Operation – Lincoln Electric IMT10049 WIRE FEEDER WELDER 125, 140 User Manual

Page 12

B-3

OPERATION

B-3

WIRE FEEDER WELDERS (125, 140 MODELS)

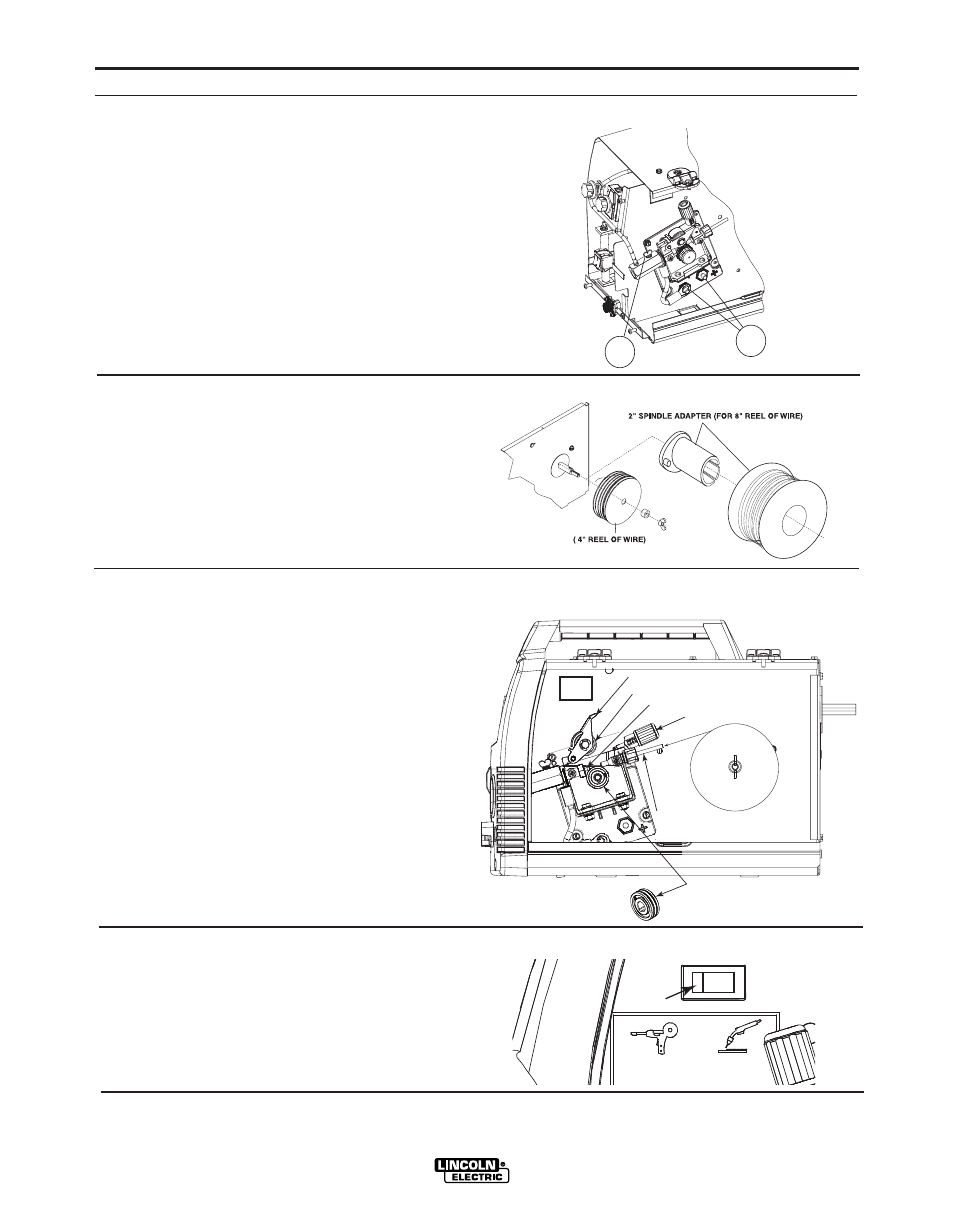

See Figure B.3

8. WELDING GUN CONNECTOR BUSHING &

THUMBSCREW – Provides electrical power to the

welding gun. The thumbscrew holds the welding

gun into the connector block. (Front Cover and Side

Door have been removed for clarity of Items 8 and

9).

9. OUTPUT TERMINALS - Connections to these ter-

minals determines the welding polarity, depending

on whether the process being used is flux-cored

welding or MIG welding.

See Figure B.4

10. WIRE SPOOL SPINDLE AND BRAKE – Holds a

4”(102mm) diameter spool. Use the 2”(51mm)

spindle adapter included with the machine for 8”

(203mm) diameter spools. The wing nut sets the

brake friction to prevent the spool from over rotat-

ing when the trigger is released. Tightening the

wing nut will prevent the spool from rotating when

the trigger is released.

See Figure B.5

11. WIRE DRIVE & COMPONENTS – Feeds wire

from the wire spool through the drive and through

the welding gun to the work piece.

a. Drive Roll – Drives the wire through the drive

system. The drive roll has grooves to match the

specific wire type and diameter. Refer to Table

B.1 for available drive rolls.

b. Incoming & Outgoing Guide – The wire is fed

through both guides. The Pivot Arm Assembly,

Tension Arm Assembly and Drive Roll keep

pressure on the wire in the groove.

c. Tension Arm Assembly – Turning clockwise

increases the forward force on the wire and turn-

ing counterclockwise decreases the force.

8

9

FIGURE B.3

FIGURE B.4

FIGURE B.5

FIGURE B.5a

WIRE SPOOL

.035" (0.9mm)

NR-211-MP

DRIVE ROLL

PIVOT ARM ASSEMBLY

TENSION ARM ASSEMBLY

OUTGOING GUIDE

INCOMING GUIDE

BEARING

See Figure B.5a

Magnum 100SG / Magnum 100L Switch - The spool

gun switch is available on 140 Amp machines only.

The Magnum 100SG Spool Gun can be purchased at

authorized retailers. The part number is K2532-1.

MAGNUM 100SG

SWITCH

MAGNUM 100L