Spray gun operation – Paasche Airbrush GT-PL User Manual

Page 3

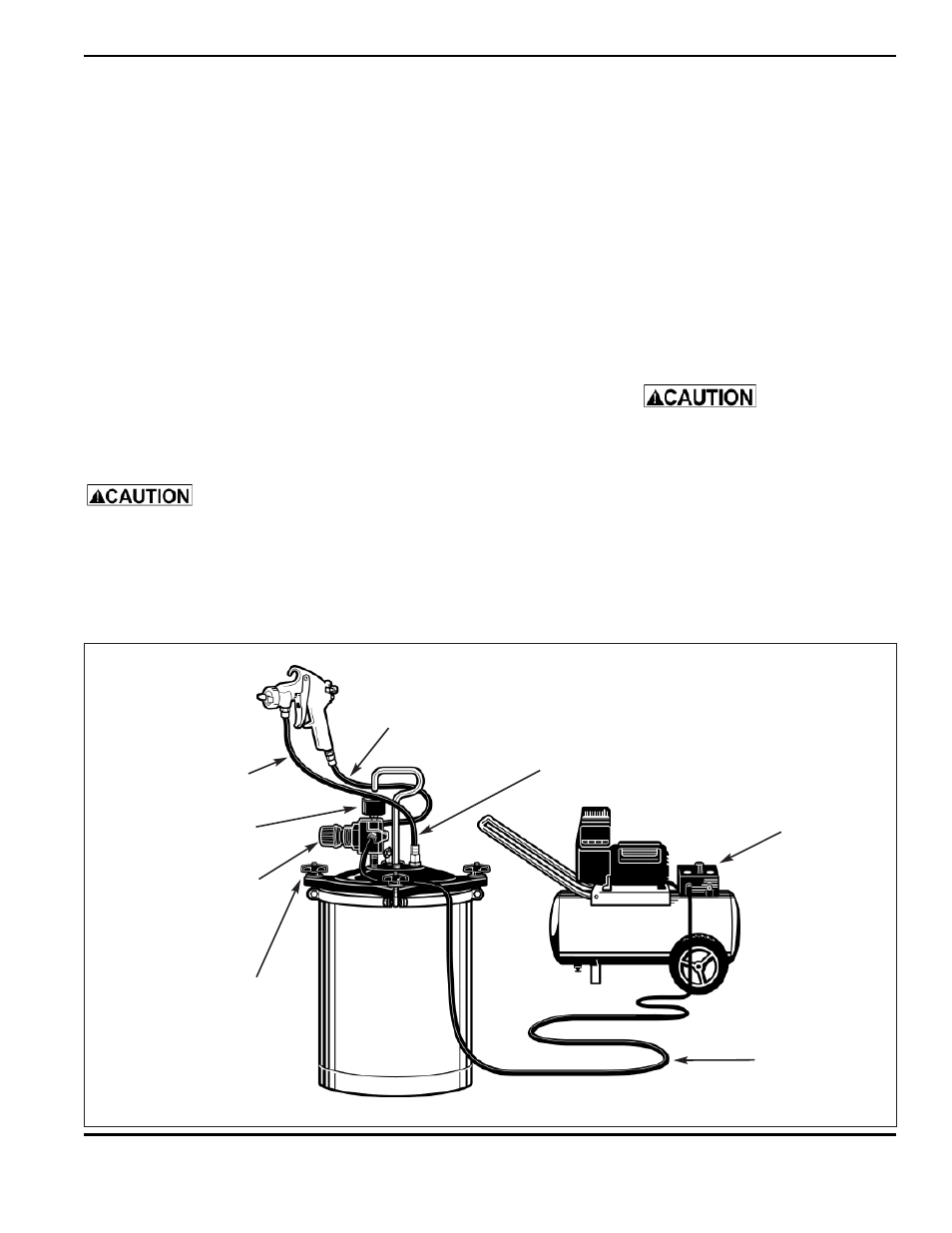

Air source

regulator

Material hose

Air hose

Air hose

Material

hose

Figure 5

Paint tank

regulator

Knob

Pressure

gauge

INSTRUCTIONS & PARTS LIST GT-25

www.paascheairbrush.com

3

compounds. These materials will damage

the gasket between the paint tank and lid.

A damaged gasket may cause injury and

will reduce the efficiency of the paint tank.

3. Place lid on paint tank then tighten

knobs evenly and gradually.

DO NOT USE WRENCh OR PLIERS TO

TIGhTEN kNOBS. hAND TIGhTEN

ONLY.

4. Turn pressure off at the air source

regulator by turning counterclockwise.

Pressure gauge should read 0 psi.

5. Shut off paint tank regulator by

turning counterclockwise.

SPRAY GUN OPERATION

1. Adjust air source regulator pressure

required for spraying (usually

between 30-40 psi).

and material hose.

g. Depressurize system by shutting

off air supply, then gently turning

the knob on the pressure release

valve to relieve the pressure in the

system.

2. The tank may now be filled with

material. Before filling, thoroughly mix

and strain the paint to remove skins

or undissolved particles which might

otherwise impede the flow of material

through the hose and gun. A one

gallon can of paint can be set inside

the tank instead of pouring the paint

into the tank.

Never use this

paint tank with

materials which contain trichloroethane,

chlorinated hydrocarbons, nitrohydro-

carbons, esters, amines, or organic

2. Adjust paint tank regulator to 25-30

psi. More pressure is needed on the

material as the gun is moved further

above the tank. Normal operating on

the paint tank is 5 to 10 psi. When

lower pressure is needed, rotate the

adjustment counterclockwise until the

desired pressure setting is obtained.

There is no need to trigger the gun in

order to bleed off excess paint

pressure. The sprayer may now be

used to apply paint.

Do not use over 60

psi in the tank.