded at approximately

1/3 speed and record RPM.

2. Run motor with maximum load and

adjust iR comp. trimpot so that

the motor speed under load equals

the unloaded speed per step 1.

3. Remove load and recheck

unloaded RPM. if unloaded RPM

has shifted, repeat procedure for

more exact regulation.

The RAMM is now compensated to

provide minimal speed change under

large variations of applied load.

adjuStmentS and control functionS

RAMM Adjustments And Control Functions