Powermate 024-0175CT User Manual

Page 5

5 - ENG

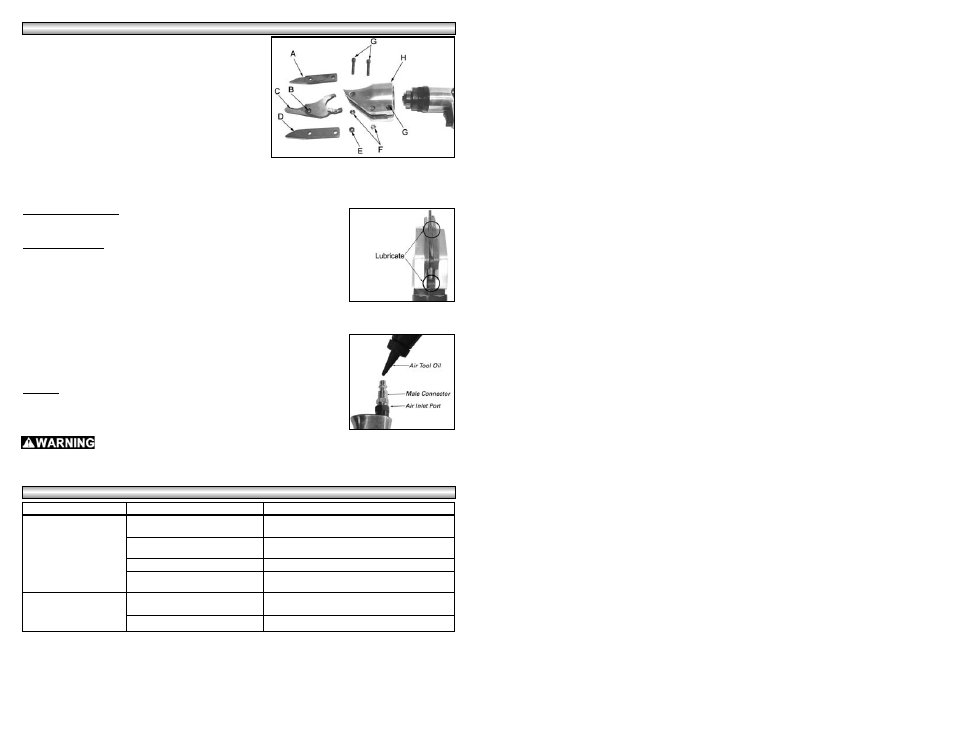

Cutting Head Lubrication

To keep the blades operating smoothly, lubricate the contact points each time you use

the tool (see Figure 6).

Air Motor Lubrication

To maintain the maximum performance of the air tool, it must be lubricated each time

it is used. Dust, dirt, rust and oil residue will build up inside the tool and reduce the perform-

ance. An in-line oiler is recommended for proper automatic tool lubrication (see Figure 1). If

an in-line oiler is not available, the tool can be lubricated manually through the inlet port

(see Figure 7).

1.

Disconnect the air tool from the air supply.

2.

Turn the tool upside down and while depressing the trigger, add 4-6 drops of Coleman Powermate® air tool oil

#018-0059SP or SAE10 nondetergent oil into the air inlet. NOTE: Depressing the trigger helps circulate the oil in the

air motor.

3.

Reconnect the tool to the air supply, cover the exhaust port end with a towel and run

for approximately 30 seconds to remove excess oil. NOTE: If the tool remains

sluggish after it has been lubricated, the internal components may need to be

cleaned.

To Clean:

Disconnect the air tool from the air supply and pour or spray a generous amount of

WD-40® into the air inlet with the trigger depressed. Connect the tool to the air supply,

cover the exhaust port end with a towel and run for approximately 30 seconds. Follow the

air motor lubrication instructions above after cleaning is completed to re-lubricate the tool.

After oiling or cleaning, cover the exhaust port with a towel and operate the tool for a few

seconds to safely remove the excess oil. Clean the handle and surface of the tool of any oil

residue. Failure to cover the exhaust port and clean the tool, can result in serious injury.

Note: Keep the towel away from moving parts!

USER-MAINTENANCE INSTRUCTIONS (continued)

USER-MAINTENANCE INSTRUCTIONS (continued)

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

Figure 7

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Tool will not run or runs

slowly

Grit in tool; tool gummed up

Clean the air motor inside the tool with WD-40®

(see “user maintenance” section).

No oil in tool

Add 4-6 drops of air tool oil into the air inlet of the

tool (see “user maintenance” section).

Low air pressure

Adjust compressor regulator to 90 PSI.

Air hose leaks

Tighten and seal hose fittings with Teflon® tape if

leaks are found.

Rough cut edges or tool

jams

Applying uneven pressure

Apply even pressure. Too much pressure can

cause a rough cut or cause the tool to jam.

Blades are dull.

Replace blades (see “user maintenance” section).

7.

Insert the 3 blades together into the cutting head (H)

aligning the holes closest to the top of the blades with the

top hole in the cutting head (H). Insert an allen screw

through the cutting head (H), 3 blades and then through the

bottom of the cutting head. Thread a nut (F) onto the

bottom of the allen screw. Do not overtighten the allen

screw at this time.

8.

Line up the back holes of the side blades (A & D) with the

center hole in the cutting head (H). Place the spacer (E)

between the blades and insert an allen screw through the

cutting head (H), side blade (A), spacer (E), side blade (D)

and then through the bottom of the cutting head. Thread a

nut (F) onto the bottom of the allen screw. Do not overtighten the allen screw at this time.

9.

Install the assembled cutting head back onto the tool motor.

10.

Tighten all 3 allen screws securely with the allen wrench.

Figure 5

Figure 6