Maintenance – Lincoln Electric IM281 MAGNUM X-Tractor 1G User Manual

Page 14

C-3

MAINTENANCE

C-3

2.Lift off the top end bracket from the motor.

Be careful not to lose the bearing pre-load

spring washer.

Lift the cylindrical motor

cover up from the motor, slide back on the

leads and tilt away from motor.

3.Locate brushes on opposite sides of the

commutator. Using a 1/4” socket or nut dri-

ver, remove two #8-32 hex head screws from

each brush holder retaining bracket and

remove brackets.

4.Move brush holder assemblies away from

commutator in order to remove coil leads

from brush holders.

10.Place motor cover over motor. Make sure

the bearing spring washer is on top of the

armature bearing and positioned to fit into

bearing seat in the top end bracket.

11.Position the top end bracket so the bolt

slots are directly over the threaded holes in

motor frame.

Place the #10-24 x 2.0"

screws through the slots and install loosely

using a 5/16" socket or nut driver. Rotate

the top end bracket to align heads of the

screws with the marks at the slots made in

Step c.1 and tighten.

d. Replacement of Housing Assembly

Attach motor leads and install housing assem-

bly in the reverse order of Step b.

e. Run-in of Brushes

After replacing brushes, run smoke exhaust

unit on low idle for 30 minutes. Unit is on low

idle when power cable is energized, power

switch is on, and control (#31 and #4) cable is

not connected.

See S17238 included with replacement motor for

instructions for complete vacuum motor replacement.

X-TRACTOR 1G

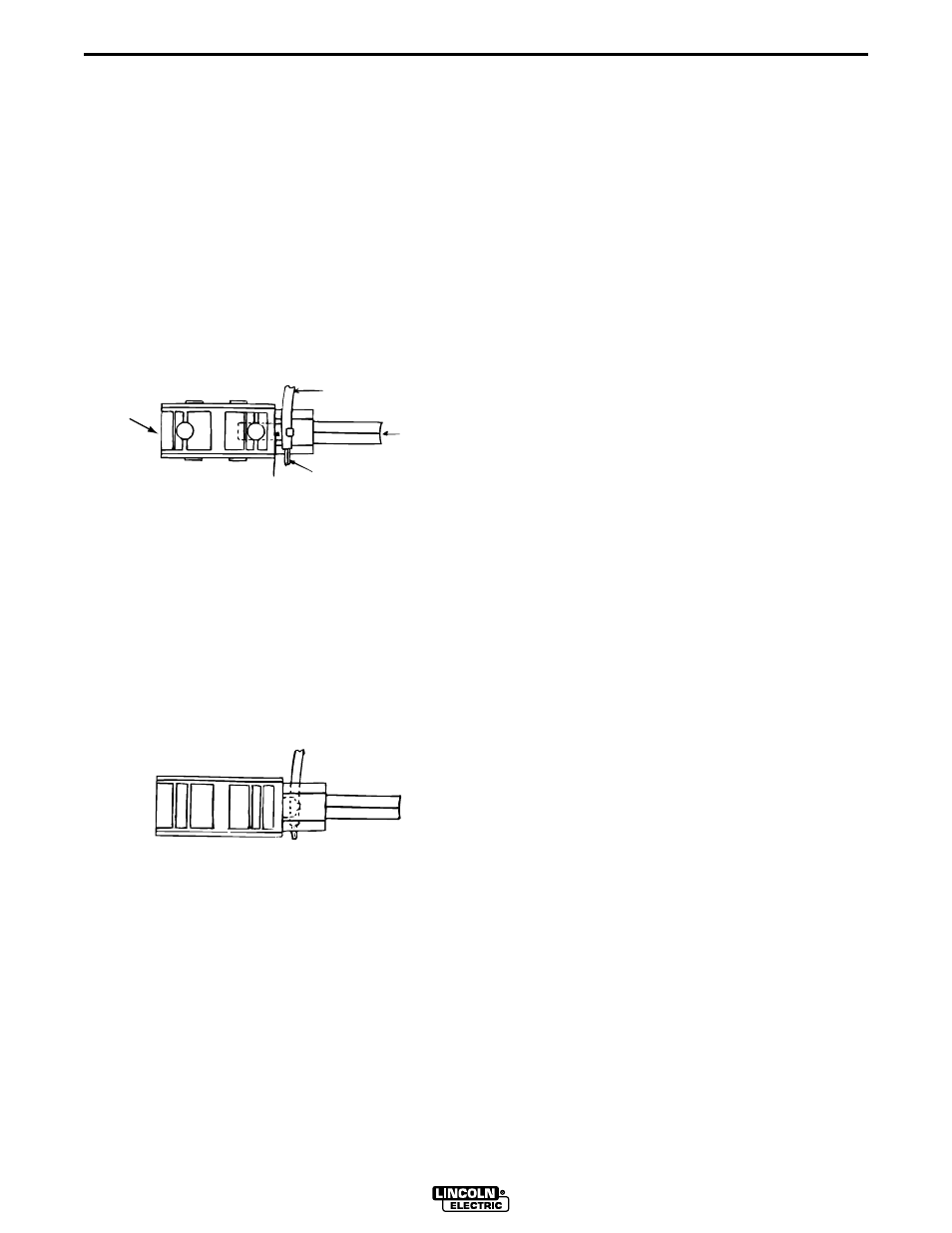

TOP VIEW

BRUSH

HOLDER

COIL

LEAD

BRUSHES

A

B

FIGURE 5

BOTTOM VIEW

C

FIGURE 6

5.Place a screwdriver in area A to pry lead

from brush holder assembly. Do not pry or

pull on bare section of lead denoted by B in

Figure 5.

6.To install new brushes, push tab on each coil

lead into the slot on either side of brush hold-

er. Do not bend the bare section of lead (B).

7.Place each brush assembly in position on

bottom motor housing with coil lead on top.

8.The brush assembly will be properly posi-

tioned when the raised round locater in the

brush area of the bottom housing fits into the

indented section on the brush assembly that

is marked "C" in Figure 6. The brass portion

of the brush holder will be approximately 1/8"

from the commutator.

9.With the brush assembly in position, place

brush hold down bracket over each brush

holder. Start the four #8-32 hex head screws

by hand to avoid cross-threading. Tighten

screws with a 1/4” socket or nut driver.