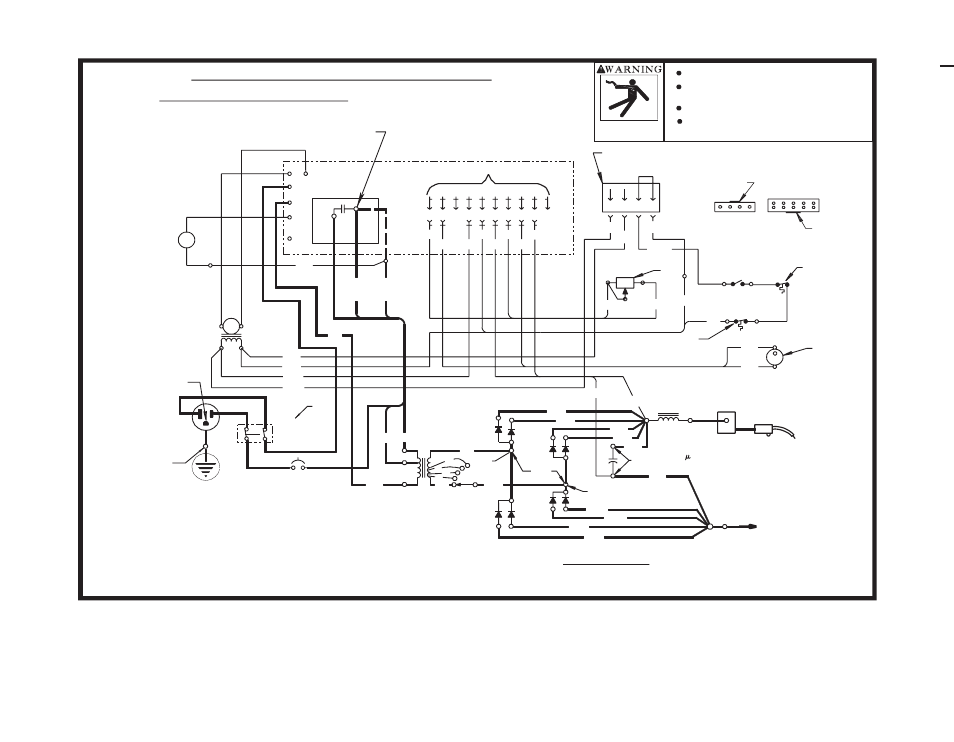

Mig pak 15 wiring diagram – Lincoln Electric IMt552 MIG-PAK 15 User Manual

Page 57

57

ELECTRICAL SYMBOLS PER E1537

CAVITY NUMBERING SEQUENCE

( COMPONENT SIDE OF BOARD )

539

541

213

GUN TRIGGER

THERMOSTAT

208

5K

WIRE SPEED

R2

(W)

(B)

N.C.

209

214

211

WINDING

24V

AUXILIARY

FAN MOTOR

H2

541

204

203

209

208

539

213

214

1 2 3 4

LATCH

5

6 7 8 9 10

1

2

3

4

5

6

7

8

9 10

GAS

SOLENOID

CONTROL P.C. BOARD

J1

CR1

H1

H2

LS1

H2

H2

D3

204

204

204

203

203

203

C1

40V

203

204

-

+

GUN CABLE

CONDUCTOR

BLOCK

TO

WORK

T1

N.B.

N.A.

X1

202

X2

S2

SELECTOR

SWITCH

OUTPUT

CHOKE

X4

X5

+

H1

N.A. DIODES D1,D3,D5 & D7 ARE MOUNTED

ON THE OUTSIDE HEATSINK.

D1

D5

D2

D6

D7

D4

D8

X3

X6

204

204

203

203

H2

N.O.

208V/60HZ

H3

230V/60HZ

N.C.

H3

HIGH VOLTAGE

can kill

Only qualified persons should install, use or

service this machine.

Do not operate with covers removed.

Do not touch electrically live parts

Disconnect input power by unplugging

power cord before servicing

CUSTOMER VOLTAGE RECONNECTION FOR DUAL VOLTAGE MACHINE

TO EARTH GROUND

PER NATIONAL, LOCAL

OR OTHER APPLICABLE

ELECTRICAL CODES.

G

N.D.

N.D.

211

THERMOSTAT

+

-

MACHINES ARE SHIPPED FROM FACTORY CONNECTED FOR 230V AS SHOWN. TO CONNECT WELDER FOR

208V INPUT, DISCONNECT WELDER FROM INPUT POWER, REMOVE CASE SIDE, REMOVE LEAD MARKED "H1"

H1

(230V)

H3

(208V)

LEAD COLOR CODE:

B-BLACK

W-WHITE

(MOUNTED TO

SEC. COIL)

(MOUNTED TO

DIODE HEATSINK)

WIRE

FEED

MOTOR

CIRCUIT

BREAKER

N.B. DIODES D2,D4,D6 & D8 ARE MOUNTED ON THE INSIDE

HEATSINK, WHICH IS CLOSEST TO THE CENTER PANEL.

CASE

GROUNDING

STUD

N.C. COMPONENT VIEWED FROM REAR.

S1

ON-OFF

SWITCH

93,000 f

N.D. BOLTED ALUMINUM CONNECTIONS REQUIRE T12837 JOINT

COMPOUND (DOW CORNING 340) WHEN REATTACHING.

MIG PAK 15 WIRING DIAGRAM

M17879

1

2

3

4

J3

LATCH

1

2

3

4

214

211

213

JUMPERED PLUG STANDARD

SPOT/STITCH TIMER OPTIONAL

213A

211

214

J1

J3

FROM CR1. REMOVE TAPE SECURING H3 LEAD ASSEMBLY TO INPUT CORD AND CONNECT H3 TO CR1.

INSULATE UNUSED H1 TERMINAL LEAD FOR 300V WITH ELECTRICAL TAPE AND SECURE TO INPUT CORD.

REINSTALL CASE SIDE BEFORE CONNECTING INPUT POWER. RECONNECTION TO 230V IS REVERSE OF

ABOVE PROCEDURE. SEE INSTRUCTION MANUAL FOR DETAILS.

9-20-96F

NOTE: This diagram is for reference only. It may not be

accurate for all machines covered by this manual.

The specific diagram for a particular code is pasted

inside the machine on one of the enclosure panels.

NOTA: Ce schéma n'est donné qu'à titre de référence. Il

peut ne pas être exact pour toutes les machines

traitées dans ce manuel. Le schéma particulier

pour un code spécial est collé à l'intérieur de la

machine sur un des panneaux du boîtier.

NOTA: Este diagrama es sólo para referencia. Es posible

que no sea exacto para todas las máquinas que se

mencionan en este manual. El diagrama específico

para su máquina se localiza dentro de la misma, en

uno de los páneles.