Operation, General safety information (cont.), Equipment use – Paasche Airbrush GT-PL User Manual

Page 2

GT-25 Instructions and Parts List

12. Always shut off air pressure at

source and bleed off all pressure in

paint tank by turning pressure

release valve before loosening

knobs.

13. Regularly check to be sure gauge

and regulator are functioning

correctly. Also check that no paint or

other deposits are in the safety valve

inlet. In the event more than 60 psi is

applied to the tank and the safety

valve is clogged, the higher pressure

could damage the tank or result in

injury.

Do not spray flammable

materials in vicinity of

open flame or near

ignition sources including the

compressor unit.

14. Do not smoke when spraying paint,

insecticides, or other flammable

substances.

15. Use a face mask/respirator when

spraying and spray in

a well ventilated area

to prevent health and

fire hazards.

16. Do not direct paint or other sprayed

material at the compressor. Locate

compressor as far away from the

spraying area as possible to

minimize overspray accumulation on

the compressor.

17. When spraying or cleaning with

solvents or toxic chemicals, follow

the instructions provided by the

chemical manufacturer.

Failure to follow

instructions on

proper assembly and use of a paint

tank may possibly result in damage to

property or personal injury. This unit

must be assembled as indicated in

these instructions. only parts

supplied with this unit should be

used. These parts are safety

performance engineered. use only

oEM replacement components.

EQUIPMENT USE

This paint tank is designed to be used

with a spray gun.

TO USE A SPRAY GUN

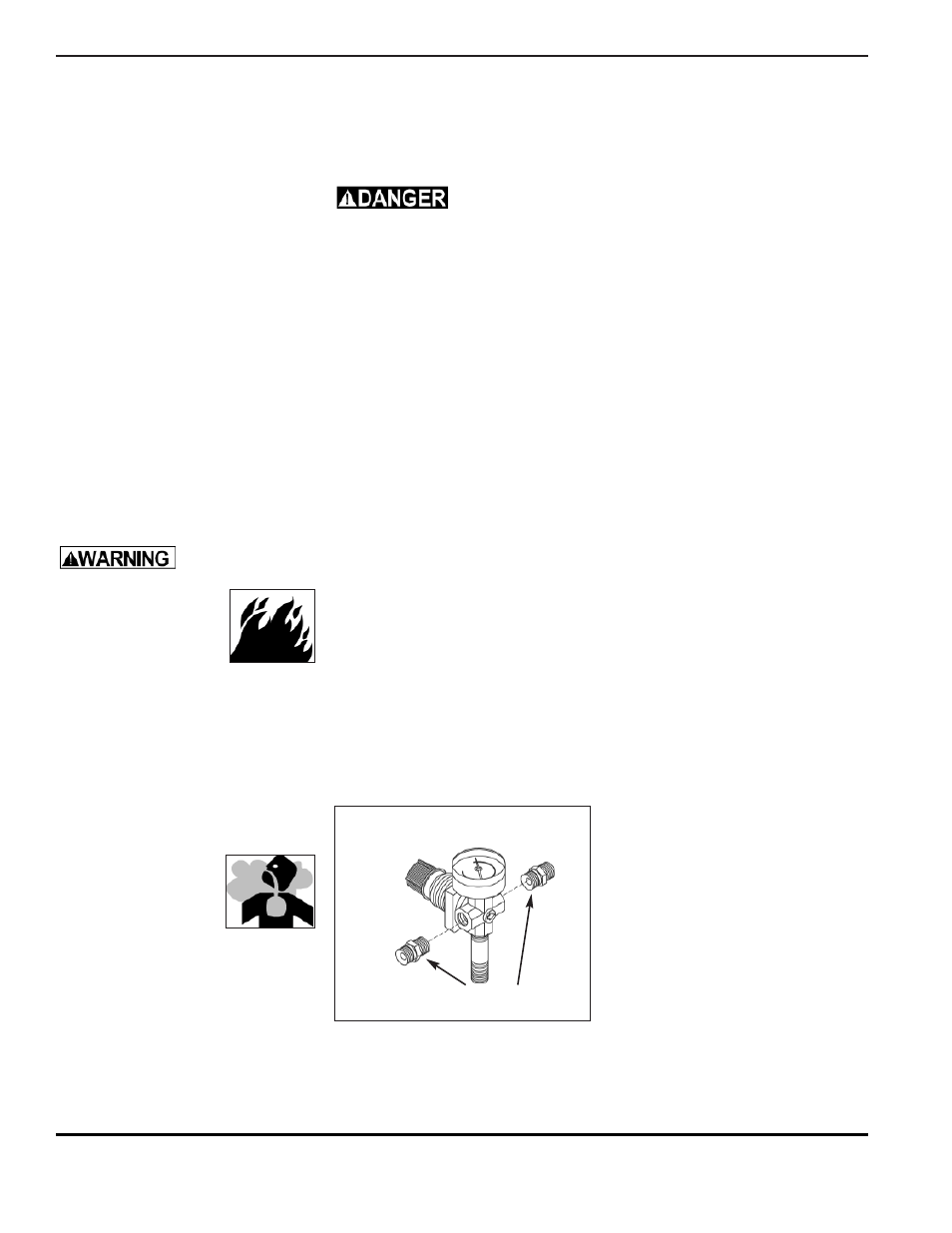

1. Install the two hose connectors into

the remaining ports of the tank

regulator.

2. Attach the air supply hose (not

Included) to the 1/4” NPT air inlet

connector of regulator (back side of

arrow).

3. Attach an air hose between the

regulator out port and the spray gun

air inlet.

NOTE: A 15 ft. air hose and 15 ft.

material hose between the paint tank and

spray gun is recommended. Up to 25 ft.

of air hose may be used between the

paint tank and the compressor. A longer

length may create a large pressure drop.

1. Before using the tank for the first time,

the seal and bracket position should

be established by pre-pressurizing the

tank.

a. Connect the material hose to the

spray gun.

b. Connect the air hose from

regulator to the spray gun or cap.

c. Before filling the tank with paint

material, evenly tighten the knobs

so that the lid is secure and sealed.

d. Close the paint tank regulator by

turning fully counterclockwise, then

open the air regulator on the

source to deliver air to the paint

tank regulator.

e. Increase paint tank pressure by

turning the knob clockwise until 30

psi reads on the tank regulator

gauge.

f. Check for leaks in the system. If a

fitting leaks, depressurize the tank

by shutting off the air at the air

source regulator and turning the

knob on the pressure release valve

until air no longer hisses from it.

Tighten the leaking fitting, then

open the air source regulator to

deliver 30 psi into the paint tank

Figure 3

Hose connectors

Air OUT to

spray gun

(unregulated)

Air IN

General Safety

Information (Cont.)

www.paascheairbrush.com

Operation

2