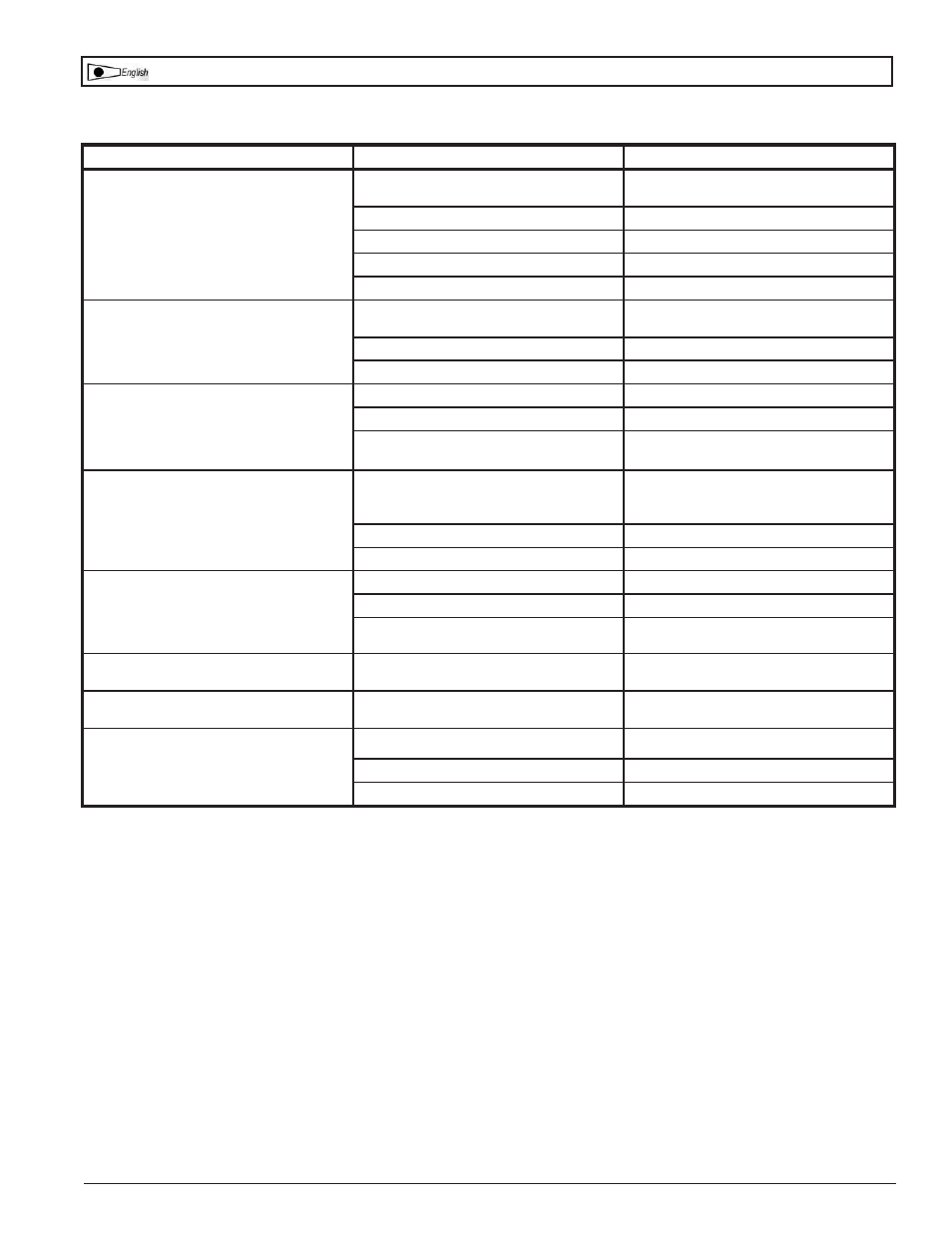

Troubleshooting chart – Powermate CTA5590856 User Manual

Page 20

20

200-2415

Note: Troubleshooting problems may have similar causes and solutions.

PROBLEM

POSSIBLE CAUSE

SOLUTION

Low Discharge Pressure

Air leaks

Tighten or replace leaking fittings or

connections. Do not overtighten.

Leaking valves

Contact authorized service center.

Restricted air intake

Clean or replace air filter element(s).

Blown gaskets

Contact authorized service center.

Worn piston rings or cylinder

Contact authorized service center.

Pump Knocking

Loose engine pulley or compressor

flywheel

Retighten pulley and flywheel. Check

alignment.

Low oil level in pump crankcase

Keep oil at proper level at all times.

Excess carbon on valves or top of piston

Contact authorized service center.

Oil in Discharge Air

Worn piston rings or cylinder

Contact authorized service center.

Restricted air intake

Clean or replace the air filter element(s).

Oil level too high

Reduce to proper level. Use SAE 10W-30

synthetic oil.

Overheating

Poor ventilation

Relocate compressor to an area with cool,

dry, well circulated air, at least 12 in. from

nearest wall.

Dirty cooling surfaces

Clean all cooling surfaces thoroughly.

Restricted air passages

Replace transfer tubes and/or unloader.

Excessive Belt Wear

Pulley out of alignment

Realign pulley with compressor flywheel.

Improper belt tension

Readjust.

Pulley wobbles

Replace the pulley and check for a

damaged crankshaft or flywheel.

Excessive Unloader Cycling

Air leaks in piping

Tighten or replace leaking fittings or

connections. Do not overtighten.

Gasoline Engine Stall

Air leaks in piping

Tighten or replace leaking fittings or

connections. Do not overtighten.

Compressor Won’t Start in Cold

Temperatures

Compressor not winterized

See cold weather preparation.

Engine flooded

Remove spark plug and dry it. Reinstall.

Compressor too cold

Move compressor to a warmer location.

TROUBLESHOOTING CHART