Troubleshooting, Caution – Lincoln Electric IM10101 MAGNUM PRO ROBOTIC TORCH K2646-,K2647- User Manual

Page 17

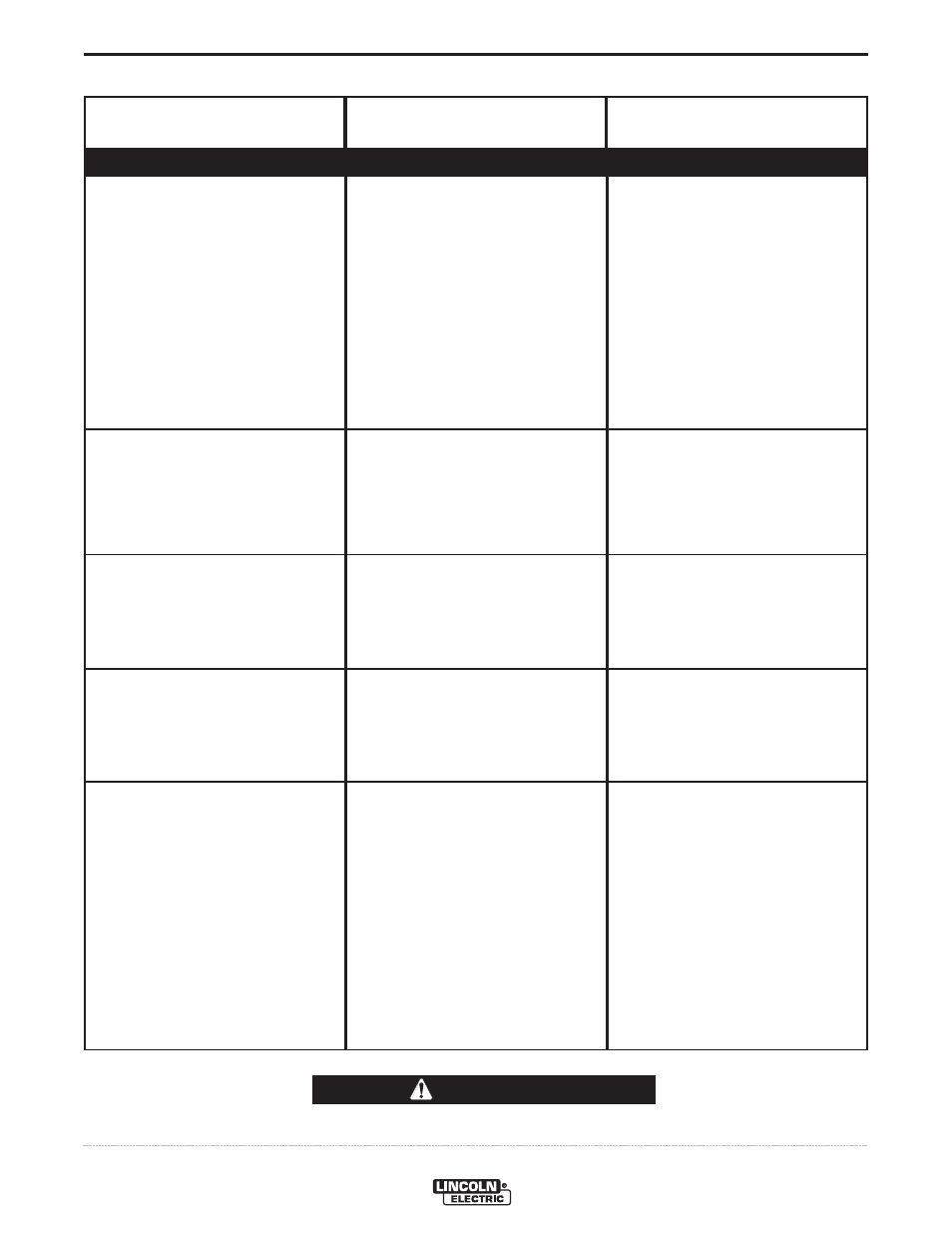

TROUBLESHOOTING

MAGNUM® PRO ROBOTIC TORCH

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local

Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE CAUSE

REMEDY

Frequent birdnesting or kinking of

wire in the gun cable.

Frequent occurrence of contact tip

burnback.

Poor weld bead appearance.

Gun Overheating.

1. Wire shavings/lubricant is building

up in the cable.

2. Cable liner is too large for wire

size.

3.

Mechanical resistance to wire

feeding is too large.

1. Improper welding parameters or

technique (example: ESO

[Electrode Stick Out] is too short).

2. Wire may be feeding intermittently.

1. Improper electrode polarity.

2. Improper welding parameters or

technique.

1. Gun maybe beyond recommend-

ed amperage.

2. Water may not be flowing properly.

1. Clean cable or replace cable liner.

2. Install the smallest possible liner

which is specified for the wire

being used (i.e. use a .052-1/16

liner instead of a 1/16-5/64 liner

when welding with 1/16” diameter

wire.

3. Reposition robot so that cable is

less twisted or bent.

1. See welding wire literature for

proper settings.

2. See symptoms on intermittent or

sluggish wire feed.

1. Reconnect machineʼs welding out-

put to proper electrode polarity.

2. See welding wire literature for

proper settings.

1. See duty cycle chart for recom-

mended amperage.

2. Check that water cooler is turned

on, check water lines for leaks.

E-3

E-3