Operation, Wire feed speed units, Wire feed speed knob – Lincoln Electric IM10080 RED-D-ARC LN-25 PRO EXTREME DUAL POWER User Manual

Page 26: Trigger connector, Work sense lead, Set-up menu

B-6

OPERATION

B-6

RED-D-ARC LN25™ PRO EXTREME DUAL POWER

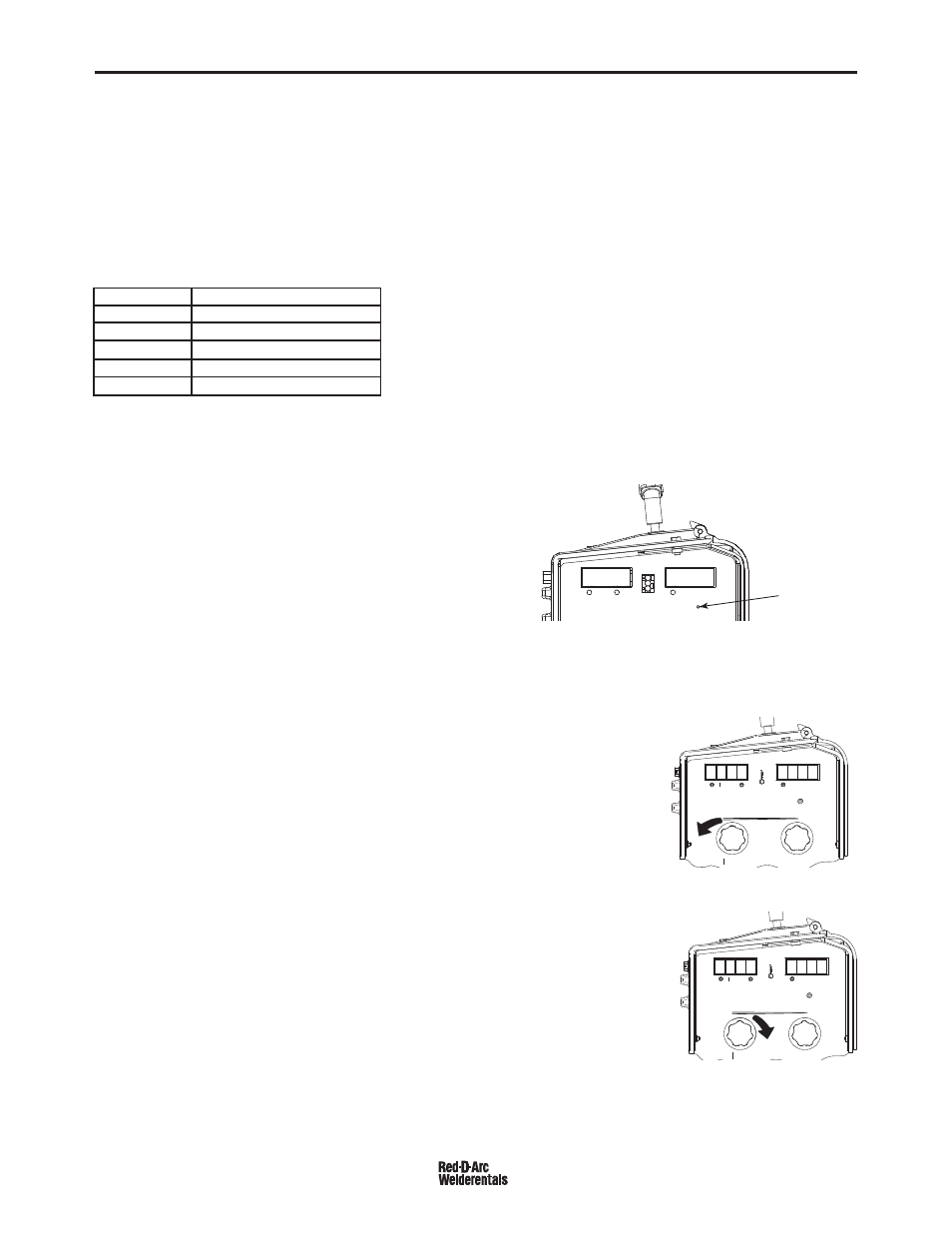

WIRE FEED SPEED UNITS

Rotate the WFS knob to

the left to use

“inches/minute” for the

wire feed speed units.

Rotate the WFS knob to

the right to use

“meters/minute” for the

wire feed speed units.

Press the set-up button to enter the WFS calibration

menu.

US

V

A

O O

O O WFS

LN-25 PRO

U o

r

E

V

A

O O

O O WFS

LN-25 PRO

2. WIRE FEED SPEED KNOB

Use the Wire Feed Speed Knob to adjust the rate of

wire feed speed.

Because the wire feeder is powered by the arc volt-

age, the full range of wire feed speed may not be

available at low voltages. While welding, the display

will show actual wire feed speed. If the actual WFS is

less than set WFS, then the arc voltage may be too

low for procedure.

Arc Voltage

Max WFS (std torque)

15V

280 ipm

17V

340 ipm

21V

440 ipm

24V

520 ipm

27V

600 ipm

3. TRIGGER CONNECTOR

(See Installation Section for Details)

4. WORK SENSE LEAD

Always turn power off at the welding power source

before moving the work sense lead.

The work sense lead attaches to the item being weld-

ed.

Preparation for Amperage Calibration:

Connect the feeder to a power source and grid.

Adjust the power source and grid to the desired

amperage. (example: 220 Amps)

Record the amperage display on the wire feeder.

(example: 210 amps)

To enter the set-up menu, use paper clip to press the

small button located on the case front.

5. SET-UP MENU

Preparation for WFS Calibration:

• Place the CV/CC switch in CV.

• Set the display to the desired wire feed speed

(example: 400 inches per minute)

• Measure the actual wire feed speed (example: 405

inches per minute)

• Place the WFS knob in the 12 oʼclock position.

Pushbutton